Coal powder hydropyrolysis and gasification integrated system and treatment method thereof

A technology of hydropyrolysis and pulverized coal, which is applied in the field of coal chemical industry, can solve the problems of low heat utilization rate and complicated process, and achieve the effect of increasing utilization rate, improving yield and oil quality, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

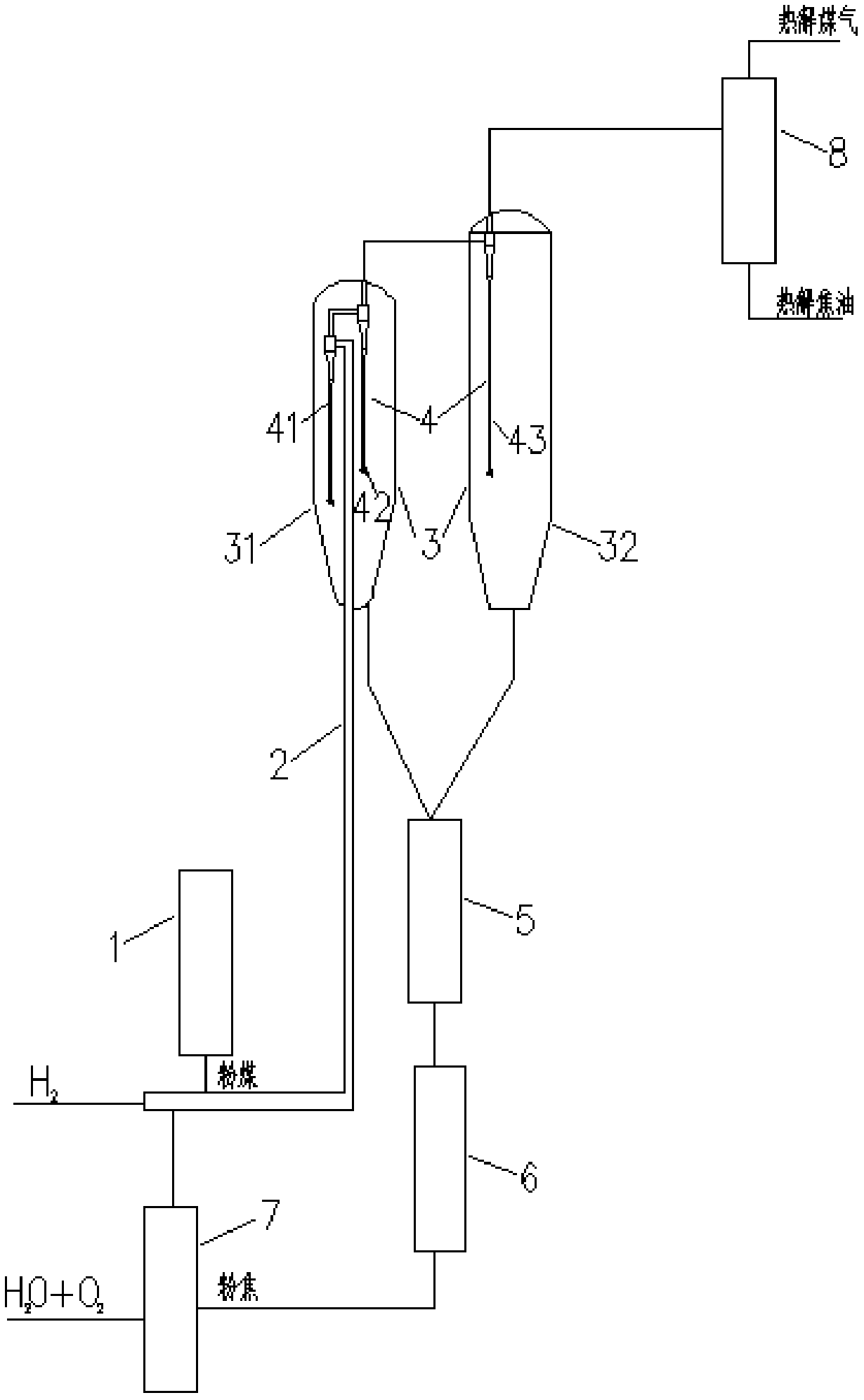

[0055] This embodiment provides an integrated system of pulverized coal hydropyrolysis and gasification, and its connection schematic diagram is as follows figure 1 As shown, the system includes a feed unit, a reaction unit and a separation unit, the reaction unit includes a riser reactor 2 and a gasifier 7, and the separation unit includes a settler 3 and an oil-gas separation device 8; wherein, the The outlet of the riser reactor 2 is connected to the inlet of the settler 3, the bottom outlet of the settler 3 is connected to the inlet of the gasifier 7, and the gas outlet of the gasifier 7 is connected to the inlet of the riser reactor 2. The top outlet of the settler 3 is connected with the inlet of the oil-gas separation device 8 .

[0056] Wherein, the settler 3 comprises a primary settler 31 and a secondary settler 32; the outlet of the riser reactor 2 is connected to the inlet of the primary settler 31, and the top outlet of the primary settler 31 is connected to the T...

Embodiment 2

[0061] This embodiment provides a pulverized coal hydropyrolysis and gasification integrated system, the system includes a feed unit, a reaction unit and a separation unit, the reaction unit includes a riser reactor 2 and a gasifier 7, the The separation unit includes a settler 3 and an oil-gas separation device 8; wherein, the outlet of the riser reactor 2 is connected to the inlet of the settler 3, and the bottom outlet of the settler 3 is connected to the inlet of the gasifier 7, so The gas outlet of the gasifier 7 is connected with the inlet of the riser reactor 2, and the top outlet of the settler 3 is connected with the inlet of the oil-gas separation device 8.

[0062] Wherein, the settler 3 has one stage, and its built-in cyclone separator 4 is one, the outlet of the riser reactor 2 is connected with the inlet of the cyclone separator 4, and the top outlet of the cyclone separator 4 is separated from the oil and gas The inlet of device 8 is connected.

[0063] The fee...

Embodiment 3

[0066] This embodiment provides a method for integrating pulverized coal hydropyrolysis and gasification. The method is carried out using the system in Embodiment 1, and specifically includes the following steps:

[0067] (a) After mixing pulverized coal with a particle size of 0.4mm, syngas and hydrogen, a pyrolysis reaction occurs in the riser reactor 2. The reaction temperature is 650°C, the reaction pressure is 6.0MPa, and the reaction time is 5s. solution product;

[0068] (b) The pyrolysis product obtained in step (a) is subjected to gas-solid separation in the primary settler 31 and the secondary settler 32 respectively, and the gas phase product of the gained is carried out oil-gas separation in the oil-gas separation device 8 to obtain pyrolysis tar and pyrolysis gas;

[0069] (c) The powdered coke obtained in the gas-solid separation in step (b) is first cooled in the powdered coke cooler 5, and the cooling treatment temperature is 300°C, and then enters the gasifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com