High-content 2-methyl allyl chloride preparation method

A methallyl chloride, high-content technology, applied in separation methods, halogenated hydrocarbon preparation, chemical instruments and methods, etc., can solve the problems of high energy consumption, large investment, complex separation process, etc., to simplify the separation process , reducing energy consumption and equipment investment, the effect of reducing the number of theoretical boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

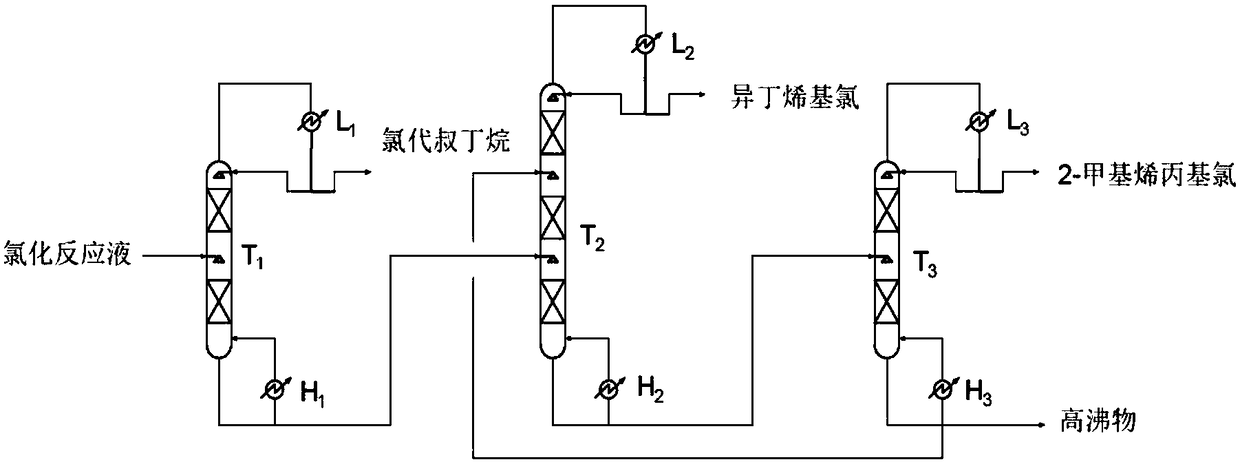

[0025] in such as figure 1 The middle part of the first rectification tower (theoretical plate total number is 20) of the shown three-tower continuous rectification device continuously adds chlorination reaction liquid (mass content is: 2-methallyl chloride is 89.6%, chlorine 2.3% tert-butane, 1.3% isobutenyl chloride, 5.6% 1,2-dichloro-tert-butane, 1.2% 3,3'-dichloroisobutene), adjust the reflux ratio to 50, and use the total feed from the top of the tower The ratio of amount 2.3% obtains the chloro-tert-butane that content is more than 99%; A mixture of 1,2-dichloro-tert-butane and 3,3'-dichloroisobutene (82:18 in mass ratio), 1,2-dichloro-tert-butane and 3,3'-dichloroisobutene is added to the middle and upper part The mixture and the mass ratio of the feed are controlled at 2:1, and the reflux ratio at the top of the tower is controlled at 230, and the content is obtained from the top of the tower with the ratio of 1.3% of the first tower feed amount and is the isobutenyl ...

Embodiment 2

[0027] in such as figure 1 The middle part of the first rectifying tower (theoretical plate total number is 20) of the shown three-tower continuous rectifying device continuously adds the chlorination reaction solution (mass content is: 2-methallyl chloride is 88.7%, chlorine 2.1% tert-butane, 1.5% isobutenyl chloride, 6.0% 1,2-dichloro-tert-butane, 1.5% 3,3'-dichloroisobutene), adjust the reflux ratio to 56, and use the total feed from the top of the tower The ratio of amount 2.1% obtains the tert-butyl chloride that content is more than 99%; A mixture of 1,2-dichloro-tert-butane and 3,3'-dichloroisobutene (80:20 in mass ratio), 1,2-dichloro-tert-butane and 3,3'-dichloroisobutene is added to the middle and upper part The mixture and the mass ratio of feed are controlled at 3:1, and the reflux ratio at the top of the tower is controlled at 180, and the content is obtained from the top of the tower with the ratio of 1.5% of the first tower feed amount and is the isobutenyl chl...

Embodiment 3

[0029] in such as figure 1The middle part of the first rectification tower (theoretical plate total number is 20) of the shown three-tower continuous rectification device continuously adds chlorination reaction liquid (mass content is: 2-methallyl chloride is 85.2%, chlorine isobutane 3.2%, isobutenyl chloride 3.6%, 1,2-dichloro-tert-butane 6.1%, 3,3'-dichloroisobutene 1.9%), adjust the reflux ratio to 37, and use the total feed from the top of the tower The ratio of amount 3.2% obtains the tert-butyl chloride that content is more than 99%; A mixture of 1,2-dichloro-tert-butane and 3,3'-dichloroisobutene (80:20 in mass ratio), 1,2-dichloro-tert-butane and 3,3'-dichloroisobutene is added to the middle and upper part The mixture and the mass ratio of feed are controlled at 1:1, and the reflux ratio at the top of the tower is controlled at 110, and the content is obtained from the top of the tower with the ratio of 3.6% of the first tower feed amount as isobutenyl chloride that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com