Preparation method of high-activity lactobacillus paracasei N1115 ready-to-eat probiotic powder

A technology of para-cheese and Lactobacillus, which is applied in the food field, can solve the problems of not providing a preparation method, and achieve the effects of increasing the yield, increasing the concentration of bacteria, and reducing blood sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0036] Embodiment 1-6 The preparation method of highly active Lactobacillus paracasei N1115 ready-to-eat probiotic powder

[0037] Embodiment 1-6 is respectively a kind of preparation method of highly active Lactobacillus paracasei N1115 ready-to-eat probiotic powder, and they carry out according to the following steps:

[0038] (1) Bacteria activation and proliferation culture

[0039] Inoculate Lactobacillus paracasei N1115 into the MRS liquid medium for activation;

[0040] The activated bacteria were inoculated in high-density medium (containing 20g / L glucose, 20g / L yeast powder, 0.09mol / L buffer salt, 50mg / L MnSO4•5H2O) for proliferation and culture, and the number of viable bacteria was detected , until the number of live bacteria reaches 106-108CFU / ml, the bacterial solution A is obtained;

[0041] (2) Collect bacteria

[0042] Centrifuge the bacterial solution A at a low temperature and high speed at 4°C and 12000 rpm, discard the supernatant to obtain the bacterial...

Embodiment 7

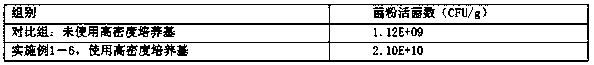

[0054] Example 7 The comparative test of the beneficial effects of using high-density medium in the preparation method of the highly active Lactobacillus paracasei N1115 instant probiotic powder of Examples 1-6

[0055] In this embodiment, by designing a comparative test, the use of a high-density culture medium during the activation and proliferation of the strains has been studied on the beneficial effects that can be produced on the number of live bacteria in the prepared bacterial powder. The specific test results are as follows:

[0056]

[0057] It can be seen that the use of high-density medium in the activation and proliferation of strains can increase the concentration of bacteria in the sludge, thereby increasing the yield of bacteria powder.

Embodiment 8

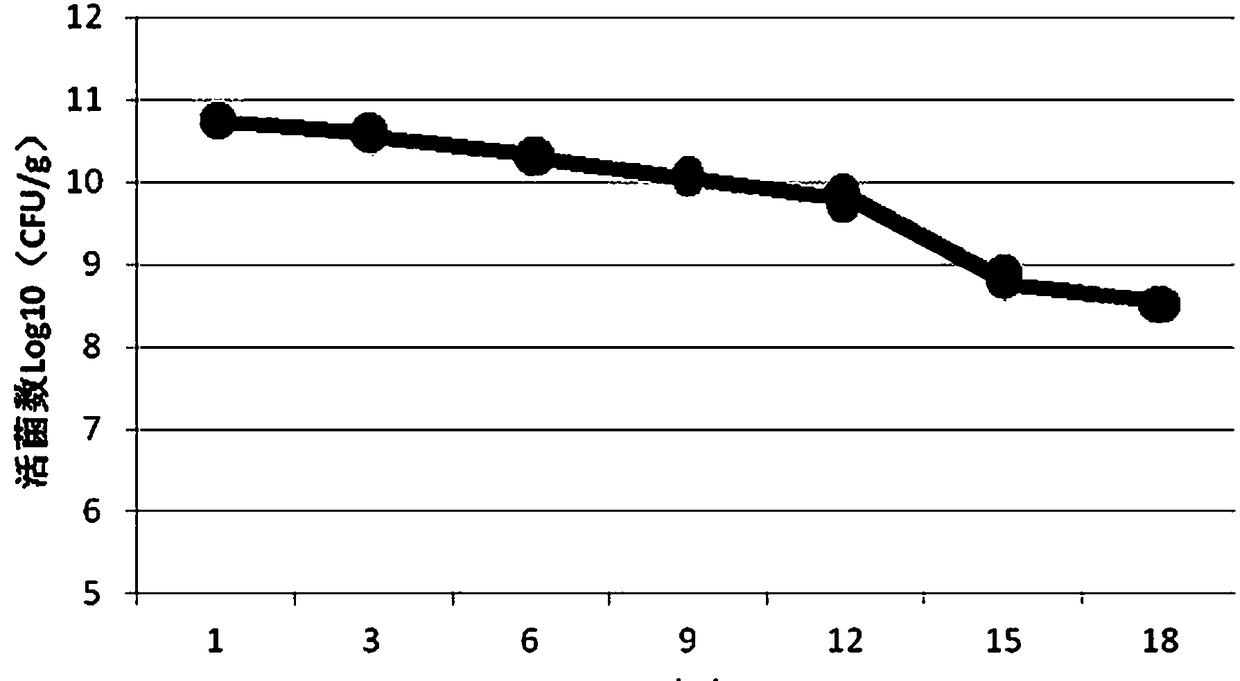

[0058] Example 8 Detection test on the number of viable bacteria within the shelf life of the highly active Lactobacillus paracasei N1115 ready-to-eat probiotic powder produced in Examples 1-6

[0059] In this embodiment, the number of live bacteria of various high-activity Lactobacillus paracasei N1115 ready-to-eat probiotic powders prepared in Examples 1-6 was tracked and detected within 18 months. The test results refer to figure 1 , show that the highly active Lactobacillus paracasei N1115 ready-to-eat probiotic powder provided by the present invention is within the shelf life of 18 months, and the number of live bacteria is gradually declining, but still remains at 10 when 18 months expire. 8 More than cfu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com