Parallel-arranged SiO2 nanowire and preparation method thereof

A parallel-arranged, nanowire technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve the problems of unproven performance and application, uncontrollable size, and uneven morphology and other problems, to achieve the effect of low deposition substrate, low cost and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one, a preparation of parallel arrangement of SiO 2 The nanowire method is realized by the following steps.

[0021] Step 1: Pre-treat the base Si wafer, sonicate it with acetone, and clean it with plasma water. Clean the quartz boat with alcohol.

[0022] Step 2. Use SiO nanopowder as the reaction source into one end of the quartz boat, and then place the processed substrate Si wafer in the quartz boat to ensure that it is above the reaction source and does not contact the reaction source. The quartz boat of the source is put into a high-temperature tube furnace filled with Ar protective gas.

[0023] Step 3: Raise the temperature in the furnace to a suitable temperature for the reaction source to react, and keep it for 2 hrs. After the reaction, the temperature in the furnace was lowered to a low temperature. After taking it out, it was found that white flocs had grown on the substrate, which was the parallel arrangement of SiO as described in 1. 2 Nano...

Embodiment 1

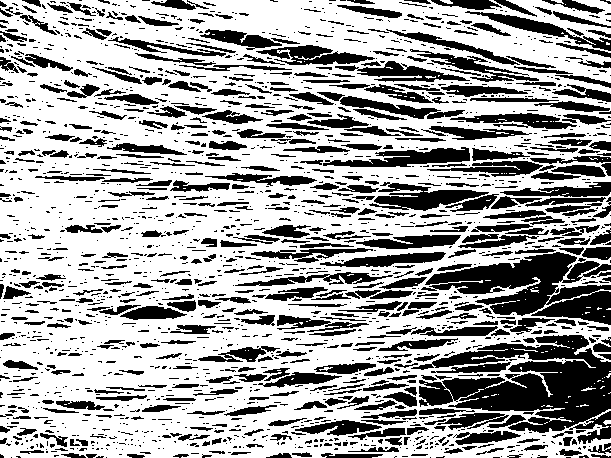

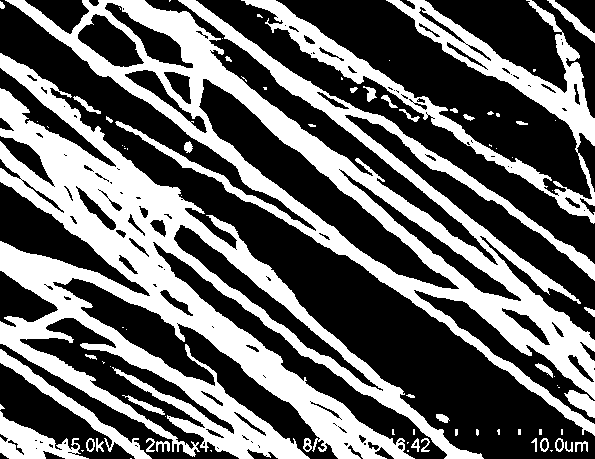

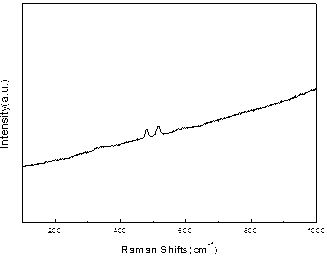

[0033] Use 0.5 g SiO nanopowder as the reaction source and put it into the bottom of the quartz boat, use the n-type (111) Si wafer as the substrate and place it in the quartz boat, then place the quartz boat in the quartz chamber of the horizontal tube furnace, adjust the reaction source and The position of the substrate is such that the reaction source is in the high temperature area of the tube furnace and the substrate is in the relatively low temperature area. Before heating, flow 90 ml / min of argon gas into the system to remove air impurities in the reaction system, and then heat the tube furnace to 1150 ºC and keep it for 2 hrs, and wait until the system is in an argon environment. After cooling to room temperature, white flocs were found as nanowires growing on the Si substrate in the area of 1130-1140 ºC, see figure 1 with figure 2 , The diameter of the nanowire is 0.3-0.5 microns, and the length is greater than 100 microns. image 3 SiO arranged in parallel 2 EDX ...

Embodiment 2

[0035] Use 0.7g SiO nanopowder as the reaction source and put it into the bottom of a quartz boat, use n-type (111) Si wafer as the substrate and place it in the quartz boat together, then place the quartz boat in the quartz chamber of the horizontal tube furnace to adjust the reaction The positions of the source and the substrate make the reaction source position in the high temperature area of the tube furnace and the substrate in the relatively low temperature area. Before heating, flow 80 ml / min of argon gas into the system to remove air impurities in the reaction system, and then heat the tube furnace to 1140ºC and keep it for 2 hrs, and wait for the system to cool down in an argon environment After reaching room temperature, white flocs were found to grow on the Si substrate at 1120-1130 ºC, and parallel nanowires with a diameter of 0.3-0.5 microns were observed to grow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com