MCA flame retardant nylon 66 composite material and preparation method thereof

A technology of composite materials and flame-retardant nylon, which is applied in the field of polyhexamethylene adipamide modification and terminal blocks, which can solve the problems of large fluctuations, failure to reach the V0 flame-retardant level, and high MCA addition, so as to reduce negative effect, the preparation method is simple and feasible, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

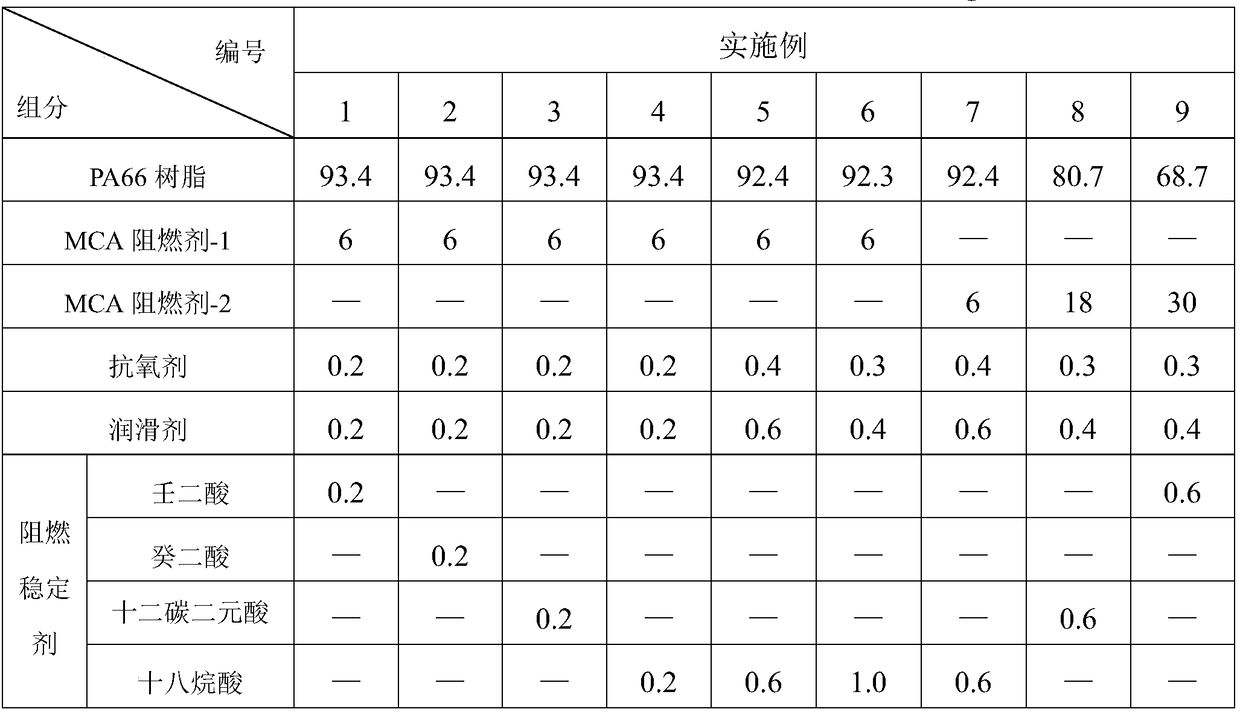

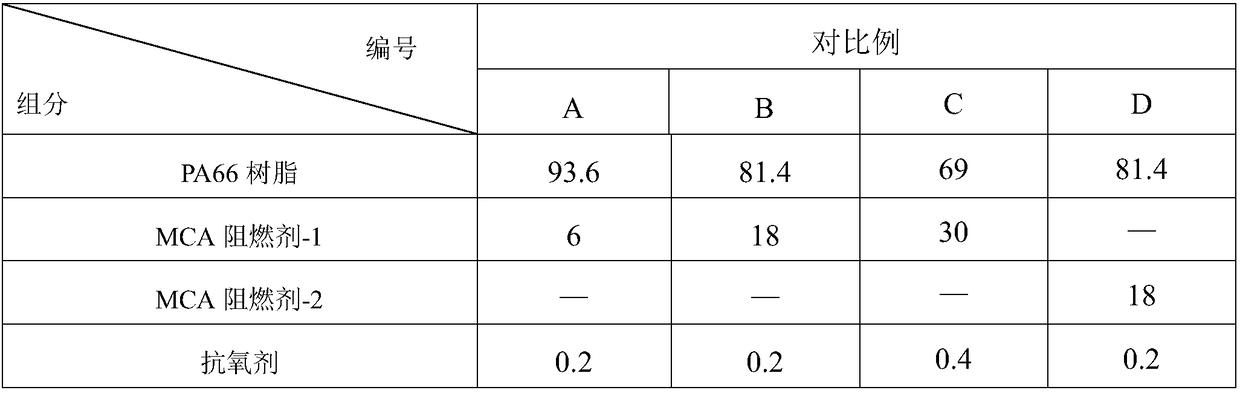

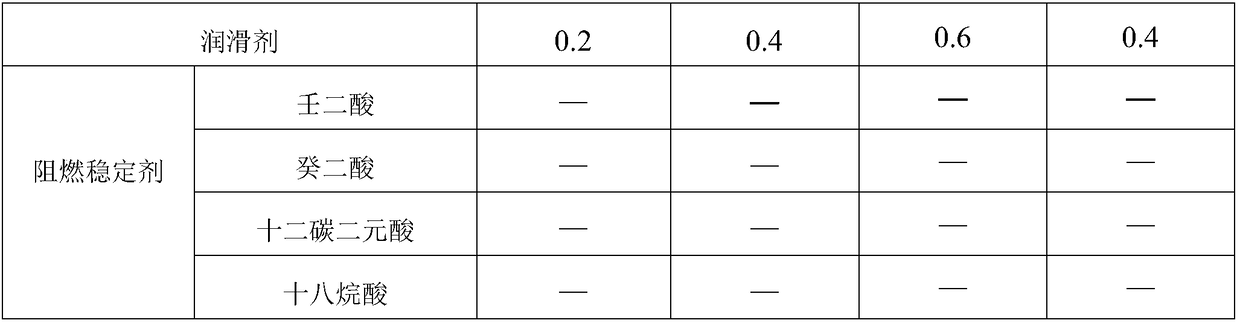

[0016] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific embodiments of the present invention will be further described in detail below in conjunction with specific examples and comparative examples. The following examples are used to illustrate the present invention. But it is not used to limit the scope of the present invention, especially not limited to the model of each component raw material used in the following specific examples.

[0017] The raw materials of each component used are as follows:

[0018] PA66 resin: PA66EP-158, Zhejiang Huafeng Group;

[0019] MCA flame retardant: MCA flame retardant-1, Shouguang Weidong Chemical Co., Ltd.;

[0020] MCA Flame Retardant-2, Sichuan Fine Chemicals;

[0021] Antioxidant: N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine (IRGANOX1098), BASF;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com