Preparation method and application of regenerated cellulose fibers with antibacterial anti-acarien and moldproof function

A technology of regenerated cellulose and denatured cellulose, which is applied in the directions of single-component cellulose rayon, chemical characteristics of fibers, preparation of spinning solutions, etc. and other problems, to achieve the effect of high wet modulus, reliable and simple operation of the production process, and small coefficient of variation of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

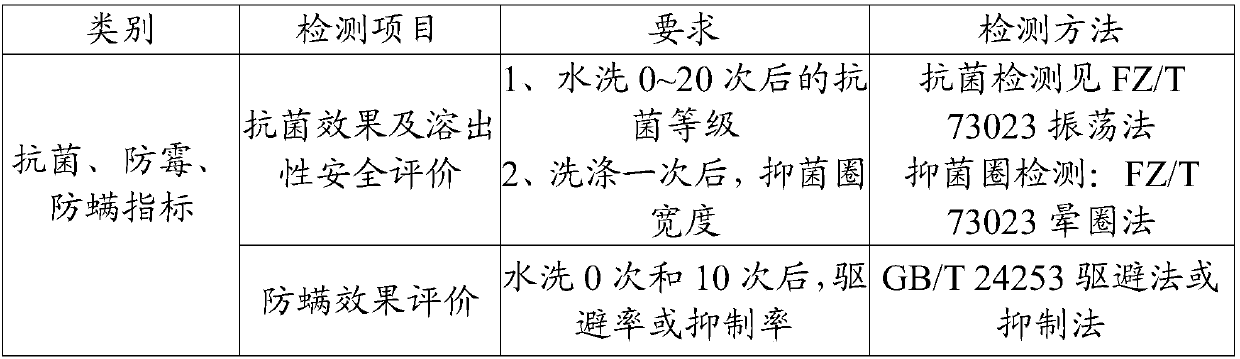

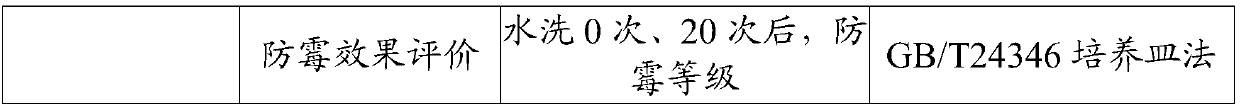

Image

Examples

Embodiment 1

[0048] A preparation method of 1.11dtex×38mm multifunctional regenerated cellulose fiber with plant-based antibacterial, anti-mite and anti-mildew functions, including the following steps:

[0049] 1. Preparation steps of composite slurry

[0050] 1) Mix, pulverize and grind the Stemone extract and Coptis extract to obtain the mixed powder of the two. The mass ratio of Stemone and Coptis extract in the mixed powder is 1:0.5, and the powder particle size D90=1.279μm ,spare.

[0051] 2) Blend the above-prepared mixed powder and Litsea cubeba essential oil evenly to coat the surface of the powder with a layer of Litsea cubeba essential oil to prepare an oily mixed powder slurry, wherein the quality of the mixed powder and Litsea cubeba essential oil The ratio is 5:1.

[0052] 3) Add methyl methacrylate to the oily powder slurry and stir evenly, then add benzoyl peroxide and stir evenly to obtain a composite oil phase. Among them, the mass ratio of the oily mixed powder slurry, methyl m...

Embodiment 2

[0065] A preparation method of 1.33dtex×38mm multifunctional regenerated cellulose fiber with plant-based antibacterial, anti-mite and anti-mildew functions, including the following steps:

[0066] 1. Preparation steps of composite slurry

[0067] 1) Mix, pulverize and grind the extract of Stemone and Coptis extract to obtain a mixed powder of the two. The mass ratio of Stemone and Coptis extract in the mixed powder is 1:0.75, and the particle size of the powder is D90=1.347μm. ,spare.

[0068] 2) Blend the above-prepared mixed powder and Litsea cubeba essential oil evenly to coat the surface of the powder with a layer of Litsea cubeba essential oil to prepare an oily mixed powder slurry, wherein the quality of the mixed powder and Litsea cubeba essential oil The ratio is 6:1.

[0069] 3) Add methyl methacrylate to the oily powder slurry and stir evenly, then add benzoyl peroxide and stir evenly to obtain a composite oil phase. Among them, the mass ratio of oily mixed powder slurry,...

Embodiment 3

[0082] A preparation method of a 1.56dtex×38mm multifunctional regenerated cellulose fiber with plant-based antibacterial, anti-mite and anti-mold functions, including the following steps:

[0083] 1. Preparation steps of composite slurry

[0084] 1) Mix, pulverize and grind the extract of Stemone and Coptis extract to obtain a mixed powder of the two. The mass ratio of Stemone and Coptis extract in the mixed powder is 1:1, and the particle size of the powder is D90=1.431μm. ,spare.

[0085] 2) Blend the above-prepared mixed powder and Litsea cubeba essential oil evenly to coat the surface of the powder with a layer of Litsea cubeba essential oil to prepare an oily mixed powder slurry, wherein the quality of the mixed powder and Litsea cubeba essential oil The ratio is 7:1.

[0086] 3) Add methyl methacrylate to the oily powder slurry and stir evenly, then add benzoyl peroxide and stir evenly to obtain a composite oil phase. Among them, the mass ratio of oily mixed powder slurry, me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com