Method for treating high-concentration alkaline resin desorption liquid by catalytic ozonation technique

A basic resin, ozone oxidation technology, applied in the oxidation water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of difficult biochemical treatment, strong alkalinity, etc., to improve the reaction speed and utilization rate. Improve and enhance the effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

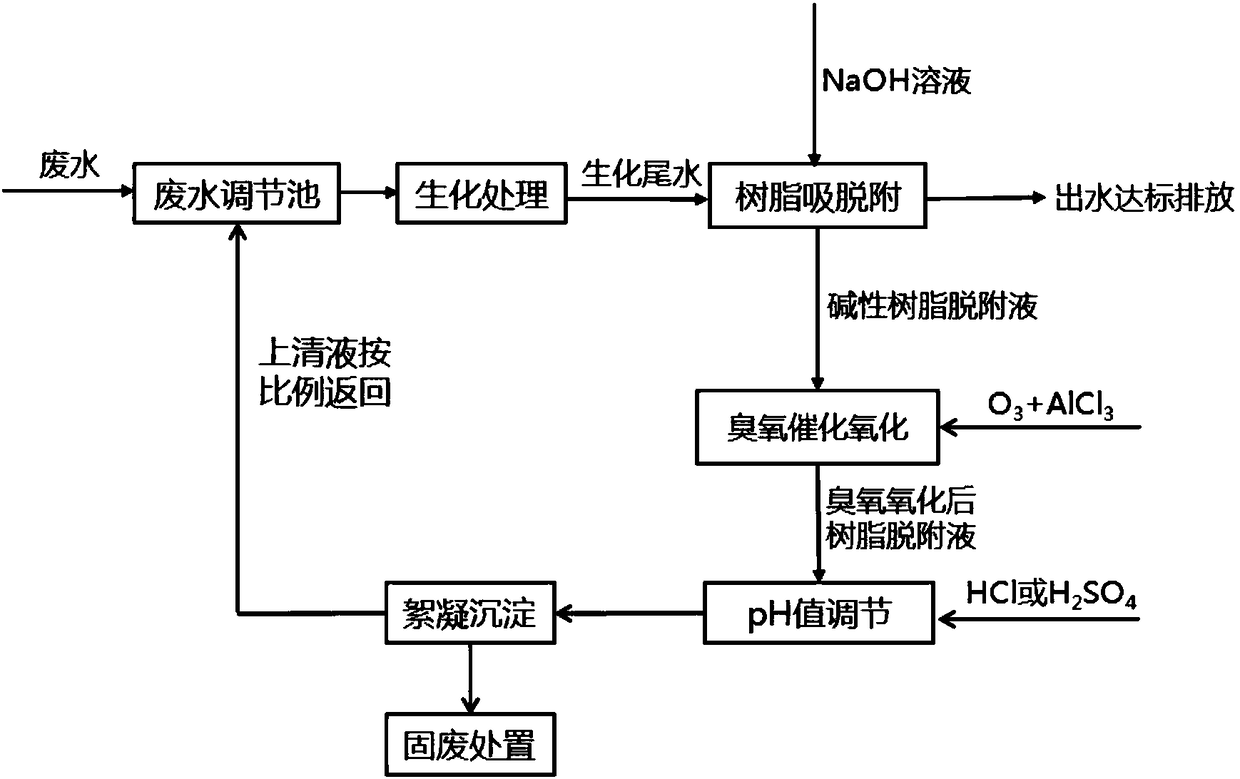

[0045] Such as figure 1 As shown, a certain industrial wastewater enters the wastewater regulating tank and discharges biochemical tail water (B / C value is 0.01) after biochemical treatment. ) carry out the elution of ion-exchange resin and reclaim basic resin desorption liquid as alkali eluent, described basic resin desorption liquid comprises sodium hydroxide, inorganic ion and organic matter, and described sodium hydroxide mass concentration is 8 %, the total concentration of the inorganic ions is less than 200mg / L, wherein the inorganic ions include Na + 、K + , Mg 2+ , Ca 2+ , Cl - 、PO 3 3- , SO 4 2- , the content of the organic matter is 10000mg / L, wherein the organic matter includes humic acid, fulvic acid, aromatic compound, and microbial metabolites; then successively add aluminum chloride and ozone to the recovered alkaline resin desorption liquid, wherein the chlorine The input amount of aluminum is to drop into 5g aluminum chloride in the alkaline resin des...

Embodiment 2

[0047] Such as figure 1 As shown, a certain industrial wastewater enters the wastewater regulating tank and discharges biochemical tail water (B / C value is 0.02) after biochemical treatment. After adsorption and saturation of ion exchange resin, sodium hydroxide solution (the mass concentration of sodium hydroxide solution is 4% ) carry out the elution of ion-exchange resin as alkali eluent and reclaim basic resin desorption liquid, described basic resin desorption liquid comprises sodium hydroxide, inorganic ion and organic matter, and described sodium hydroxide mass concentration is 4 %, the total concentration of the inorganic ions is less than 200mg / L, wherein the inorganic ions include Na + 、K + , Mg 2+ , Ca 2+ , Cl - 、PO 3 3- , SO 4 2- , the content of the organic matter is 5000mg / L, wherein the organic matter includes humic acid, fulvic acid, aromatic compound, and microbial metabolites; then successively add aluminum chloride and ozone to the recovered alkaline...

Embodiment 3

[0049] Such as figure 1 As shown, a certain industrial wastewater enters the wastewater regulating tank and discharges biochemical tail water (B / C value is 0.05) after biochemical treatment. After adsorption and saturation of ion exchange resin, sodium hydroxide solution (the mass concentration of sodium hydroxide solution is 2% ) carry out the elution of ion-exchange resin and reclaim basic resin desorption liquid as alkaline eluent, described basic resin desorption liquid comprises sodium hydroxide, inorganic ion and organic matter, and described sodium hydroxide mass concentration is 2 %, the total concentration of the inorganic ions is less than 200mg / L, wherein the inorganic ions include Na + 、K + , Mg 2+ , Ca 2+ , Cl - 、PO 3 3- , SO 4 2- , the content of the organic matter is 2000mg / L, wherein the organic matter includes humic acid, fulvic acid, aromatic compound, microbial metabolites; then successively add aluminum chloride and ozone to the recovered alkaline r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com