Star-shaped polyester compound and preparation method thereof

A compound and polyester technology, applied in the field of polymer materials, can solve the problems of high bulk viscosity and high crystallinity, and achieve the effects of cheap and easy-to-obtain raw materials, convenient and practical operation, and good practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

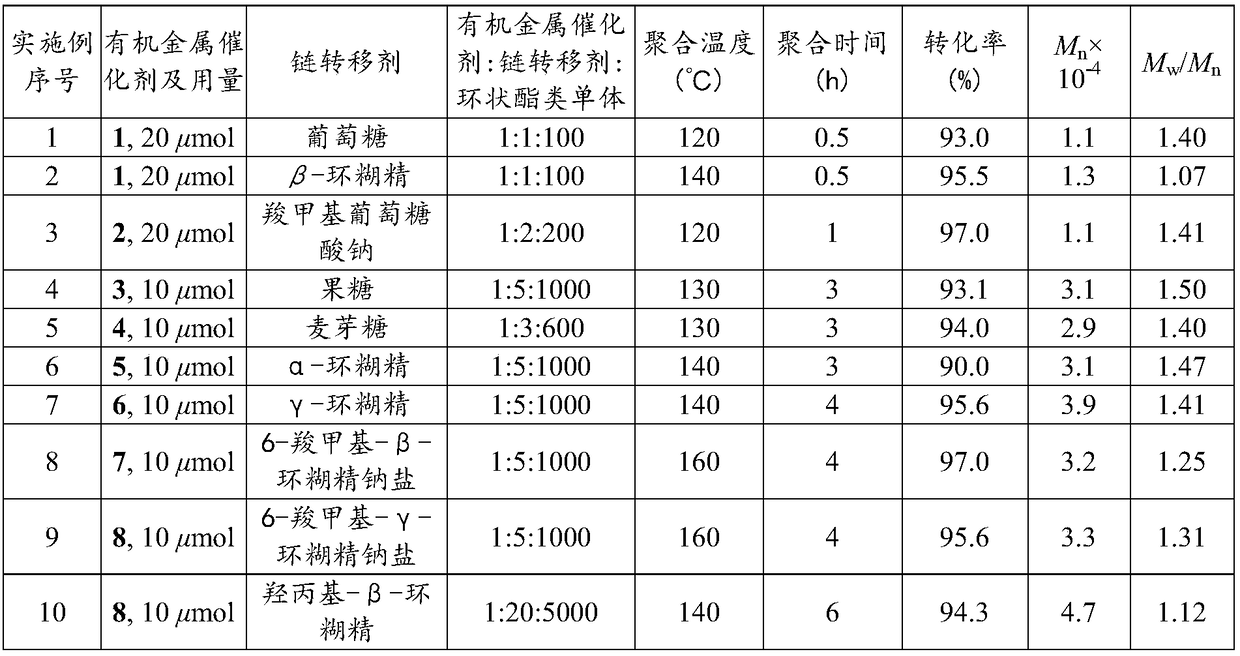

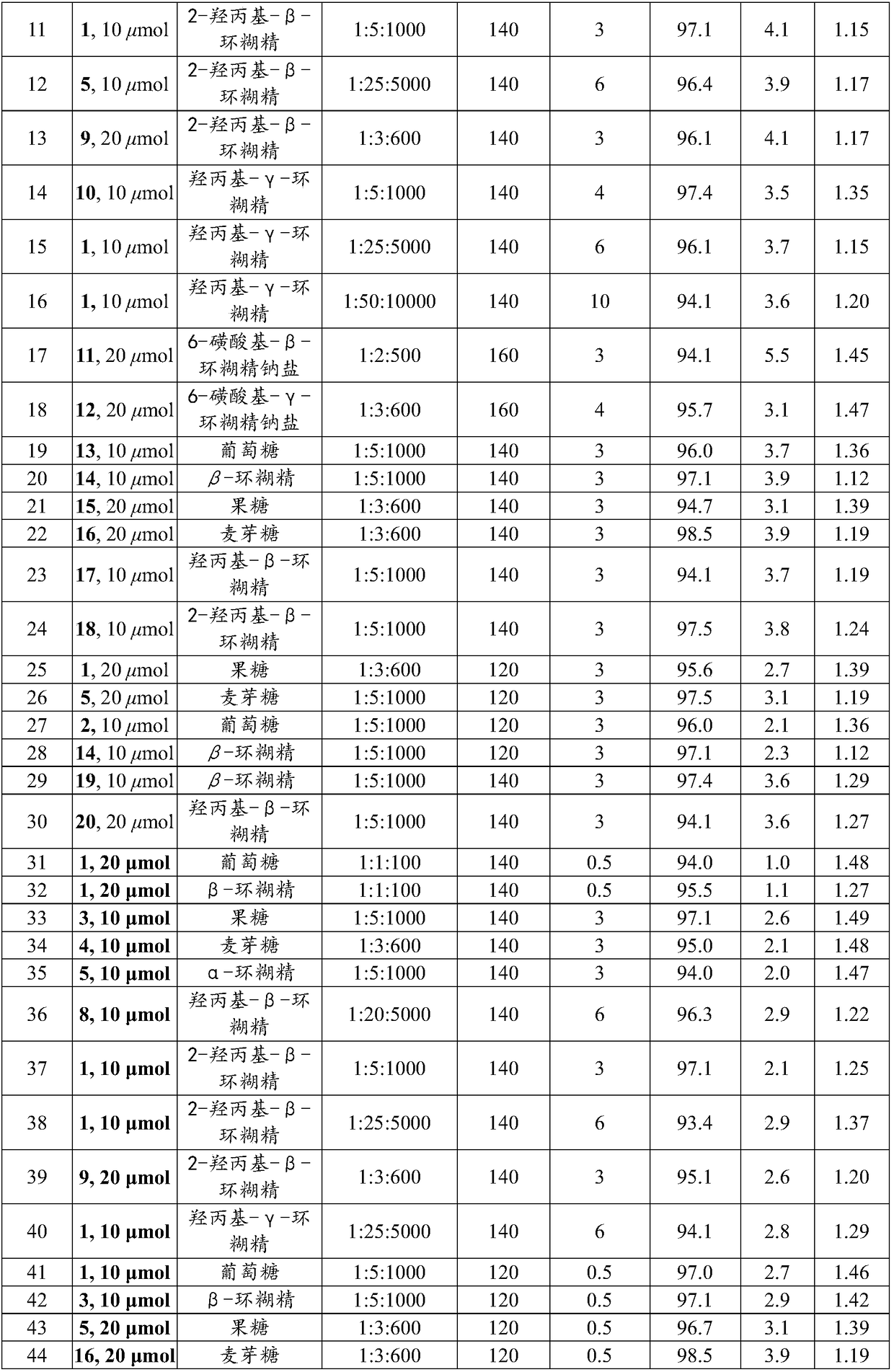

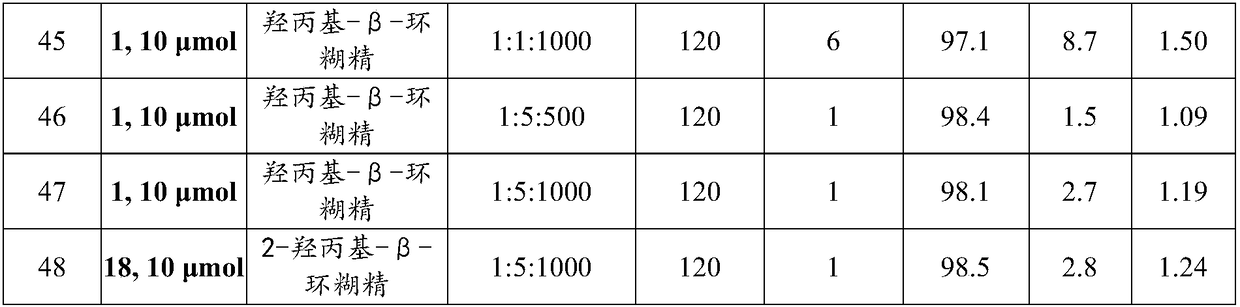

Examples

preparation example Construction

[0015] The embodiment of the present invention provides a kind of preparation method of star polyester compound, it comprises:

[0016] The sugar molecule is used as a chain transfer center, the sugar molecule is mixed with a cyclic ester monomer, and a ring-opening polymerization reaction occurs under the catalysis of an organic metal catalyst.

[0017] Macromolecules with topological structures such as dendritic, comb-shaped, hyperbranched, star-shaped, and H-shaped branched chain structures and ring-shaped topological polymers are of great significance in the fields of material modification, nanotechnology and biomedicine. New functional polymers with important application prospects have been paid more and more attention by people. However, due to the cumbersome preparation process of polymers with topological structures, its research progress is greatly limited. The preparation method provided by the embodiment of the present invention uses cheap and easy-to-obtain sugar ...

Embodiment 1

[0053] This embodiment provides a kind of star polyester compound, and its preparation method is as follows:

[0054] S1. At room temperature, add 20 μmol of metal catalyst 1 (stannous octanoate), 20 μmol of chain transfer agent (glucose), and 2000 μmol of cyclic ester monomer (L-propane) to 25 ml of anhydrous and anaerobic-treated polymerization bottle. lactide). At 120°C, the reaction was stirred for 30 minutes.

[0055] S2. After adding 0.5 vol% hydrochloric acid to acidify THF to dissolve, settle in industrial ethanol.

[0056] S3. The solid component obtained by settling is dried in a vacuum oven for 48h to obtain the required star-shaped polyester compound (2.68g, conversion rate 93.0%, M n = 11,000, M w / M n = 1.40).

Embodiment 2

[0058] This embodiment provides a kind of star polyester compound, and its preparation method is as follows:

[0059] S1. At room temperature, add 20 μmol metal catalyst 1 (stannous octanoate), 20 μmol chain transfer agent (β-cyclodextrin), and 2000 μmol cyclic ester monomer to a 25 ml anhydrous and anaerobic-treated polymerization bottle (L-lactide). At 140°C, the reaction was stirred for 30 minutes.

[0060] S2. After adding 0.5 vol% hydrochloric acid to acidify THF to dissolve, settle in industrial ethanol.

[0061] S3. The solid component obtained by settling is dried in a vacuum oven for 48h to obtain the required star-shaped polyester compound (2.75g, conversion rate 95.5%, M n = 13,000, M w / M n = 1.07).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com