Anti-corrosion ointment used for steel structures and preparation method of anti-corrosion ointment

An anti-corrosion and steel structure technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as the inability to guarantee long-term anti-corrosion performance, and achieve low-level requirements, good construction tolerance, and high construction efficiency. The effect of flexible and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for an anti-corrosion paste for steel structures, comprising the following steps:

[0030] (1) Add base oil and adhesive to the double planetary stirring tank, turn on the heating and mixer, and heat until the temperature of the material reaches 85°C;

[0031] (2) Keep the condition at 85°C, stir at 400rpm-800rpm for 15min-25min, then add antioxidant, dispersing penetrant, hydrogenated castor oil derivative, fumed silica, pigment and shell powder in turn under stirring state, Then at 80°C-100°C and 800rpm-1200rpm for 60min-75min;

[0032] (3) Stop heating and pump the material into the kneader, turn on the kneader and cool down to below 50°C, then add the sterilant and corrosion inhibitor in sequence, knead for 100-120min after adding, stop the machine to discharge the material and pack it into the warehouse.

[0033] The anti-corrosion paste for steel structure includes the following components in parts by weight: 15 to 40 parts of base oil, the b...

Embodiment 1

[0036] Aiming at the problems such as crevice corrosion, fretting corrosion, stress corrosion, microbial corrosion and secondary corrosion currently existing in the connection parts of steel structures, the present invention proposes the following anti-corrosion solutions.

[0037] A semi-solid anti-corrosion paste for steel structure, its composition is calculated by percentage: bran oil 15%, hydroxyl-terminated polybutadiene 19.2%, pharmaceutical grade vaseline 4.8%, antioxidant 1010 0.6%, anti-oxidant Oxygen agent BHT 0.2%, flufenapyramide 2.7%, pyraclostrobin 2.7%, triazole fungicides 2.7%, soybean lecithin 10%, hydrogenated castor oil derivatives 8%, fumed silica 3% , gallic acid 3%, phytic acid 1.6%, secondary doped polyaniline nanomaterials 1.5%, shell powder 25%. This embodiment gained product specification is as table 1:

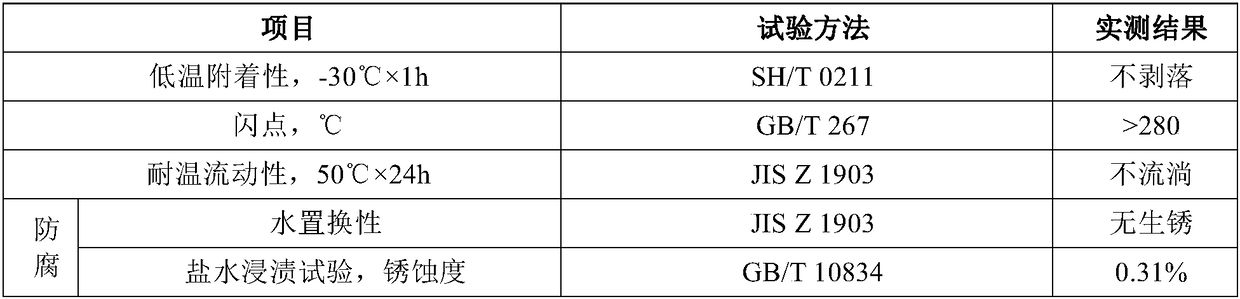

[0038] Table 1 embodiment 1 product specification

[0039]

[0040]

Embodiment 2

[0042] Aiming at metal structures that are susceptible to corrosion damage mainly by crevice corrosion, fretting corrosion, and stress corrosion, such as steel structure assemblies such as bolt joints, steel structures combined with seams, and welding points of load-bearing structures, the present invention proposes the following anti-corrosion solutions Program:

[0043] A semi-solid anti-corrosion paste for steel structure, its composition is calculated by percentage: sunflower oil 19%, hydroxyl-terminated polybutadiene 16.8%, pharmaceutical grade vaseline 4.2%, antioxidant 1010 0.75%, Antioxidant BHT 0.25%, flufenapyramide 2.5%, pyraclostrobin 2.5%, triazole fungicides 2.5%, soybean lecithin 9.5%, hydrogenated castor oil derivatives 7.5%, fumed silica 4 %, red iron oxide 1%, gallic acid 3.6%, phytic acid 1.7%, secondary doped polyaniline nanomaterials 1.7%, shell powder 22.5%. This embodiment gained product specification is as table 2:

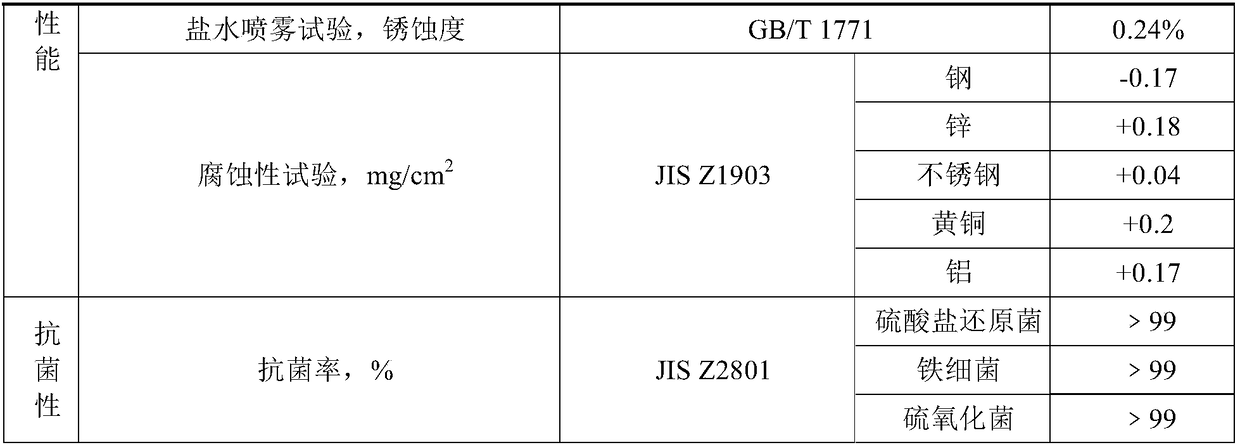

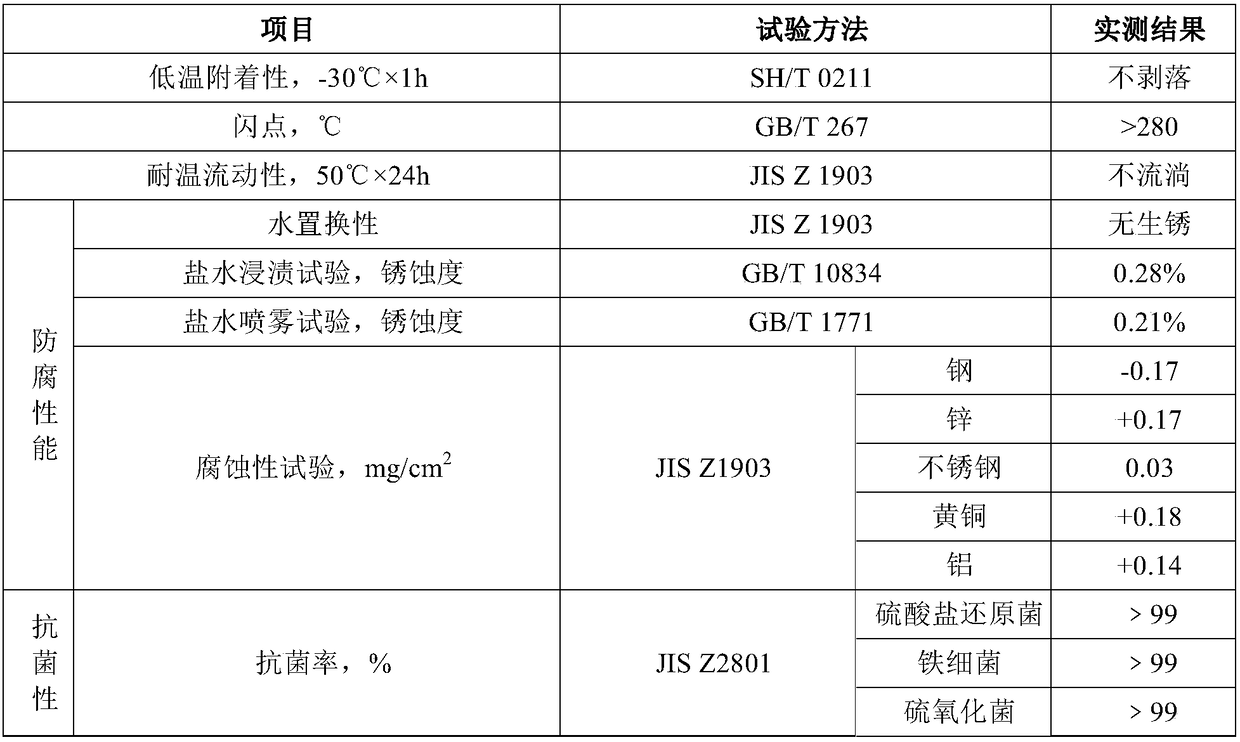

[0044] Table 2 embodiment 2 produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com