Lithium battery electrolyte and preparation method thereof

An electrolyte and lithium battery technology, applied in the field of lithium battery electrolyte and its preparation, can solve the problems of increased aging of lithium batteries, degradation of lithium battery performance, easy combustion or explosion, etc., and achieves excellent safety performance and high-temperature cycle performance. The effect of gas production and repairing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

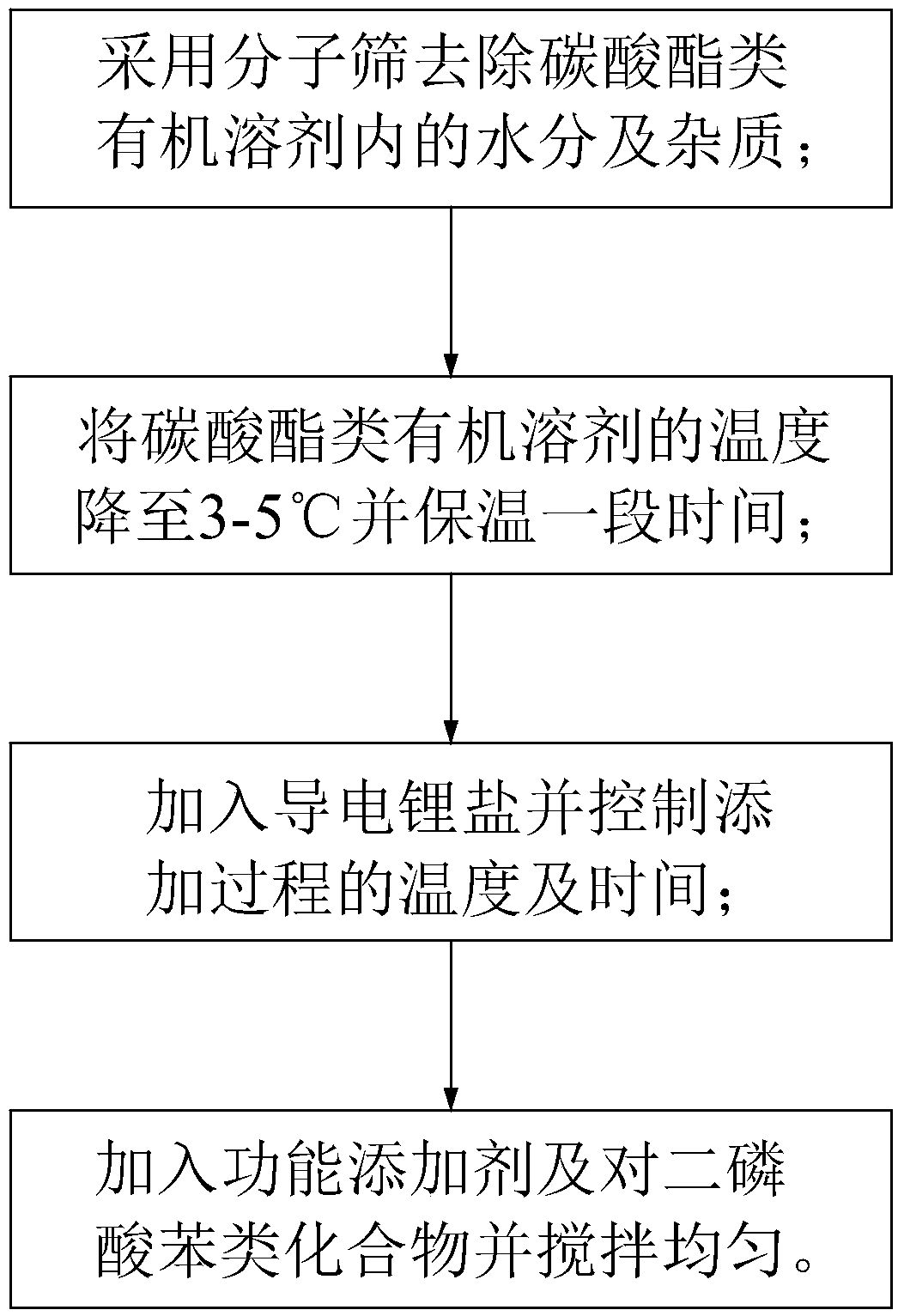

[0032] see figure 1 , the present invention also provides a kind of preparation method of lithium battery electrolyte, comprises the following steps:

[0033]1) Molecular sieves are used to remove moisture and impurities in the carbonate organic solvent, so that the water content of the carbonate organic solvent is ≤5ppm and the purity is ≥99.995%;

[0034] 2) Use a refrigeration device to lower the carbonate organic solvent from room temperature to 3-5°C and control the time required for cooling to 15-25min, and then keep it warm at 3-5°C for 10-20min;

[0035] 3) Slowly add the conductive lithium salt to the carbonate organic solvent and ensure that the temperature during the addition process is lower than 10°C, and the adding time of the conductive lithium salt is controlled at 60-90min;

[0036] 4) Add functional additives and benzene p-diphosphate compounds as high-temperature stabilizers and mix and stir for 20-30 minutes, and make the conductive lithium salt, the funct...

Embodiment 1

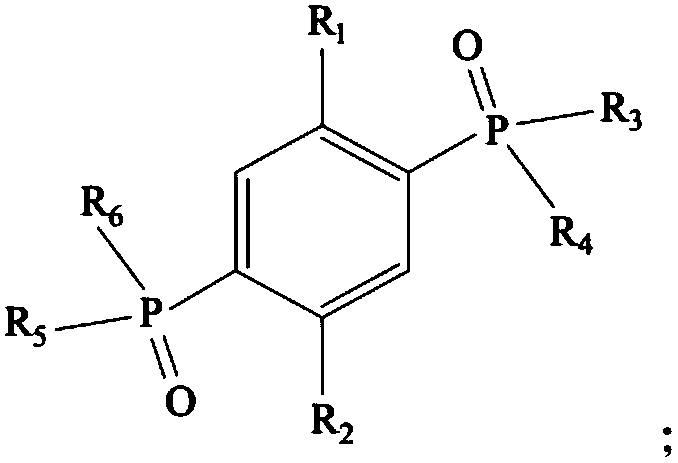

[0042] In this embodiment, the organic solvent is a carbonate-based organic solvent mixed with various carbonates. Specifically, the carbonate-based organic solvent contains carbonic acid with a mass fraction of 25%, 45%, 20% and 10% respectively. Ethyl methyl ester, dimethyl carbonate, ethylene carbonate and propylene carbonate; LiPF is used for conductive lithium salt 6 with LiBF 4 The functional additive selects vinylene carbonate and biphenyl for use; the p-diphosphate benzene compound selects p-diphosphate methyl benzene as the high-temperature stabilizer, and its structural formula is as follows:

[0043]

[0044] LiPF 6 、LiBF 4 The mass fractions of , vinylene carbonate, biphenyl and methyl p-diphosphate relative to the total mass of the electrolyte are 12%, 2%, 5%, 0.8% and 1.5%, respectively.

[0045] In the preparation process, first, ethyl methyl carbonate, dimethyl carbonate, ethylene carbonate and propylene carbonate are respectively removed from moisture an...

Embodiment 2

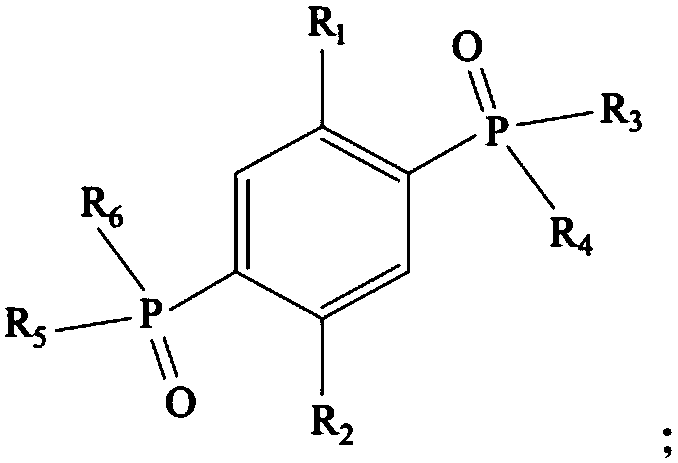

[0047] The preparation method is basically the same as in Example 1, except that the p-diphosphate benzene compounds used as the high-temperature stabilizer are selected from p-diphosphate ethyl benzobenzene, and its structural formula is as follows:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com