Catalysts for preparing gamma-valerolactone as well as preparation method and application of catalysts

A valerolactone and catalyst technology, applied in the field of ruthenium-based catalysts and their preparation, can solve problems such as poor recycling performance and inability to industrialize, achieve good dispersibility, improve economy, and overcome the effects of high loading of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

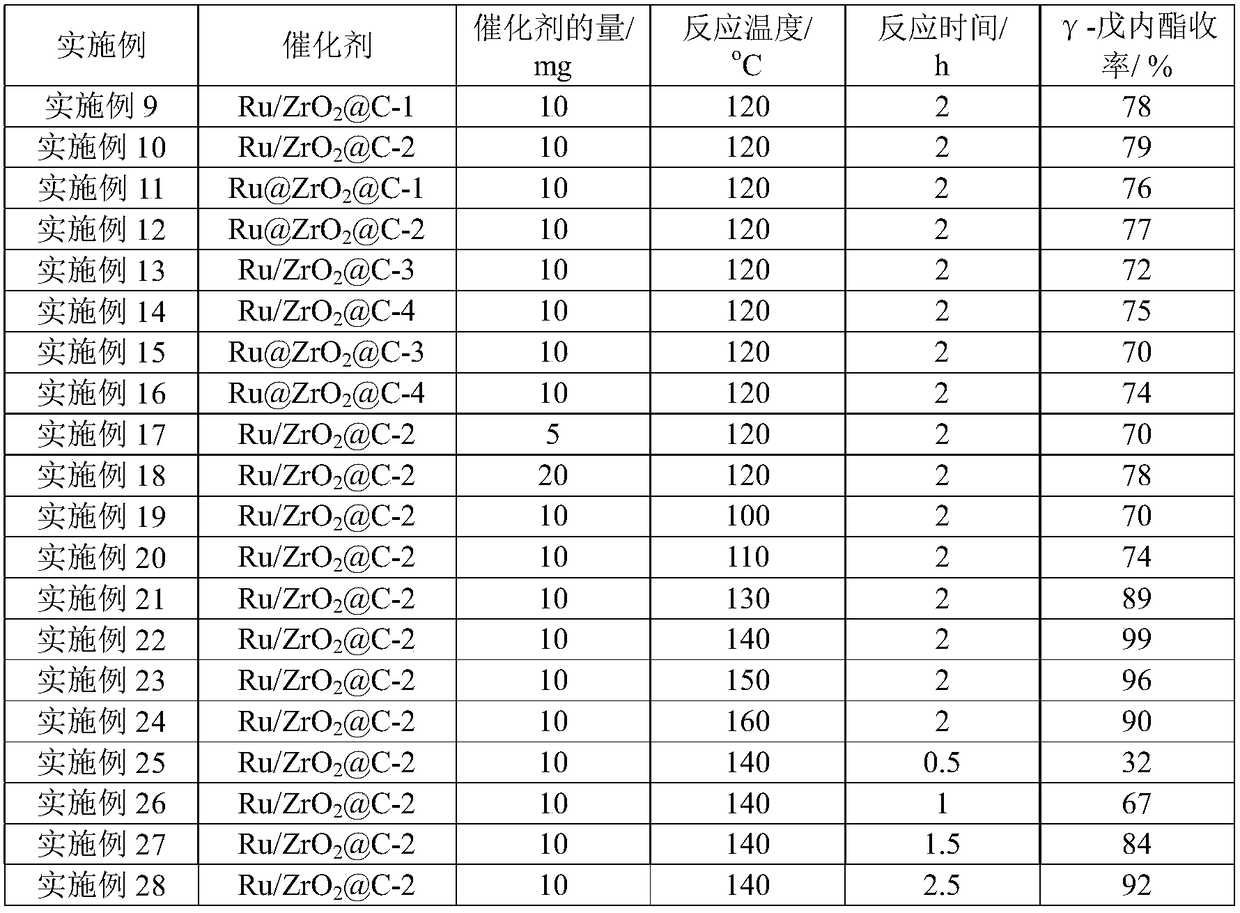

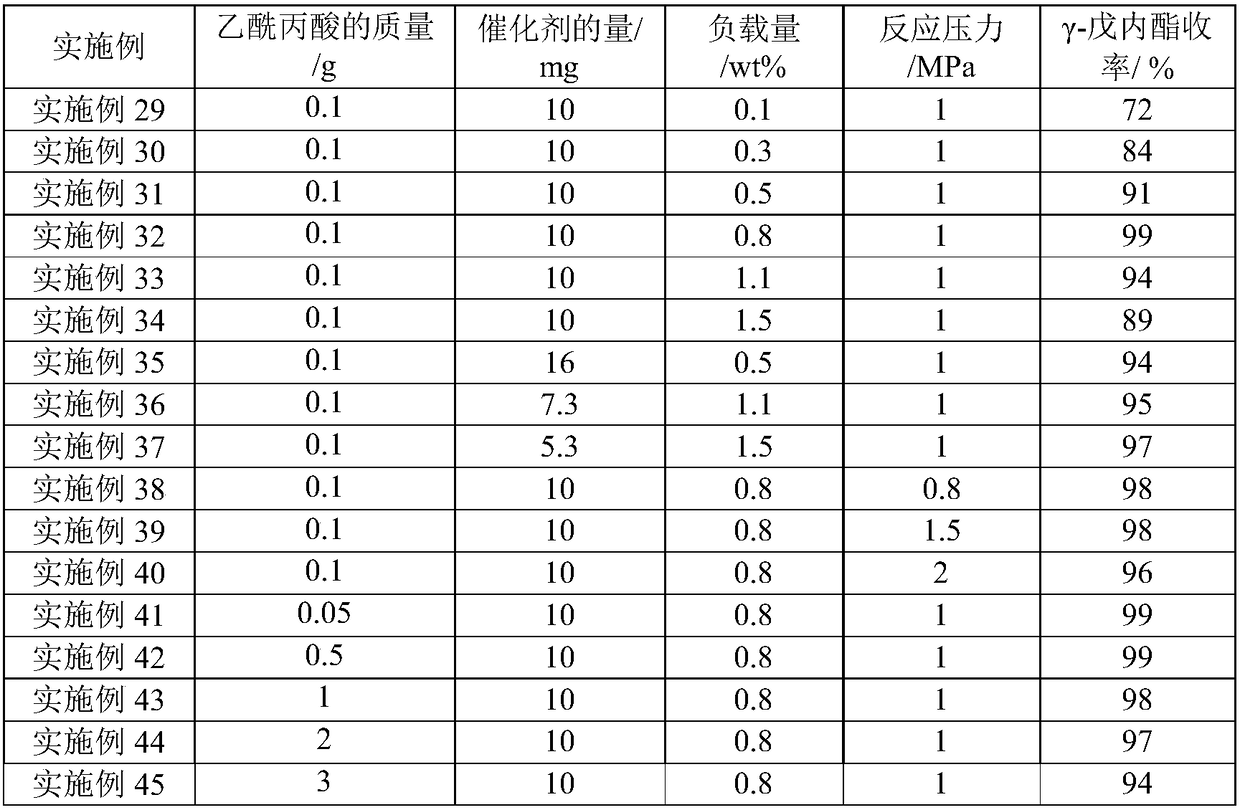

Examples

Embodiment Construction

[0017] The present invention will be described below with specific examples, but the protection scope of the present invention is not limited to these examples.

[0018] 1. Preparation of catalyst

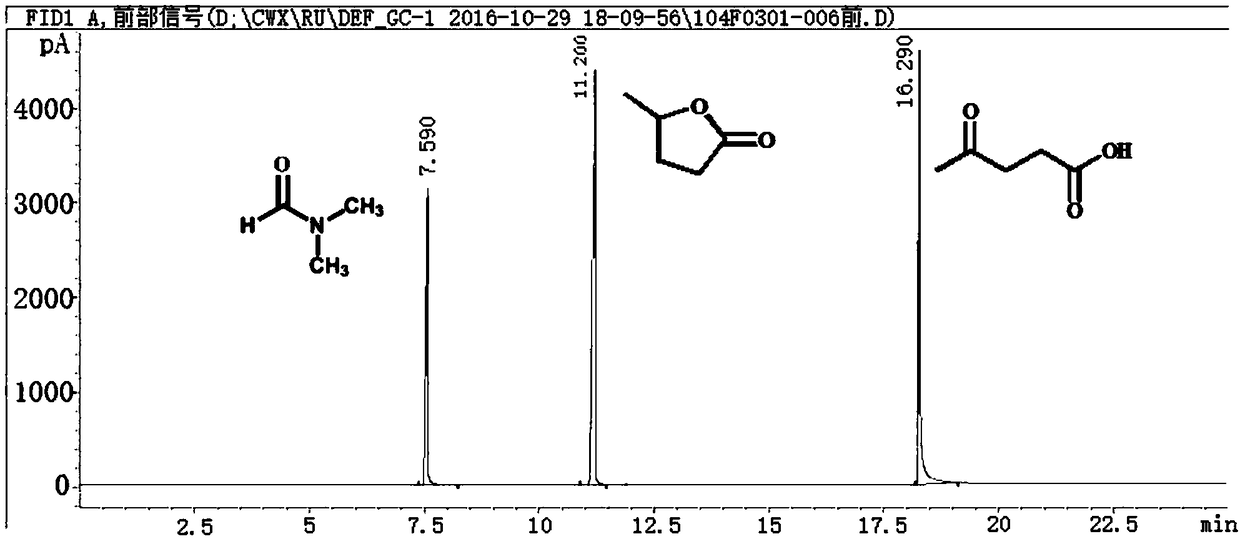

[0019] Weigh 0.28g of zirconium chloride and dissolve it in 40mL of DMF, add 0.232g of terephthalic acid to it, add a certain amount of glacial acetic acid and RuCl 3 The solution was sonicated for 30min and then transferred to a 100mL hydrothermal reaction kettle. The reaction kettle was placed in a programmed temperature-controlled oven, and the heating rate was set to 1°C / min, heated at 120°C for 24h, then slowly lowered to room temperature (24h), filtered, DMF washed three times, H 2 O washed three times and baked at 60 °C overnight to obtain UiO-66 or Ru@UiO-66 materials. Subsequently, the UiO-66 or Ru@UiO-66 sample was transferred to a tube furnace, raised to 600-800°C at a heating rate of 5°C / min, calcined under nitrogen atmosphere for 4-8 h, and ZrO was obtained after nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com