Device for culturing microalga processing biogas slurry to couple with anaerobic fermentation and operation method thereof

An anaerobic fermentation and operation method technology, applied in enzymology/microbiology devices, methods of supporting/immobilizing microorganisms, biomass post-treatment, etc., can solve the problems of long time, low efficiency of biogas slurry treatment, and non-recyclable water resources and other problems to achieve the effect of saving water resources and improving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

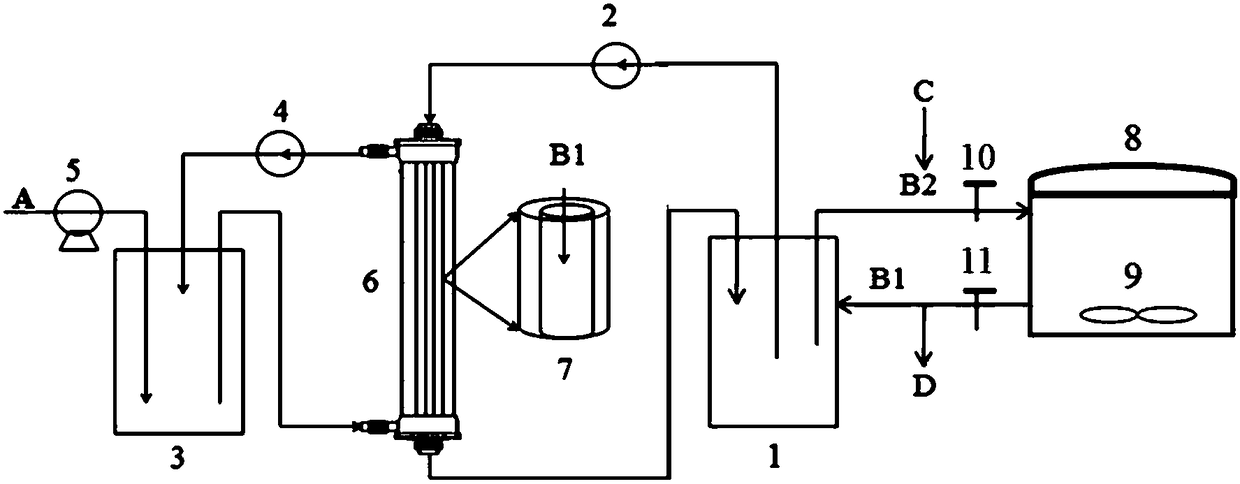

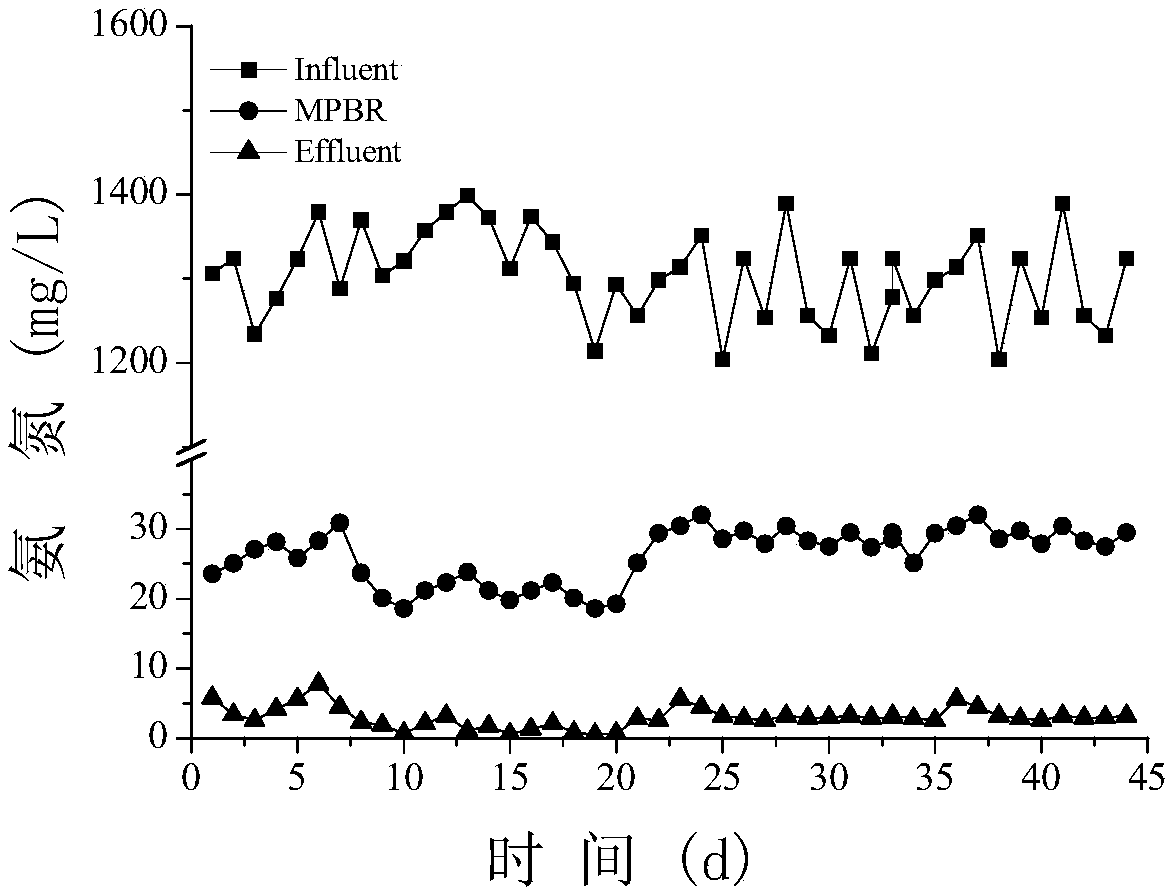

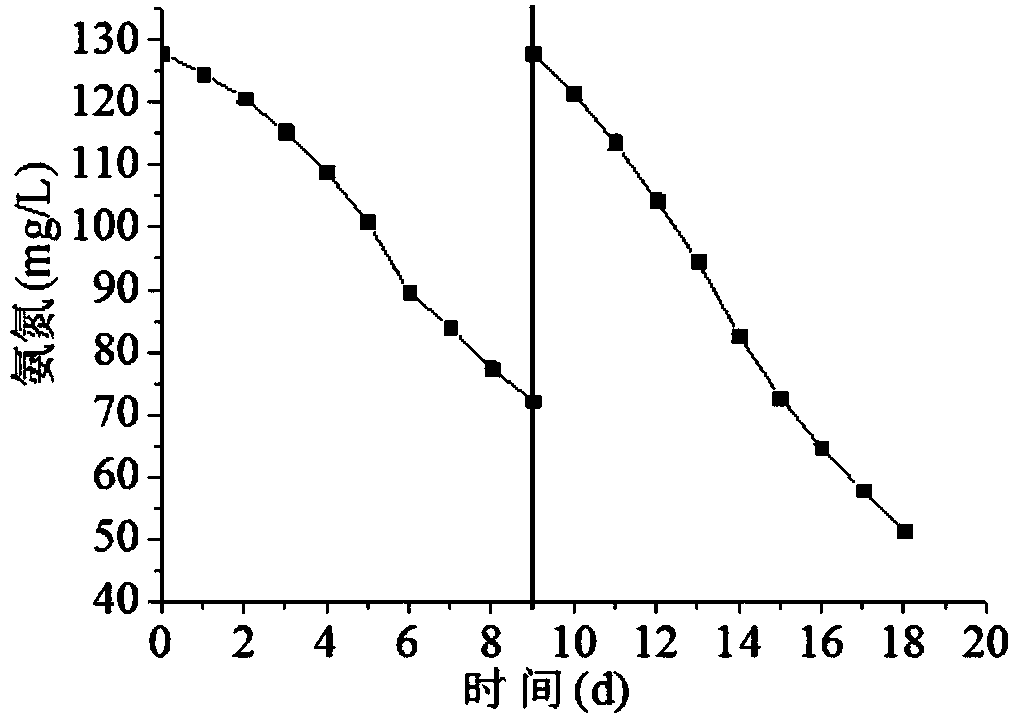

[0042]In the membrane photobioreactor coupled with semi-continuous anaerobic fermentation, firstly, the daily waste slag discharged from the semi-continuous anaerobic fermentation tank is separated, and the separated biogas slurry is added to the biogas slurry storage tank. Add 1000 mL of microalgae liquid containing 0.1 g / L of C.sorokiniana in the microalgae cultivation tank. The membrane photobioreactor is placed in a light incubator, the temperature in the incubator is set at 25°C, and the light intensity is 7200Lux. The air of 1L / L min was introduced into the microalgae culture tank through the air pump. The peristaltic pump drives the microalgae to circulate outside the membrane at a circulation flow rate of 150-160mL / min, so that the biogas slurry can maintain a circulation flow at a flow rate of 50-60mL / min in the hollow fiber membrane. After 1 day of cultivation, the ammonia nitrogen of the biogas slurry dropped from about 1300mg / L to about 3mg / L.

[0043] Under the ...

Embodiment 2

[0045] In the semi-continuous anaerobic fermentation of the coupling device, firstly, 40-60mL of treated biogas slurry discharged from the membrane photobioreactor per day is mixed with 40-60g of pig manure and then added to the biogas slurry storage tank. The semi-continuous anaerobic fermentation tank is placed in a biochemical incubator, the rotating speed of the mixing agitator at the bottom of the tank is set at 100-200 r / min, and the temperature in the biochemical incubator is 37°C. The biogas output of the semi-continuous anaerobic fermentation tank is about 800mL / d.

[0046] Divide water to replace the treated biogas slurry, keep the same parameters as the previous batch of fermentation raw materials, temperature, stirring rate, etc., the biogas output of the semi-continuous anaerobic fermentation tank in the control group is about 800mL / d, which is the same as that using the treated biogas slurry as raw material There was no significant difference in the gas productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com