An anti-dripping integrated intumescent type halogen-free flame retardant and a preparing method thereof

An intumescent, anti-dripping technology, applied in the anti-dripping integrated intumescent halogen-free flame retardant and its preparation field, can solve problems such as troublesome handling, coarse anti-dripping agent particles, and increased water solubility, and achieve Effects of reducing water solubility, uniform and stable flame retardancy, improving processing resistance and precipitation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

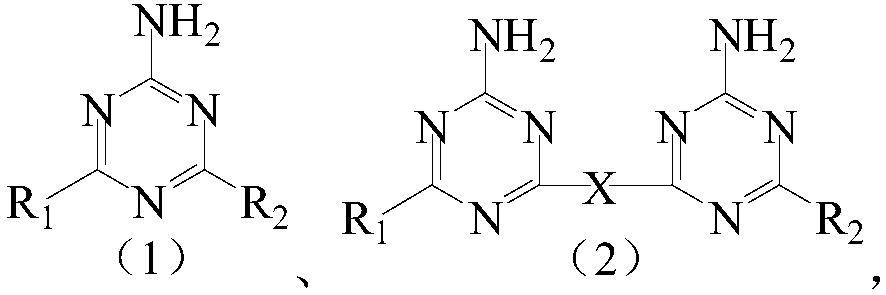

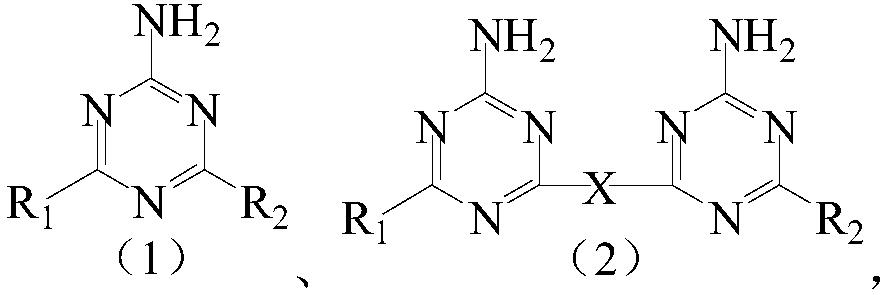

[0031] A preparation method of an anti-dripping integral expansion type halogen-free flame retardant, comprising the following steps:

[0032] 1) Add the triazine compound, dispersant and water into the reaction kettle, then add the formaldehyde solution, react at 60-100°C for 2-8 hours, and obtain the triazine compound prepolymer solution;

[0033] 2) Add phosphorus pentoxide and diammonium hydrogen phosphate into the kneader, preheat to 180-350°C, feed ammonia gas for reaction, and stop the ammonia gas flow after the reaction;

[0034] 3) Spray the polytetrafluoroethylene emulsion on the surface of the powder in the kneader by spraying equipment, heat, and feed ammonia gas for sintering;

[0035] 4) stop feeding ammonia and heating, nitrogen, obtain ammonium polyphosphate with polytetrafluoroethylene;

[0036] 5) Control the temperature in the kneader at 80-150°C, add the triazine compound prepolymer solution in step 1), react for 2-8 hours, then add curing agent, react for...

Embodiment 1

[0058] A preparation method of an anti-dripping integral expansion type halogen-free flame retardant, comprising the following steps:

[0059] 1) Add 32.2kg of triazine compound, 5kg of methanol and 25kg of water into the reactor, then add 24.35kg of formaldehyde solution with a mass fraction of 37%, and react at 80°C for 2 hours to obtain a triazine compound prepolymer solution;

[0060] 2) Add 81.44kg of phosphorus pentoxide and 79.56kg of diammonium hydrogen phosphate into the kneader, preheat to 330°C, and 3 The flow rate of / h is fed into the ammonia gas for 2 hours, and the ammonia gas is stopped after the reaction;

[0061] 3) 1.9kg polytetrafluoroethylene emulsion (DISP40, DuPont, mass fraction 60%) is evenly sprayed on the powder surface in the kneader by the spray equipment on the kneader, heated, and 3 The flow rate of / h is passed into ammonia gas for 2h, and sintering is carried out at 330°C;

[0062] 4) stop feeding ammonia gas and heating, with 3.5m 3 The flo...

Embodiment 2

[0066] A preparation method of an anti-dripping integral expansion type halogen-free flame retardant, comprising the following steps:

[0067] 1) Add 18kg of triazine compound, 2kg of ethanol and 20kg of water into the reactor, then add 32.46kg of formaldehyde solution with a mass fraction of 37%, and react at 90°C for 4 hours to obtain a triazine compound prepolymer solution;

[0068] 2) Add 74.60kg of phosphorus pentoxide and 69.40kg of diammonium hydrogen phosphate into the kneader, preheat to 280°C, and 3 The flow rate of / h is fed into the ammonia gas for 3 hours, and the ammonia gas is stopped after the reaction;

[0069] 3) Spray 1.6kg polytetrafluoroethylene emulsion (D3211, Solvay, mass fraction 60%) evenly on the powder surface in the kneader through the spray equipment on the kneader, heat, and 3 The flow rate of / h is passed into ammonia gas for 3h, and sintering is carried out at 280°C;

[0070] 4) Stop feeding ammonia gas and heating, with 2m 3 The flow rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com