Preparation method of In2O3 particles/In2O3 fiber composite material as well as obtained product

A fiber composite material, in2o3 technology, used in fiber processing, spinning solution preparation, textile and papermaking, etc., to achieve the effect of large output, single product composition and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1.1 Dissolve 0.2593 g of sucrose and 0.0819 g of p-phenylenediamine in 4 mL of DMF, then add 1 mL of ethanol, 0.5642 g of indium chloride (InCl 3 ), 0.8000 g of PVP to form a mixed solution, and stirred until transparent to obtain a precursor spinning solution.

[0029] 1.2 The precursor fiber was obtained by electrospinning the precursor spinning liquid. The spinning parameters were: positive voltage 18KV, negative voltage 0.5 KV, receiving distance 18 cm, and syringe advancing speed 0.001 mm / s.

[0030] 1.3 Place the precursor fiber in a muffle furnace, raise the temperature from room temperature to 600 °C at a rate of 1 °C / min in an air atmosphere, keep it for 2 h, and obtain the product after the sample is cooled with the furnace.

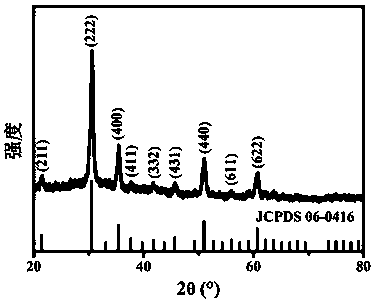

[0031] The XRD result of the product is as follows figure 1 As shown, it can be seen from the figure that all the diffraction peaks are consistent with the standard XRD card (06-0416), proving that the obtained product is cubic ferroma...

Embodiment 2

[0033] 2.1 Dissolve 0.1217 g of sucrose and 0.0664 g of p-phenylenediamine in 4 mL of DMF, then add 1 mL of ethanol, 0.3611 g of InCl 3 , 0.6749 g of PVP to form a mixed solution, stirred until transparent to obtain a precursor spinning solution.

[0034] 2.2 The precursor fiber was obtained by electrospinning the precursor spinning solution. The spinning parameters were: positive voltage 16KV, negative voltage 0.5 KV, receiving distance 20 cm, and syringe advancing speed 0.002 mm / s.

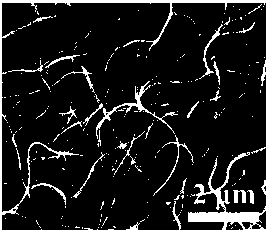

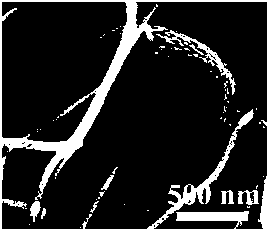

[0035] 2.3 Place the precursor fiber in a muffle furnace, and raise the temperature from room temperature to 650 °C at a rate of 2 °C / min in an air atmosphere, and keep it warm for 9 h. After the sample is cooled with the furnace, In 2 o 3 Particles / In 2 o 3 fiber composites. The composite material has good dispersion and no agglomeration phenomenon. It is composed of In 2 o 3 Spherical particles and In 2 o 3 Fiber composite, in which the surface of the spherical particles are long with ...

Embodiment 3

[0037] 3.1 Dissolve 0.3810 g of sucrose and 0.0697 g of p-phenylenediamine in 4 mL of DMF, then add 1 mL of ethanol, 0.6545 g of InCl 3 , 0.7404 g of PVP to form a mixed solution, stirred until transparent to obtain a precursor spinning solution.

[0038] 3.2 The precursor fiber was obtained by electrospinning the precursor spinning solution. The spinning parameters were: positive voltage 20KV, negative voltage 0.5 KV, receiving distance 16 cm, and syringe advancing speed 0.001 mm / s.

[0039] 3.3 Place the precursor fiber in a muffle furnace, raise the temperature from room temperature to 550 °C at a rate of 1 °C / min in an air atmosphere, and keep it warm for 3 h. After the sample is cooled with the furnace, In 2 o 3 Particles / In 2 o 3 fiber composites. The composite material has good dispersion and no agglomeration phenomenon. It is composed of In 2 o 3 Spherical particles and In 2 o 3 Fiber composite, in which the surface of the spherical particles are long with In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com