Preparation method and product of hydrogel plaster for cold compress

The technology of hydrogel sticker and cold compress is applied in the field of preparation of cold compress hydrogel sticker, which can solve the problems of difficult coating and sizing process of hydrogel sticker, difficult control of cross-linking reaction speed, difficult dispersion of functional additives and the like. The gel forming process is controllable, the cross-linking curing speed is guaranteed, and the coating operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

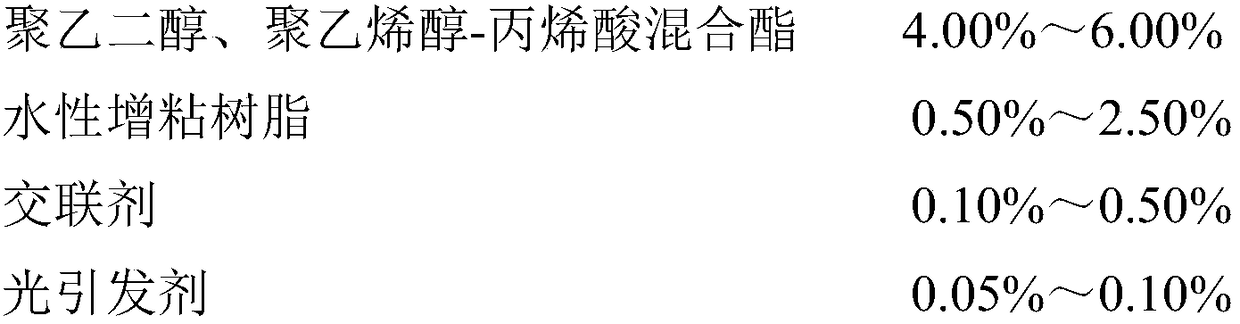

Method used

Image

Examples

Embodiment 1

[0045] First, add 300.00kg of polyethylene glycol 600 and 200.00kg of polyethylene glycol 400 to the reaction kettle with condenser and water separator, start the agitator, then add 25.00kg of polyvinyl alcohol, heat to 95°C, keep warm Stir until the polyvinyl alcohol is completely dissolved; then cool down to 60°C, add 80.10kg acrylic acid, 259.00g hydroquinone, 260.00kg xylene, 0.87kg solid acid catalyst (purchased from Jiangyin Nanda Synthetic Chemical Co., Ltd. HND-31 solid superacid catalyst), heated to the reaction system reflux phenomenon, and maintained at this temperature for the reaction; when most of the theoretical water yield was evaporated (the steamed water was more than 90% of the theoretical moisture), stop heating , to end the reaction, lower the temperature to 40.0°C, filter out the material to recover the solid acid catalyst, then send it to a closed stirred tank for vacuum extraction and recover the solvent xylene, and get polyethylene glycol and polyvinyl ...

Embodiment 2

[0051] First, add 300.00kg of polyethylene glycol 600 and 200.00kg of polyethylene glycol 400 into the reaction kettle with condenser and water separator, start the agitator, then add 15.00kg of polyvinyl alcohol, heat to 90°C, keep warm Stir until the polyvinyl alcohol is completely dissolved; then cool down to 50°C, add 82.00kg acrylic acid, 80.00g tert-butylcatechol, 200.00kg benzene, 2.40kg solid acid catalyst (purchased from Jiangyin Nanda Synthetic Chemical Co., Ltd. HND-33 solid super acid catalyst), heat until the reaction system appears reflux phenomenon, and maintain the reaction at this temperature; when the reaction reaches the point where most of the theoretical water output is evaporated, stop heating, end the reaction, cool down to 40.0°C, and filter out the material The solid acid catalyst is recovered, and then sent to a closed stirred tank for vacuum extraction and the solvent benzene is recovered, and polyethylene glycol and polyvinyl alcohol-acrylic acid mix...

Embodiment 3

[0057] First, add 300.00kg of polyethylene glycol 600 and 200.00kg of polyethylene glycol 400 to the reaction kettle with condenser and water separator, start the agitator, then add 20.00kg of polyvinyl alcohol, heat to 93°C, keep warm Stir until the polyvinyl alcohol is completely dissolved; then cool down to 55°C, add 81.30kg acrylic acid, 167.00g p-hydroxyanisole, 233.00kg toluene, 1.25kg solid acid catalyst (purchased from Jiangyin Nanda Synthetic Chemical Co., Ltd. HND-34 solid super acid catalyst), heat until the reaction system appears reflux phenomenon, and maintain the reaction at this temperature; when the reaction reaches the point where most of the theoretical water output is evaporated, stop heating, end the reaction, cool down to 40.0°C, and filter out the material The solid acid catalyst is recovered, and then sent to a closed stirred tank for vacuum extraction and the solvent toluene is recovered, and polyethylene glycol and polyvinyl alcohol-acrylic acid mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com