Preparation method of novel multilayer brazing super-hard abrasive tool

A superhard abrasive and brazing solder technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the structural design optimization of multi-layer brazing abrasives, the grinding effect is not obvious, and the multi-layer grinding Difficulty in chipping and other problems, to achieve the effect of ensuring continuous working ability, small artificial influence factors, and controllable chip removal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

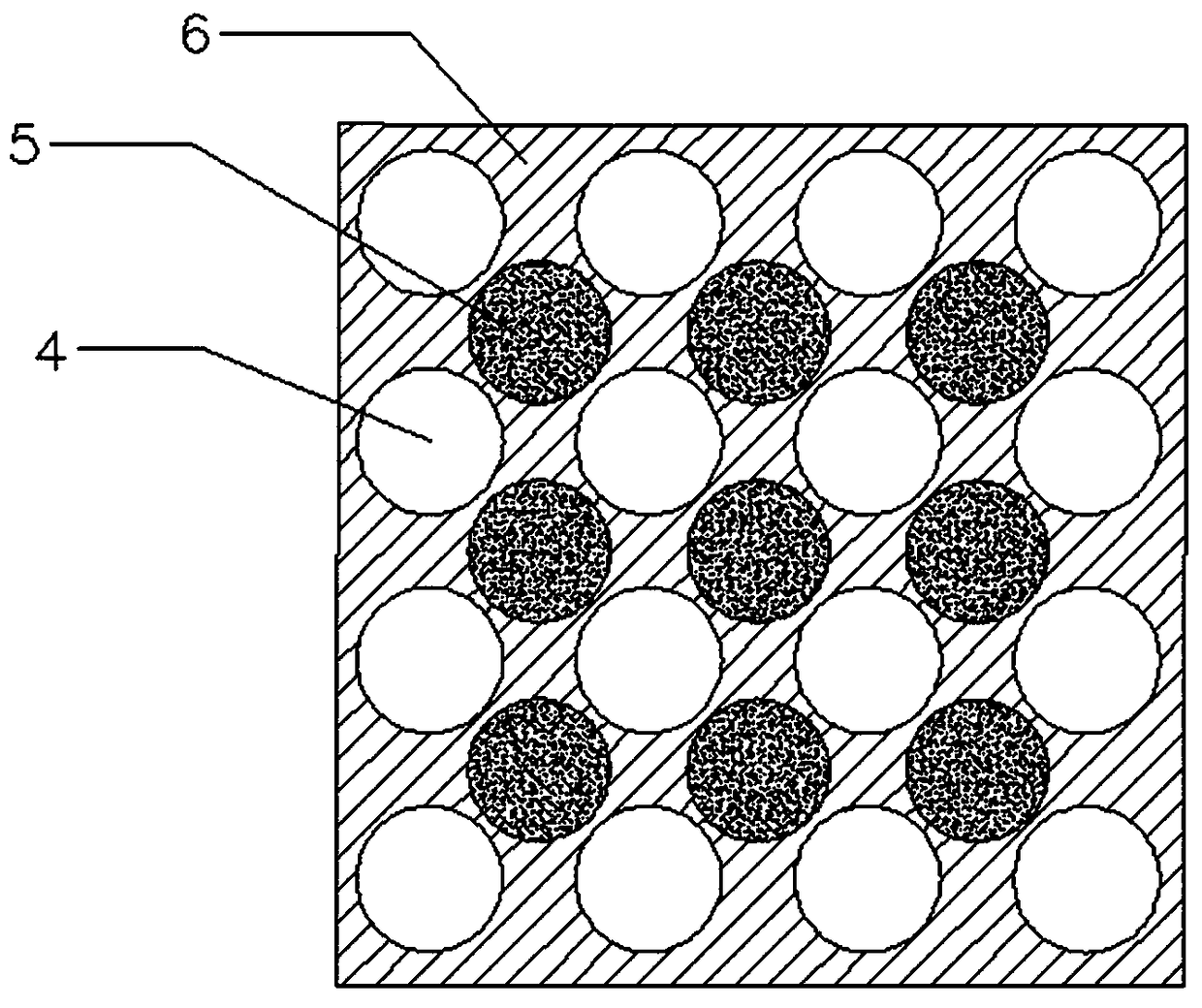

[0045] Now a multi-layer brazing grinding disc is needed to grind the surface of metal materials. The size of the grinding disc is 125mm, and it is formed by preparing 10 multi-layer brazing blanks with length×width×height=40mm×10mm×4mm and then brazing through a vacuum brazing furnace. Preparation steps:

[0046] The first step is to determine that the dilution material is SiO 2 Particles, the particle size is 120 mesh, the brazing solder is copper-based solder, its composition is copper-tin-titanium, the content percentage is: copper 60%-65%, tin 20%-27%, titanium 16%-26%. The particle size is 120 mesh. The super-hard abrasive is artificial diamond, the grade is high-grade wear-resistant type, and the particle size is 40 / 50 mesh. The diluted material and brazing solder are compounded into a composite material at a volume ratio of 1:2.

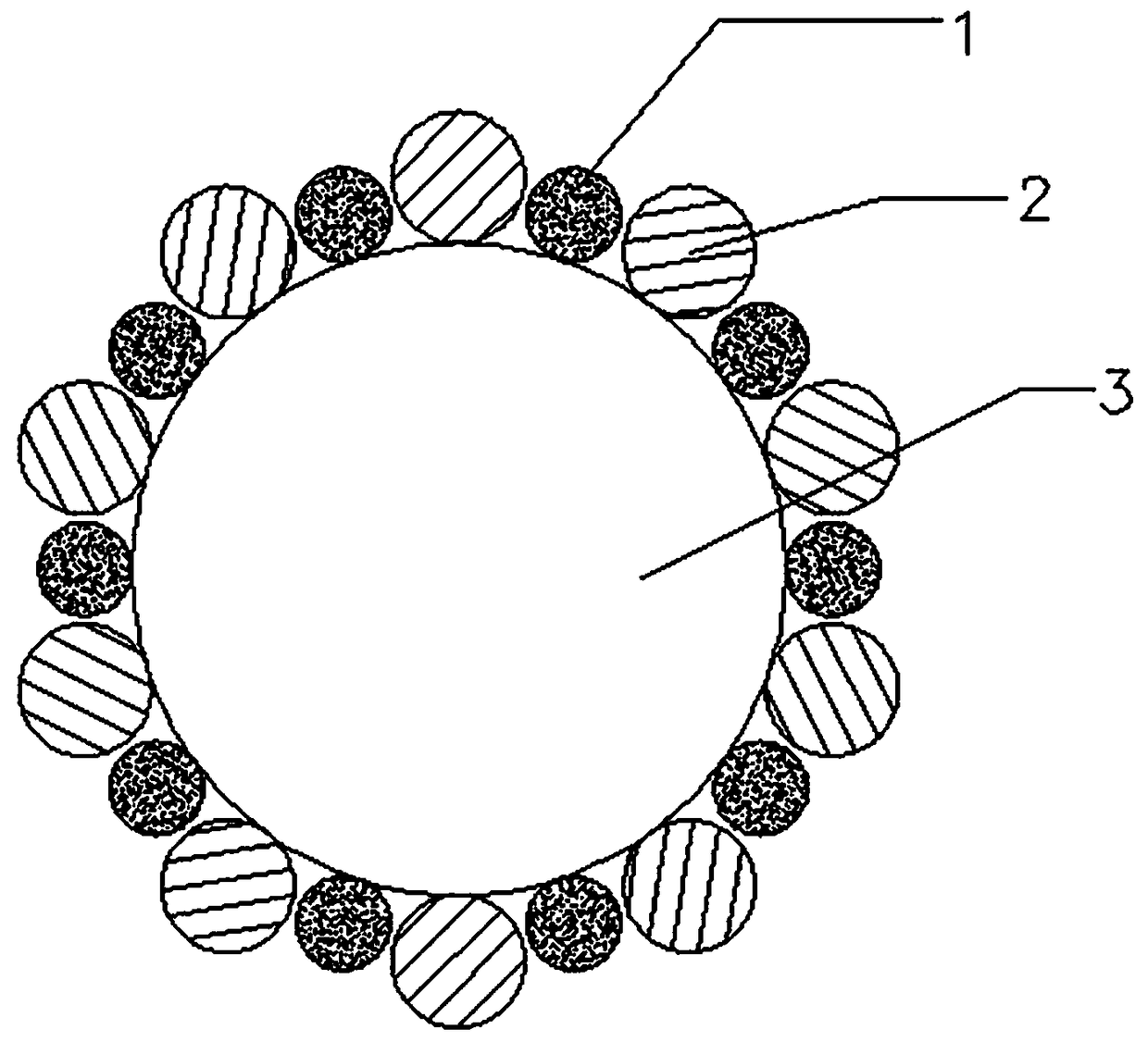

[0047] The second step is to granulate and wrap the superhard abrasive grains. The composition of the wrapping is the composite material...

Embodiment 2

[0052] Now a multi-layer brazing grinding disc is needed to grind the surface of metal materials. The size of the grinding disc is 125mm, and it is formed by preparing 10 multi-layer brazing blanks with length×width×height=40mm×10mm×4mm and then brazing through a vacuum brazing furnace. Preparation steps:

[0053] The first step is to determine that the dilution material is SiO 2 Particles, the particle size is 120 mesh, the brazing solder is copper-based solder, its composition is copper-tin-titanium, the content percentage is: copper 60%-65%, tin 20%-27%, titanium 16%-26%. The particle size is 120 mesh. Silicon carbide is selected as the superabrasive, and the diluted material and brazing solder are mixed at a volume ratio of 2:1 to form a composite material.

[0054] The second step is to granulate and wrap the superhard abrasive grains. The composition of the wrapping is the composite material prepared in step 1. The abrasive wrapping is bonded and fixed with a water-so...

Embodiment 3

[0059] Now a multi-layer brazing grinding disc is needed to grind the surface of metal materials. The size of the grinding disc is 125mm, and it is formed by preparing 10 multi-layer brazing blanks with length×width×height=40mm×10mm×4mm and then brazing through a vacuum brazing furnace. Preparation steps:

[0060] The first step is to determine that the dilution material is SiO 2 Particles, the particle size is 120 mesh, the brazing solder is copper-based solder, its composition is copper-tin-titanium, the content percentage is: copper 60%-65%, tin 20%-27%, titanium 16%-26%. The particle size is 120 mesh. Artificial diamond and polycrystalline diamond are selected as superabrasives, and the diluted material and brazing solder are mixed at a volume ratio of 1:5 to form a composite material.

[0061] The second step is to granulate and wrap the superhard abrasive grains. The composition of the wrapping is the composite material prepared in step 1. The abrasive wrapping is bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com