Composite structure enhanced dual-material powder forging part and preparation method thereof

A technology of powder metallurgy and composite structure, applied in the field of powder metallurgy, can solve the problems of waste, low performance requirements of the core parts of parts, high cost, etc., and achieve the effects of reducing waste, avoiding insufficient diffusion, and enhancing bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

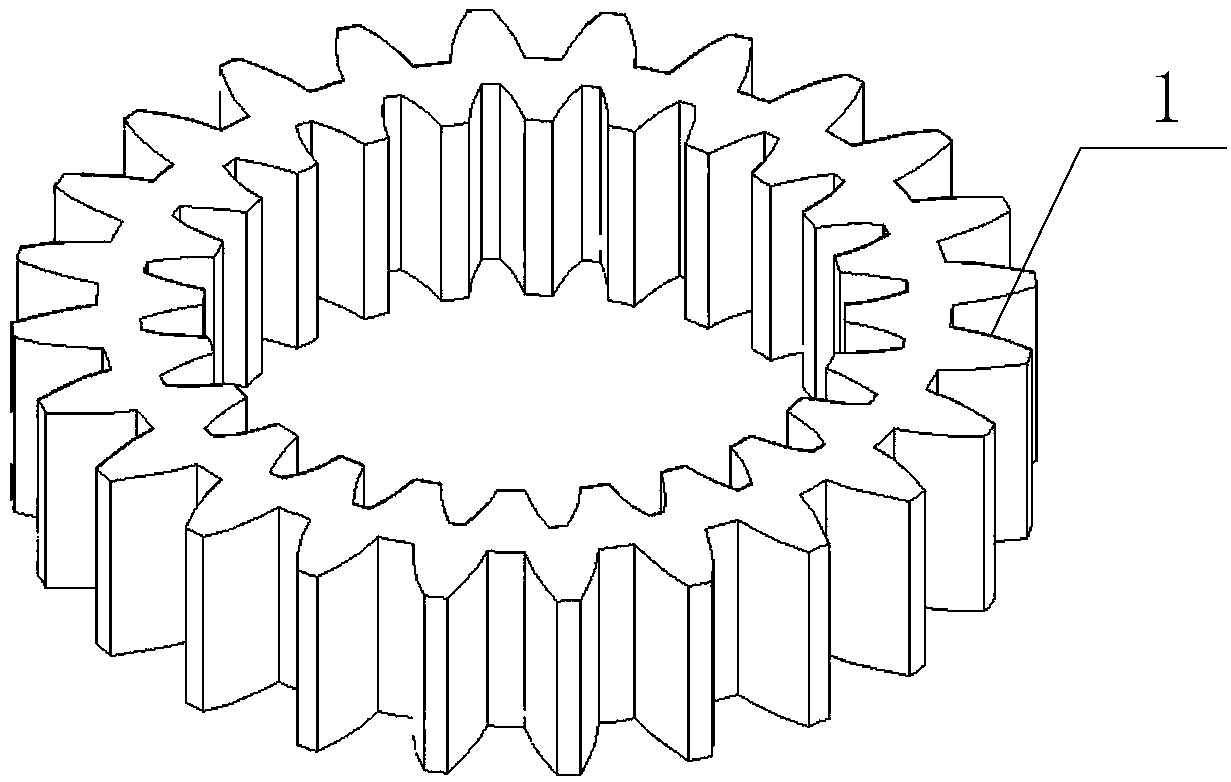

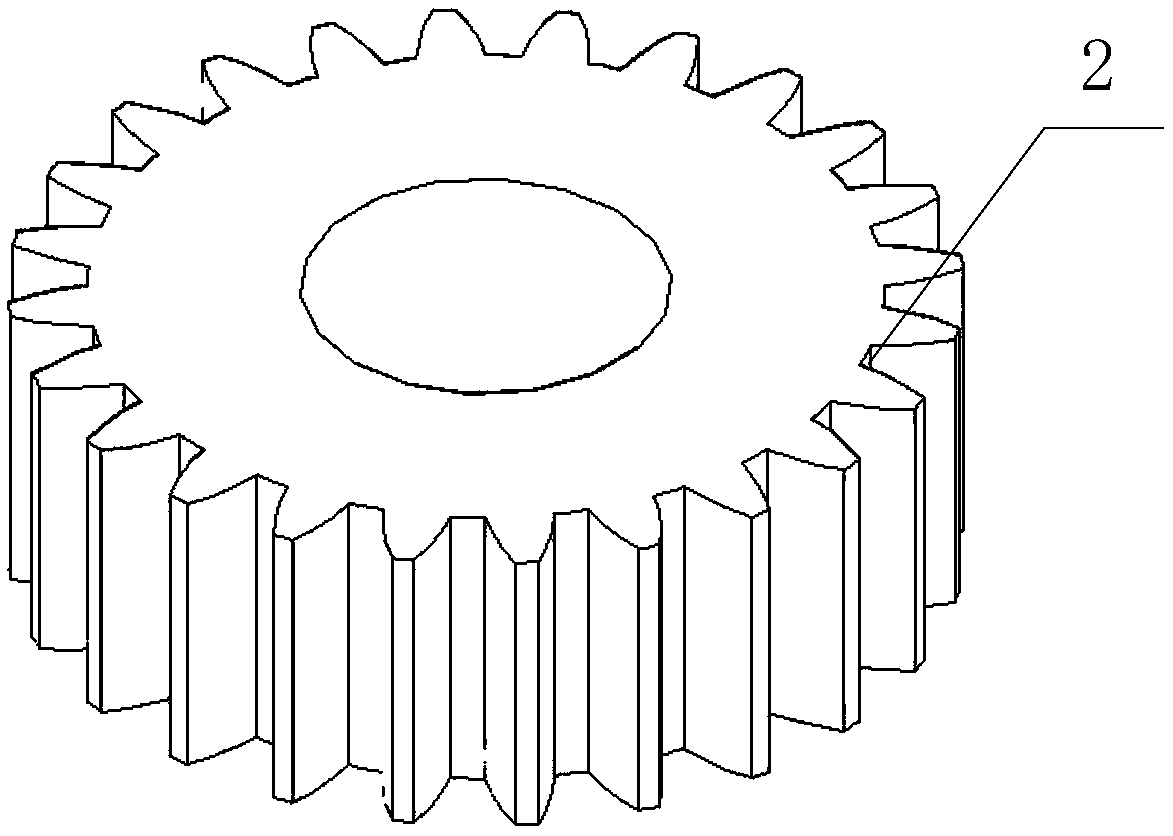

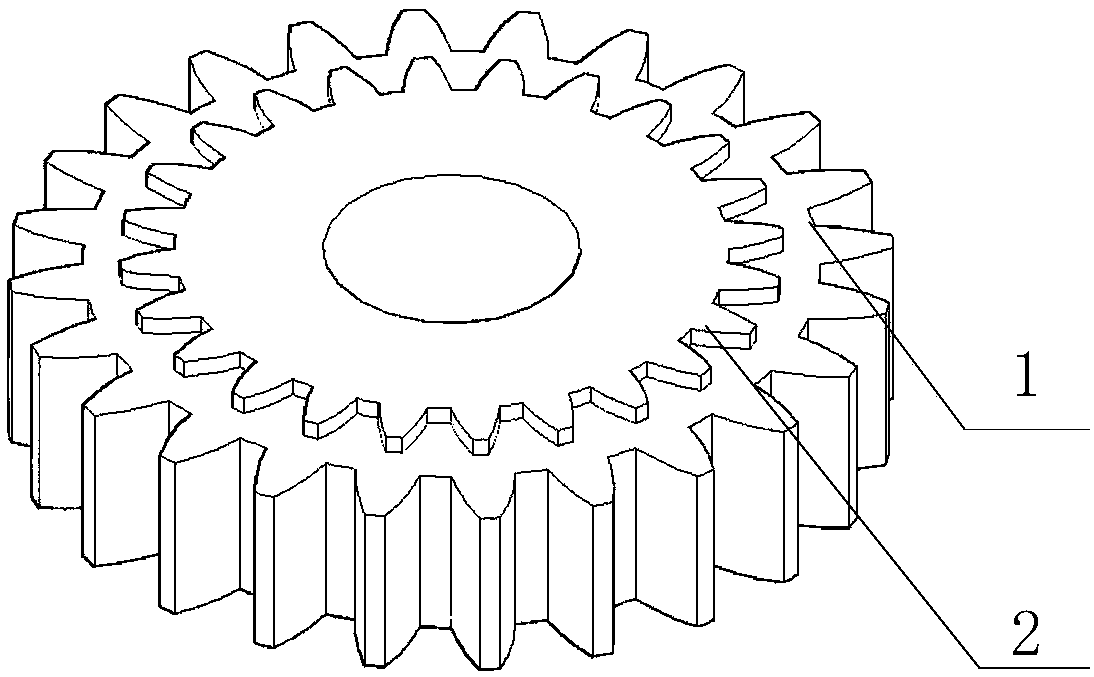

[0040] The invention relates to a dual-material powder metallurgy forging part with a composite reinforced structure and a preparation method thereof. Parts include at least a functional layer 1 and a supporting layer 2, and the supporting layer 2 is set in the functional layer 1; the functional layer 1 is an alloy with excellent comprehensive properties, which is selected according to the material performance requirements of the specific use environment, and the specific properties include strength / specific strength , hardness, wear resistance, corrosion resistance, electrical conductivity, thermal conductivity, etc. The support layer 2 is selected according to the requirements of the stable structure. The basic requirements only include strength indicators, and other additional requirements are determined according to the use environment and with reference to the functional layer 1.

[0041] The connection between the functional layer 1 and the support layer 2 realizes the n...

Embodiment 1

[0050] Embodiment 1 (Fe-Ni-Mo-Cu and Fe-C-Cu composite structure gear)

[0051] 1) Directly use a commercially available profile with the same composition as the functional layer, and process it into the required shape and internal structure according to the design drawings; Fe-Ni-Mo-Cu profile composition mass percentage: nickel 1-2%, molybdenum 0.4 -0.6%, copper 0.8-1%, graphite 0.5-0.64%, lubricant 0.45-0.6%, and the balance is iron; the obtained functional layer is as figure 1 shown;

[0052] 2) Fe-C-Cu composition mass percentage: copper 1-2%, graphite 0.5-0.64%, lubricant 0.45-0.6%, the balance is iron, weigh the raw material powder according to the above-mentioned composition respectively, fully in the powder mixer well mixed;

[0053] 3) Determine the size of the support layer and the amount of raw materials according to the Deform finite element simulation software. In the cavity of the cold press mold, the inner side of the functional layer processed in step 1) is ...

Embodiment 2

[0056] Embodiment 2 (Fe-Ni-Mo-Cu and Fe-C-Cu composite structure gear)

[0057] 1) Fe-Ni-Mo-Cu composition mass percentage: nickel 1-2%, molybdenum 0.4-0.6%, copper 0.8-1%, graphite 0.5-0.64%, lubricant 0.45-0.6%, the balance is iron; Fe -C-Cu component mass percentage: copper 1.00-2.00%, graphite 0.5-0.64%, lubricant 0.45-0.6%, and the balance is iron. Weigh the raw material powders according to the above ingredients, and mix them fully and evenly in the powder mixer;

[0058] 2) According to the size of the functional layer and the amount of raw materials determined by the Deform finite element simulation software, put the premixed Fe-Ni-Mo-Cu powder into the powder injection molding machine, the preheating temperature is 150°C, the injection temperature is 200°C, and Injection molding in the mold cavity to obtain the functional layer; the obtained functional layer is as follows figure 1 shown;

[0059] 3) According to the size of the support layer and the amount of raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com