Preparation method and application for oxygen-vacancy-enriched Bi2WO6/In2O3 heterojunction composite photocatalyst

An in2o3, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve the problems of unsatisfactory catalytic efficiency, high content of harmful substances, complex components, etc., to achieve green The effect of environmental protection treatment technology, simple operation and efficient treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1)In 2 o 3 Preparation of micron flowers:

[0030] InCl 3 4H 2 O was added to a beaker containing 60ml deionized water and stirred for 30min; 1.2g sodium lauryl sulfate was added to the mixed solution and continued to stir for 30min; then 0.42g urea was added to the mixed solution and stirred for 1h; subsequently, the above mixed solution was transferred Carry out constant temperature thermal reaction in a 120° C. reaction kettle for 12 hours; after the reaction is completed, the temperature is lowered to room temperature, the solid product is washed with deionized water and ethanol, and dried to obtain InOOH. Calcinate InOOH at 500°C for 2h with a heating rate of 2°C / min to remove H 2 O gets pale yellow In 2 o 3 micron flower.

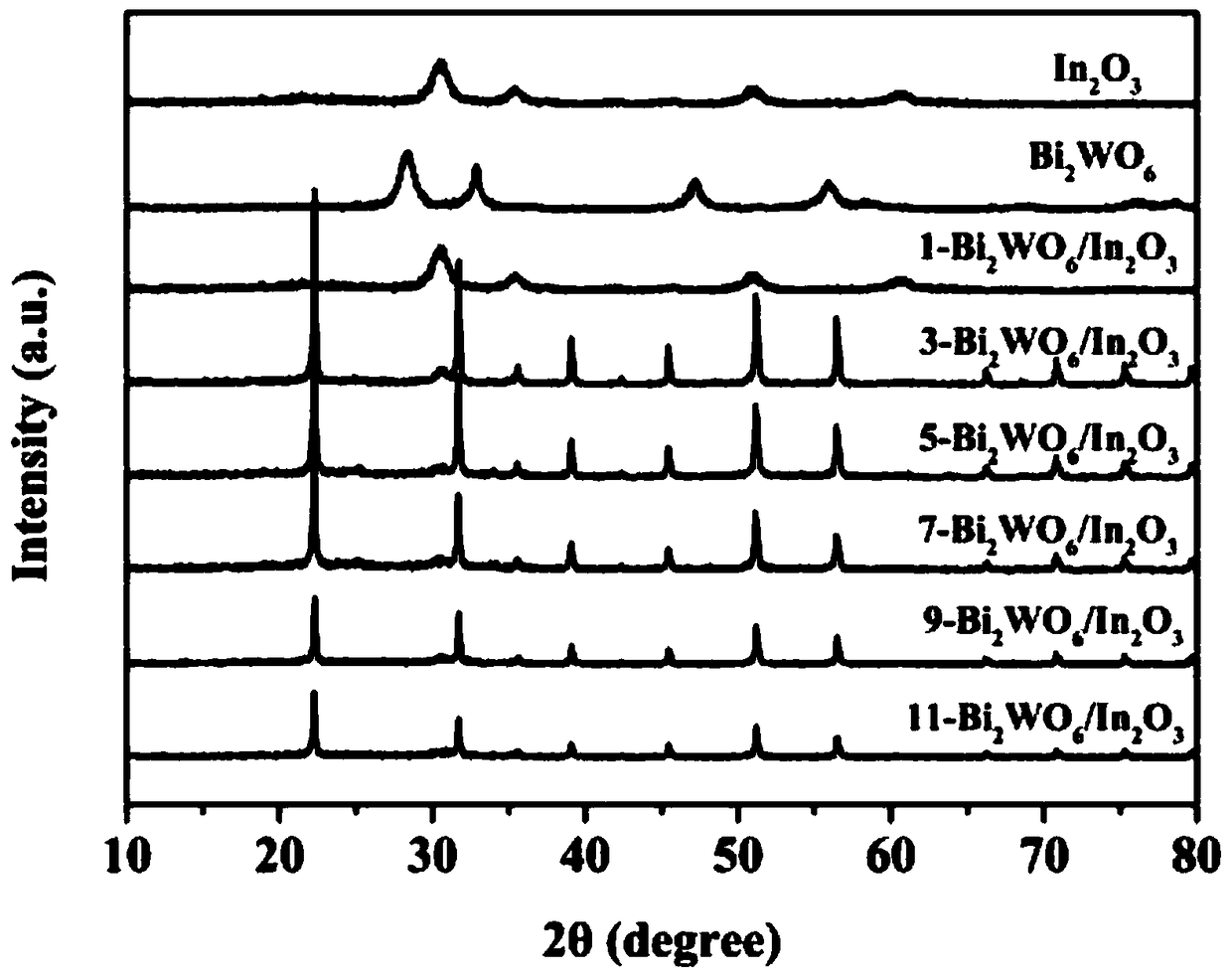

[0031] (2) Bi 2 WO 6 / In 2 o 3 Preparation of heterojunction composite photocatalyst:

[0032] Add 0.2g In 2 o 3 Add to a 50ml beaker containing 0.05g CTAB aqueous solution and stir for 30min; then slowly add 0.0028g Bi(NO 3 ) ...

Embodiment 2

[0035] (1)In 2 o 3 Preparation of micron flowers:

[0036] InCl 3 4H 2 O was added to a beaker containing 60ml deionized water and stirred for 30min; 1.2g sodium lauryl sulfate was added to the mixed solution and continued to stir for 30min; then 0.42g urea was added to the mixed solution and stirred for 1h; subsequently, the above mixed solution was transferred Carry out constant temperature thermal reaction in a 120° C. reaction kettle for 12 hours; after the reaction is completed, the temperature is lowered to room temperature, the solid product is washed with deionized water and ethanol, and dried to obtain InOOH. Calcinate InOOH at 500°C for 2h with a heating rate of 2°C / min to remove H 2 O gets pale yellow In 2 o 3 micron flower.

[0037] (2) Bi 2 WO 6 / In 2 o 3 Preparation of heterojunction composite photocatalyst:

[0038] Add 0.2g In 2 o 3 Add to a 50ml beaker containing 0.05g CTAB aqueous solution and stir for 30min; then slowly add 0.0083g Bi(NO 3 ) ...

Embodiment 3

[0041] (1)In 2 o 3 Preparation of micron flowers:

[0042] InCl 3 4H 2 O was added to a beaker containing 60ml deionized water and stirred for 30min; 1.2g sodium lauryl sulfate was added to the mixed solution and continued to stir for 30min; then 0.42g urea was added to the mixed solution and stirred for 1h; subsequently, the above mixed solution was transferred Carry out constant temperature thermal reaction in a 120° C. reaction kettle for 12 hours; after the reaction is completed, the temperature is lowered to room temperature, the solid product is washed with deionized water and ethanol, and dried to obtain InOOH. Calcinate InOOH at 500°C for 2h with a heating rate of 2°C / min to remove H 2 O gets pale yellow In 2 o 3 micron flower.

[0043] (2) Bi 2 WO 6 / In 2 o 3 Preparation of heterojunction composite photocatalyst:

[0044] Add 0.2g In 2 o 3 Add to a 50ml beaker containing 0.05g CTAB aqueous solution and stir for 30min; then slowly add 0.0139g Bi(NO 3 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com