Preparation method of superconductive Josephson junction

A superconducting and substrate technology, which is used in the manufacture/processing of superconducting devices, devices containing a node of different materials, superconducting devices, etc. , difficult to control and other problems, to avoid the preparation process of the suspension glue, reduce the difficulty, and achieve the effect of high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047]The preparation method of the superconducting Josephson junction of the present embodiment, its steps are:

[0048] 1) Substrate pretreatment

[0049] A material with a resistivity > 10000 ohm*cm is selected as the substrate; a silicon wafer with a high resistance value is preferred.

[0050] The substrate is cleaned, and the cleaning method may be ultrasonic cleaning. Then transfer the substrate to a container containing isopropanol (IPA) for immersion, then transfer the substrate to a container containing deionized water (DI) for immersion, and finally take out the substrate and dry it with inert gas. sheet, to obtain a clean substrate;

[0051] 2) Electron beam exposure

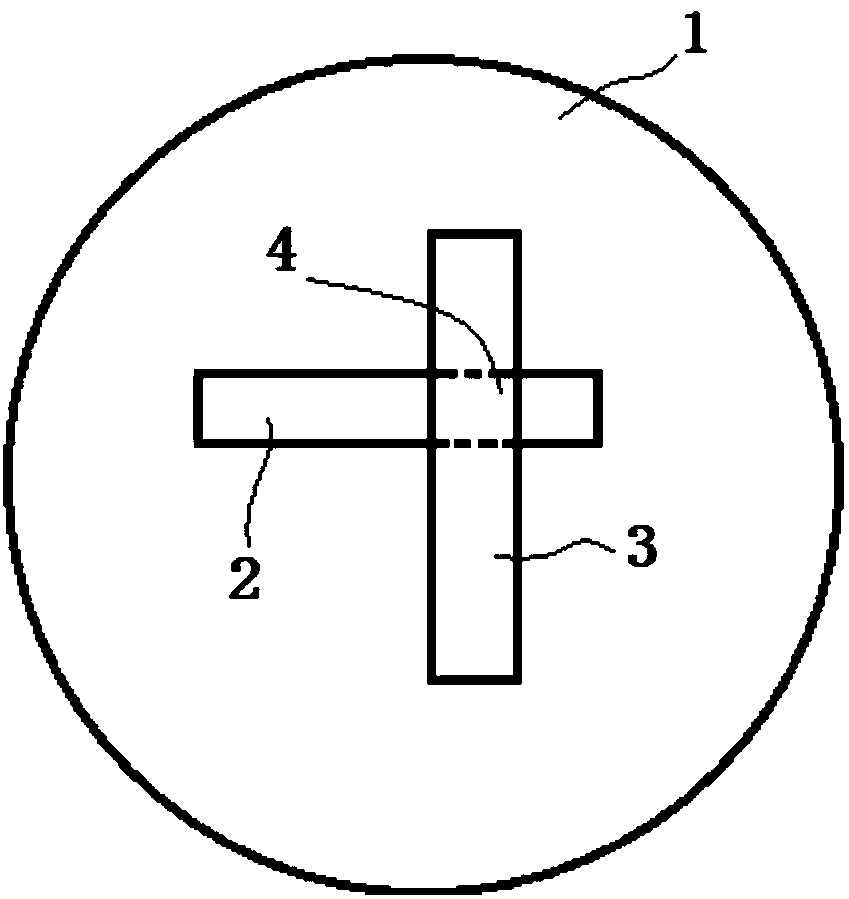

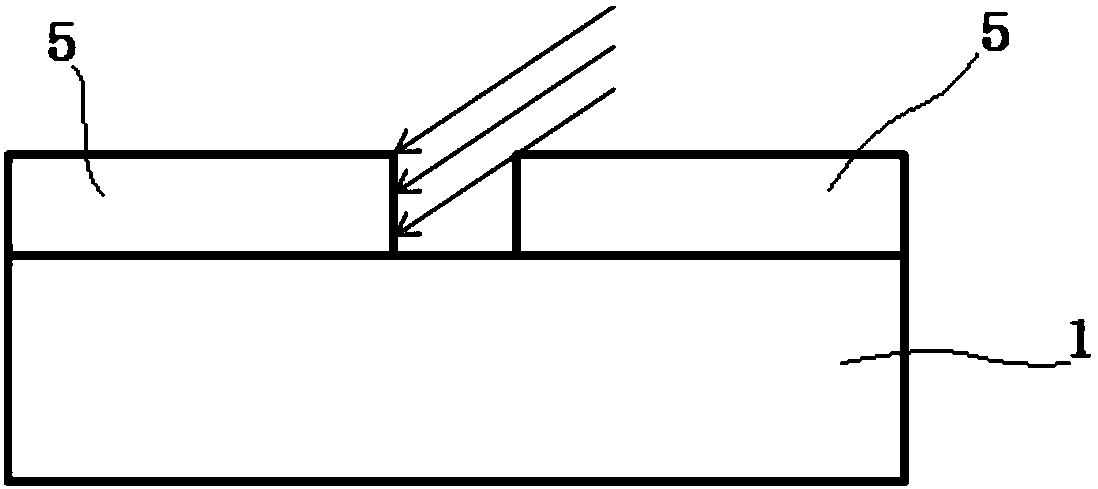

[0052] Coating electron beam glue 5 on the substrate, using electron beam exposure equipment to expose two regions A region and B region on the substrate, A region 2 and B region 3 have intersecting region C region 4; according to different electron beam glue, baking Select the appropriate exposu...

Embodiment 1

[0061] The method for preparing superconducting Josephson junction in this embodiment is as follows:

[0062] 1) Substrate pretreatment, clean the substrate:

[0063] Put a high-resistance silicon wafer (with a resistance value of 10050 ohm*cm) in a beaker filled with 1-methyl-2-pyrrolidone (NMP) solution and vibrate ultrasonically for 3 minutes, then transfer the substrate to a beaker filled with isopropanol (IPA ) solution in a beaker for 3 minutes, and finally put the substrate in deionized water (DI) solution and ultrasonically vibrate for 3 minutes. 100%, making the substrate clean enough for the next step. Here, the ultrasonic time can be controlled at more than 3 minutes to achieve the technical purpose, preferably 3 minutes to 5 minutes in order to improve the experimental efficiency.

[0064] 2) Electron beam exposure

[0065] Put a single layer of MMA glue on the cleaned silicon wafer and a layer of PMMA950A4 glue evenly, and the thickness of the electron beam glu...

Embodiment 2

[0076] The method for preparing superconducting Josephson junction in this embodiment is as follows:

[0077] 1) Substrate pretreatment: the substrate is made of a high-resistance silicon chip (10000 ohms*cm is used in this embodiment), and the high-resistance silicon chip is first placed in a beaker filled with 1-methyl-2-pyrrolidone (NMP) solution and ultrasonically Vibrate for 4min, then transfer the substrate to a beaker filled with isopropanol (IPA) solution and ultrasonically vibrate for 4min, finally put the substrate in deionized water (DI) solution Clamp the sample with tweezers and blow out the sample with a nitrogen chamber, and the ultrasonic power is 100%, so that the substrate can reach a clean level suitable for the next step;

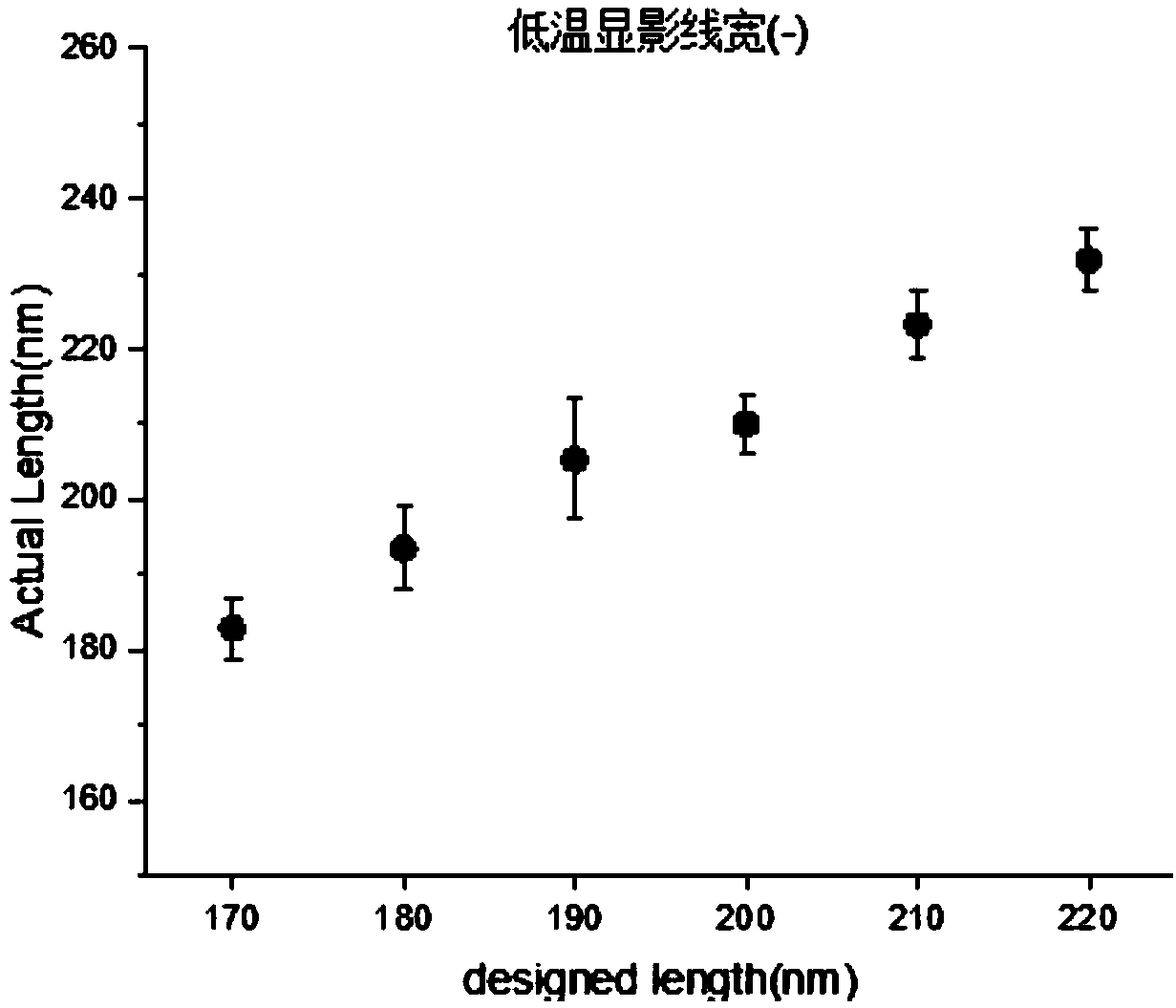

[0078] 2) The preparation stage of the superconducting Josephson junction: the cleaned silicon wafer is evenly coated with a single layer of MMA glue and a layer of PMMA950A4 glue. 3000r / min, time 40s, bake at 150°C for 95 seconds; PMMA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com