Marine shellfish soil conditioner and production method thereof

A soil conditioner and marine technology, applied in the field of soil conditioning, can solve problems such as imbalance of nutrients, surface soil compaction, and low mobility of lime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

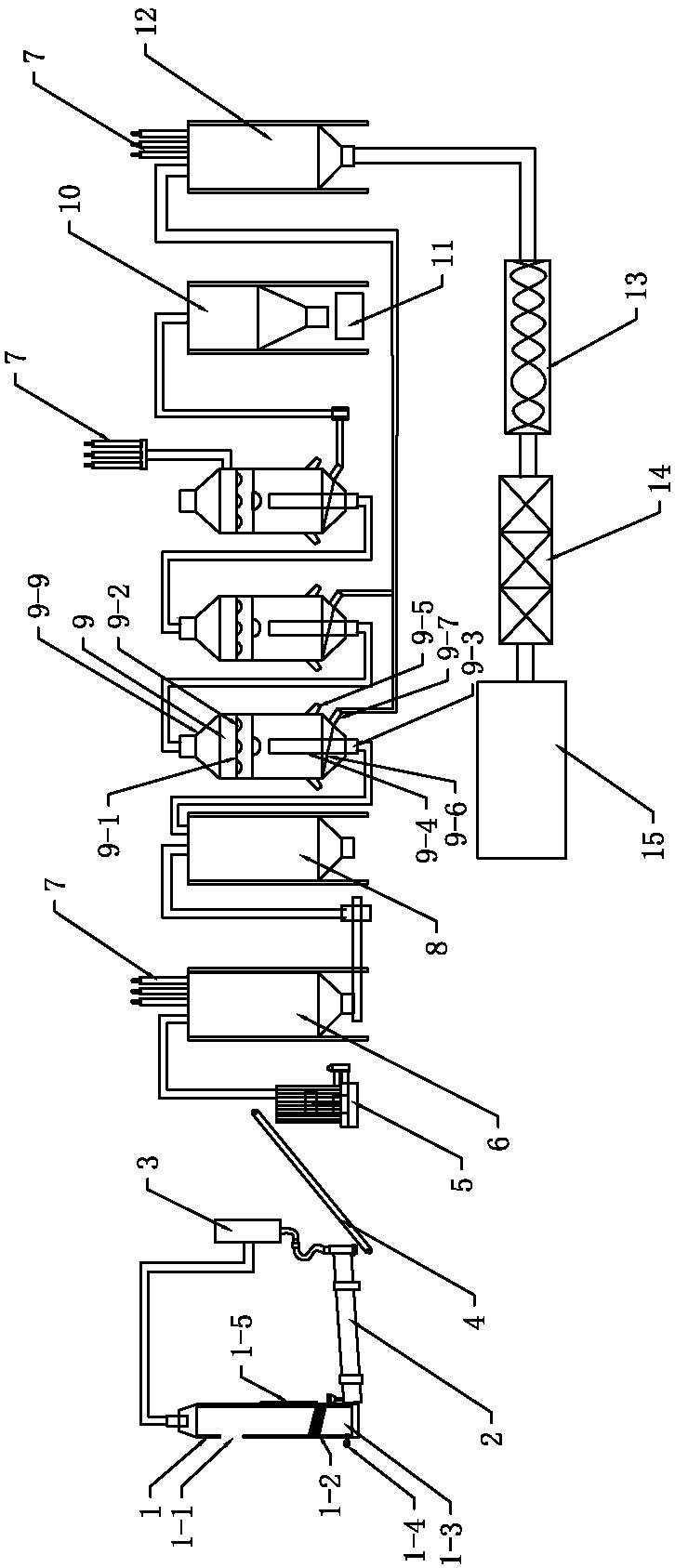

Method used

Image

Examples

Embodiment 1

[0045] The marine shellfish soil conditioner of the present embodiment comprises the raw material of following parts by weight:

[0046] 75 servings of oyster shell powder

[0047] Bacillus subtilis 0.1 parts

[0048] 12 parts bamboo vinegar

[0049] Chitin 0.1 parts

[0050] Molasses 8 parts.

[0051] The preparation method of marine shellfish soil conditioner comprises the following steps:

[0052] (1) Preparation of oyster shell powder

[0053] 1.1 Put the marine shells into the calcination furnace for high-temperature calcination, the calcination temperature is 2500°C, and calcine for 4 hours;

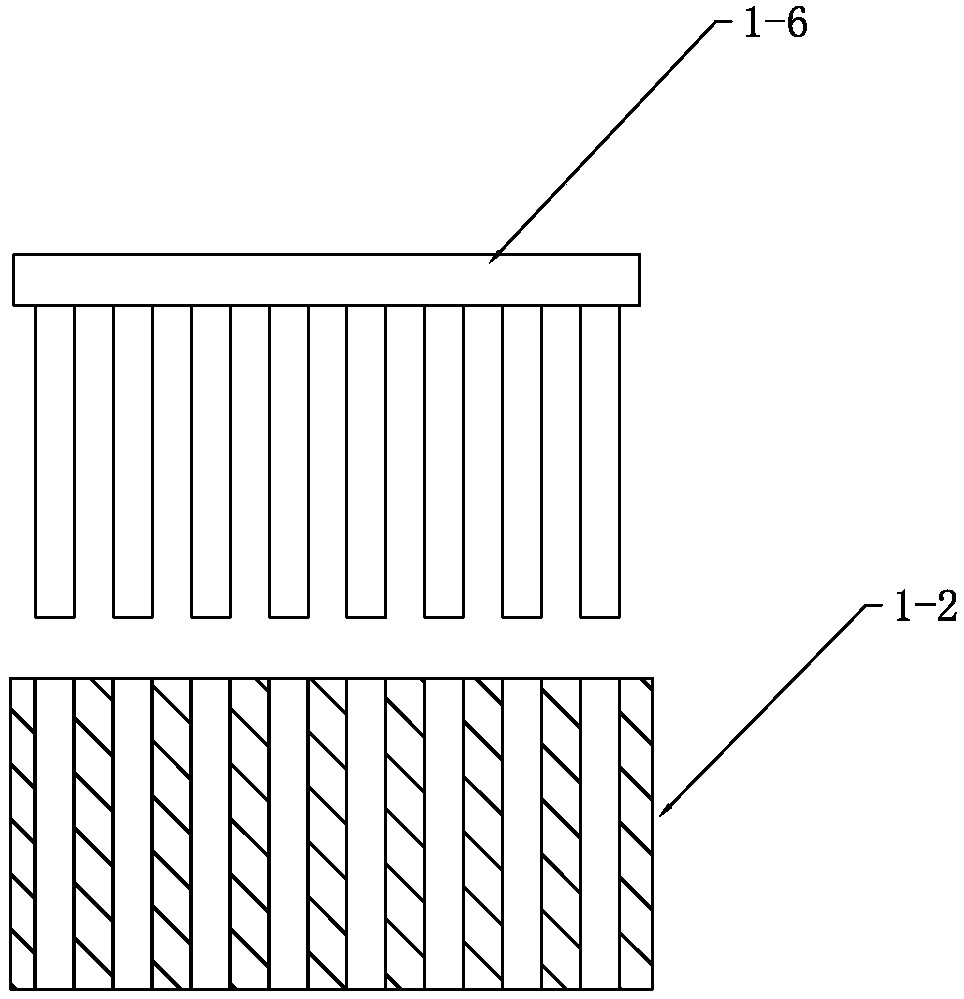

[0054]1.2 Transport the calcined marine shells to the rotary kiln for cooling; the rotary kiln

[0055] 1.3 Pulverize the cooled oyster shells to obtain oyster shell powder of 100 mesh to -300 mesh;

[0056] 1.4 The oyster shell powder is air-selected to obtain shell powder with uniform particles;

[0057] (2) Prepare soil conditioner

[0058] 2.1 Mix the oyster shell powd...

Embodiment 2

[0068] The main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

[0069] The marine shellfish soil conditioner includes the following raw materials in parts by weight:

[0070] Oyster shell powder 85 parts

[0071] Bacillus subtilis 0.3 part

[0072] 15 parts of bamboo vinegar

[0073] Chitin 0.3 parts

[0074] Molasses 12 parts.

[0075] In the preparation method of marine shellfish soil conditioner,

[0076] 1.1 Calcining the oysters at a temperature of 1500°C for 5 hours;

[0077] 1.2 Cool to a temperature of 80°C;

[0078] 2.2 The fermentation tank was reacted for 70 hours;

[0079] 2.3 Dry the fermented material to a dryness of 85% to obtain a soil conditioner.

[0080] Table 2 The soil conditioner of this embodiment is applied to the experimental data of alkaline soil

[0081]

Embodiment 3

[0083] The main technical solution of this embodiment is basically the same as that of Embodiment 1 or Embodiment 2. The features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here.

[0084] The marine shellfish soil conditioner includes the following raw materials in parts by weight:

[0085] Oyster shell powder 80 parts

[0086] Bacillus subtilis 0.2 parts

[0087] 13 parts bamboo vinegar

[0088] Chitin 0.2 parts

[0089] Molasses 10 parts.

[0090] 1.1 Calcining oyster shells at a temperature of 2000°C for 4.5 hours;

[0091] 1.2 Transport the marine shells calcined in step 1.1 to a rotary kiln to cool to a temperature of 96°C;

[0092] 2.2 The fermentation tank was reacted for 60 hours;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com