Preparation method of long-acting water-based metal rust inhibitor

A metal rust inhibitor, water-based technology, applied in the direction of metal material coating technology, can solve problems such as aircraft parts and auto parts failure, and achieve good lubricity, remarkable effect, and good environmental protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

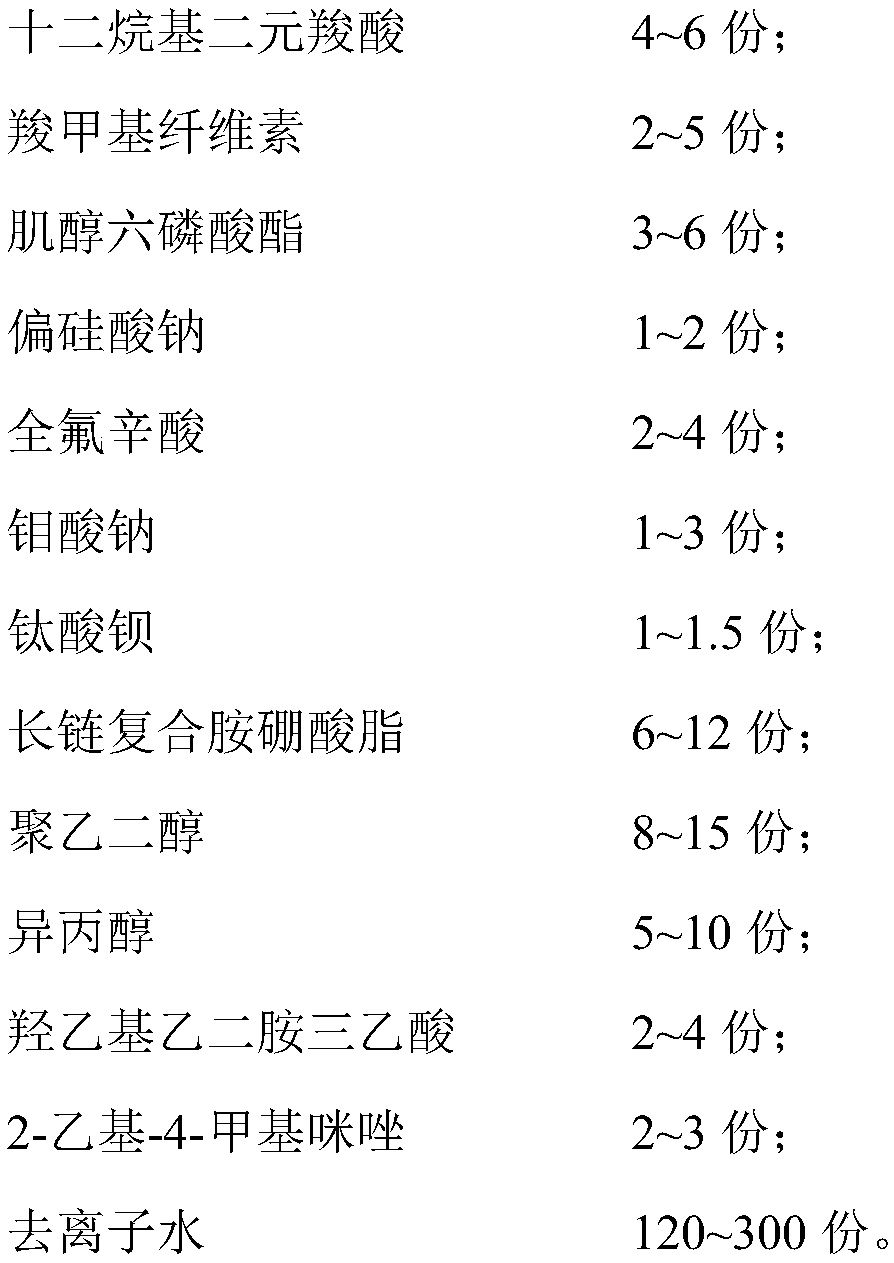

[0028] The long-acting water-based antirust agent provided in this embodiment is prepared from the following raw materials in parts by weight:

[0029]

[0030] Wherein, the preparation method of the long-chain complex amine borate ester is: 12 mass parts of boric acid, 12 mass parts of triethanolamine, 5 mass parts of tetraethylenepentamine, 3 mass parts of dodecylethyleneamine, 6 mass parts Add 80 parts by mass of polyvinyl alcohol to 80 parts by mass of anhydrous DMSO to obtain a mixed solution, raise the temperature of the mixed solution to 130°C, reflux for 4 hours, distill off DMSO and a small amount of water under reduced pressure, and then add 60 parts by mass of tetrahydrofuran Separating unreacted triethanolamine, tetraethylenepentamine, and dodecylethyleneamine, removing residual tetrahydrofuran, and vacuum drying to obtain a colorless viscous long-chain complex borate ester.

[0031] The preparation method of the above-mentioned long-acting water-based antirust ...

Embodiment 2

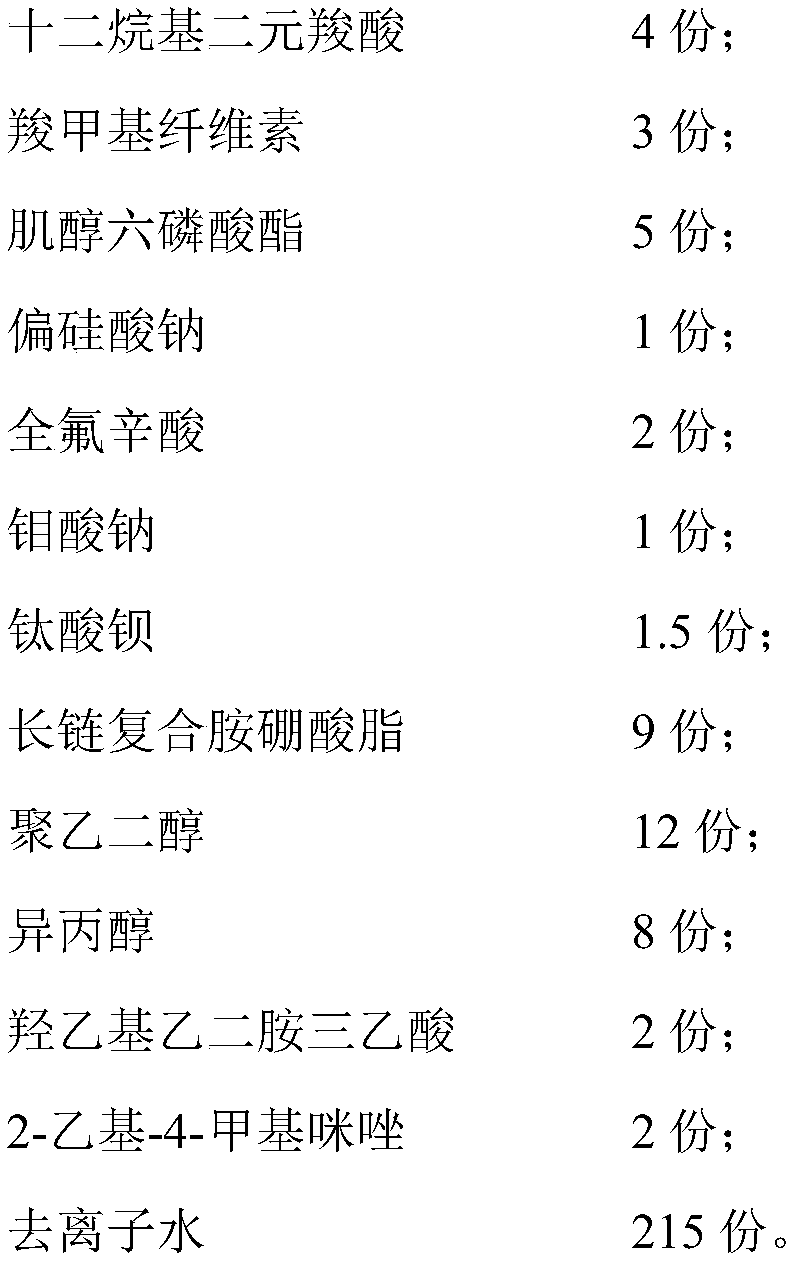

[0036] The long-acting water-based antirust agent provided in this embodiment is prepared from the following raw materials in parts by weight:

[0037]

[0038] Wherein, the preparation method of the long-chain compound amine borate ester is: 10 mass parts of boric acid, 12 mass parts of triethanolamine, 7 mass parts of tetraethylenepentamine, 4 mass parts of dodecylethyleneamine, 4 mass parts Add 100 parts by mass of polyvinyl alcohol to 100 parts by mass of anhydrous DMSO to obtain a mixed solution, raise the temperature of the mixed solution to 120°C, reflux for 6 hours, distill off DMSO and a small amount of water under reduced pressure, and then add 50 parts by mass of tetrahydrofuran Separating unreacted triethanolamine, tetraethylenepentamine, and dodecylethyleneamine, removing residual tetrahydrofuran, and vacuum drying to obtain a colorless viscous long-chain complex borate ester.

[0039] The preparation method of the above-mentioned long-acting water-based antiru...

Embodiment 3

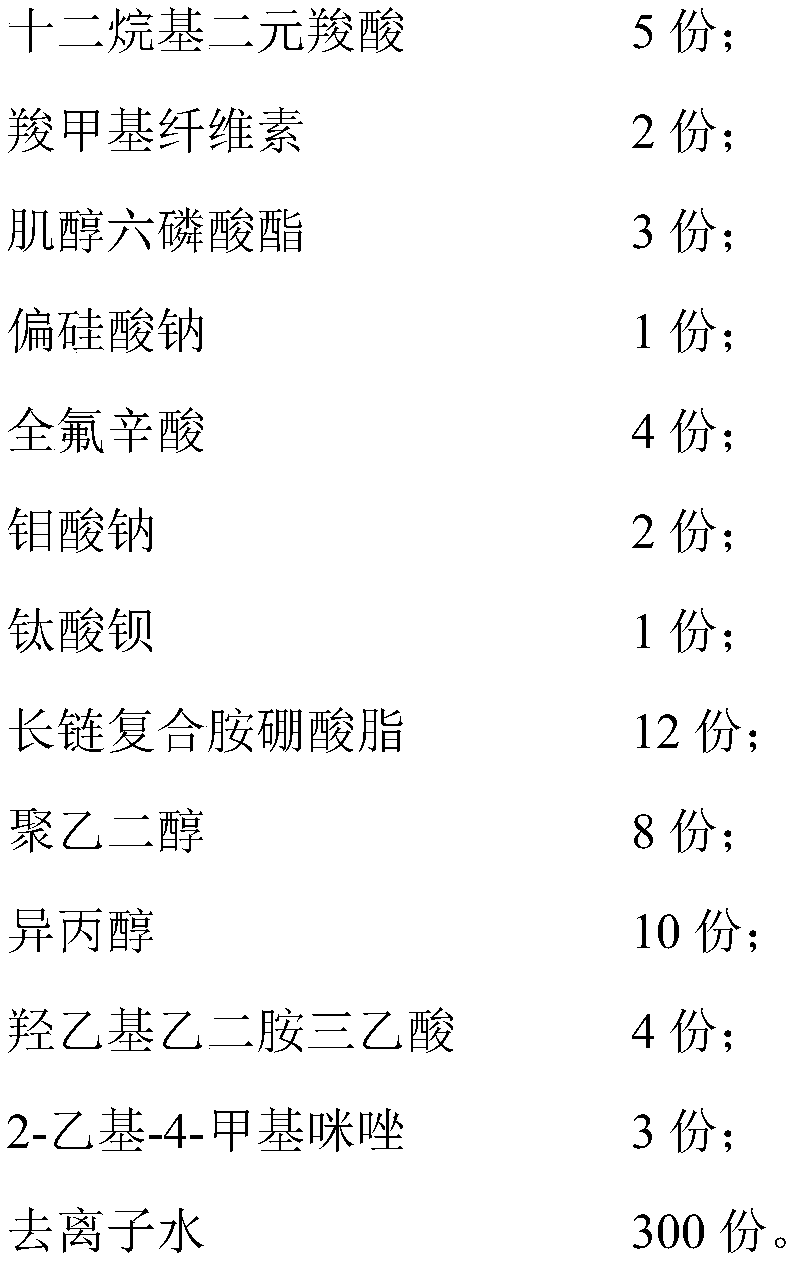

[0044] The long-acting water-based antirust agent provided in this embodiment is prepared from the following raw materials in parts by weight:

[0045]

[0046] Wherein, the preparation method of the long-chain complex amine borate ester is: 15 parts by mass of boric acid, 15 parts by mass of triethanolamine, 8 parts by mass of tetraethylenepentamine, 4 parts by mass of dodecylethyleneamine, 8 parts by mass of Add 50 parts by mass of polyvinyl alcohol to 50 parts by mass of anhydrous DMSO to obtain a mixed solution, raise the temperature of the mixed solution to 110°C, reflux for 5 hours, distill off DMSO and a small amount of water under reduced pressure, and then add 80 parts by mass of tetrahydrofuran Separating unreacted triethanolamine, tetraethylenepentamine, and dodecylethyleneamine, removing residual tetrahydrofuran, and vacuum drying to obtain a colorless viscous long-chain complex borate ester.

[0047] The preparation method of the above-mentioned long-acting wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com