Lead-free red glue and preparation method thereof

A lead-free red glue, phenolic epoxy resin technology, used in adhesives, epoxy resin glue, adhesive types and other directions, can solve the problems of human body damage, low adhesion strength, low toughness, etc., to achieve safe and convenient use, improve Curing rate, scientific and reasonable effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

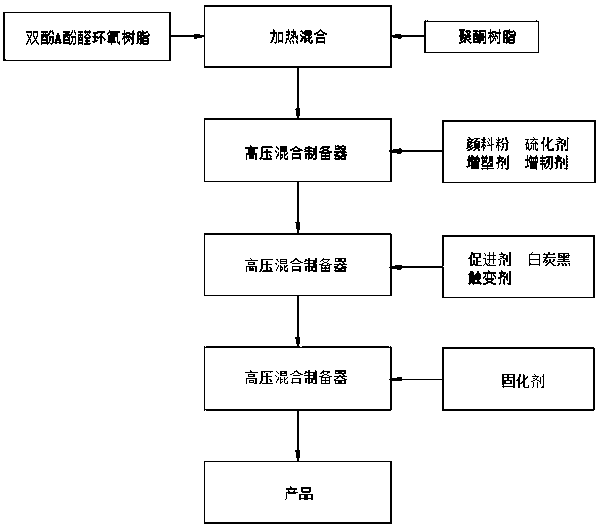

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A kind of lead-free red gum, prepared by the following components by weight: 45-53 parts of bisphenol A novolac epoxy resin, 15-29 parts of polyketone resin, 3-10 parts of curing agent, accelerator 9-11 parts of plasticizer, 42-53 parts of toughening agent, 1-4 parts of white carbon black, 16.5-30.5 parts of thixotropic agent, 3-27 parts of plasticizer, 6-15 parts of vulcanizing agent, 0.3-1.3 parts of pigment powder share.

[0020] Preferably, the bisphenol A novolac epoxy resin is prepared by mixing one or more of bisphenol A phenolic resin and epichlorohydrin.

[0021] Preferably, the plasticizer is made by mixing one or more of dioctyl phthalate, dibutyl phthalate, and dioctyl phthalate.

[0022] Preferably, the vulcanizing agent is zinc oxide and stearic acid used in combination, and the dosage is 2.5 parts and 1.8 parts respectively.

[0023] Preferably, the thixotropic agent is made by mixing one or more of fumed silica, organic bentonite, hydroge...

Embodiment 2

[0028] Embodiment 2: a kind of lead-free red glue, it is characterized in that: be prepared by the following components by weight: 47-50 parts of bisphenol A novolak epoxy resin, 20-25 parts of polyketone resin, 3.5-50 parts of curing agent 6.9 parts, 9.8-10.6 parts of accelerator, 45-48 parts of toughening agent, 1.6-3.5 parts of white carbon black, 18-29 parts of thixotropic agent, 6-23 parts of plasticizer, 6.5-13 parts of vulcanizing agent, pigment Powder 0.5-1.02 parts.

[0029] Preferably, the bisphenol A novolac epoxy resin is prepared by mixing one or more of bisphenol A phenolic resin and epichlorohydrin.

[0030] Preferably, the plasticizer is made by mixing one or more of dioctyl phthalate, dibutyl phthalate, and dioctyl phthalate.

[0031] Preferably, the vulcanizing agent is zinc oxide and stearic acid used in combination, and the dosage is 2.5 parts and 1.8 parts respectively.

[0032] Preferably, the thixotropic agent is made by mixing one or more of fumed sil...

Embodiment 3

[0037] Embodiment 3: a kind of lead-free red glue, it is characterized in that: be prepared by the following components by weight: 48 parts of bisphenol A novolac epoxy resin, 23 parts of polyketone resin, 5.3 parts of curing agent, 10.2 parts of accelerator parts, toughening agent 45.5 parts, white carbon black 2.3 parts, thixotropic agent 26.5 parts, plasticizer 15.6 parts, vulcanizing agent 9.7 parts, pigment powder 0.8 parts.

[0038] Preferably, the bisphenol A novolac epoxy resin is prepared by mixing one or more of bisphenol A phenolic resin and epichlorohydrin.

[0039]Preferably, the plasticizer is made by mixing one or more of dioctyl phthalate, dibutyl phthalate, and dioctyl phthalate.

[0040] Preferably, the vulcanizing agent is zinc oxide and stearic acid used in combination, and the dosage is 2.5 parts and 1.8 parts respectively.

[0041] Preferably, the thixotropic agent is made by mixing one or more of fumed silica, organic bentonite, hydrogenated castor oil,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com