Nanometer foam acid, and preparation method and application method thereof

A technology of nano-foam and nano-silica, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced effective action distance of acid liquid, inability to realize deep penetration acid fracturing, acid liquid leakage, etc. , to achieve the effect of increasing the acidification penetration distance, good retarding effect, and uniform acid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

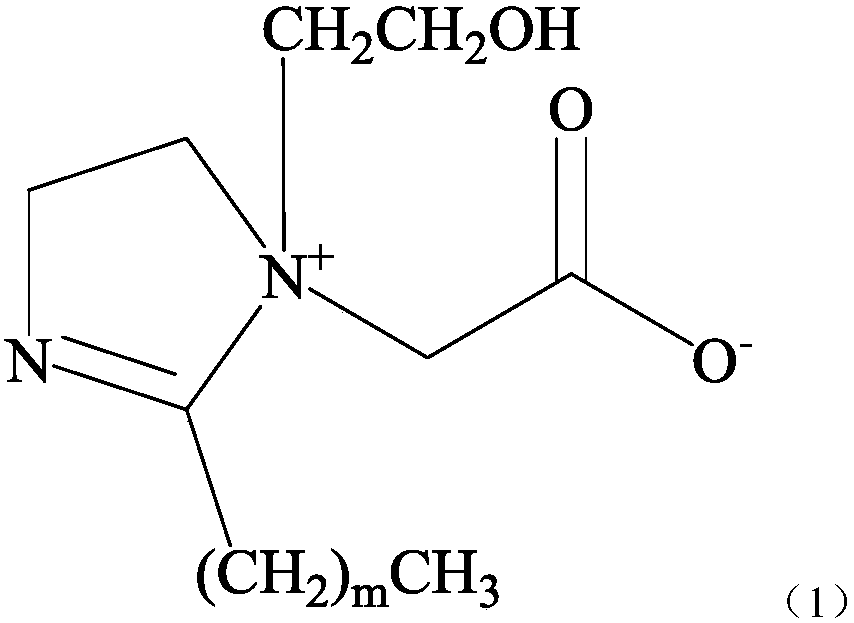

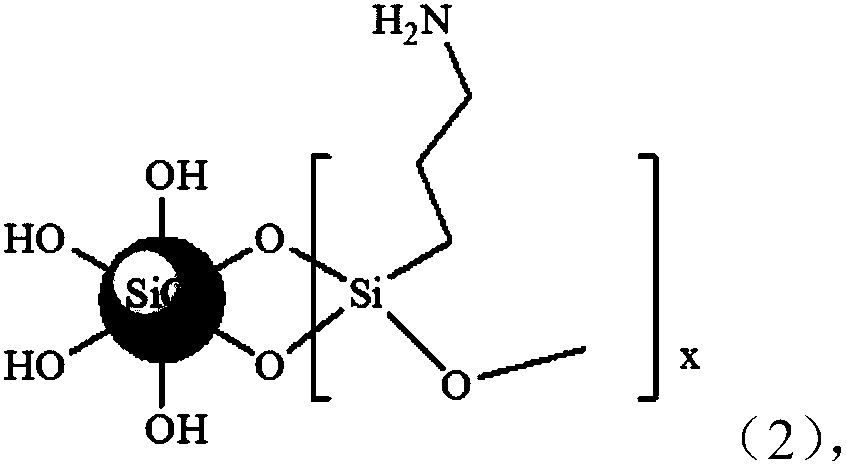

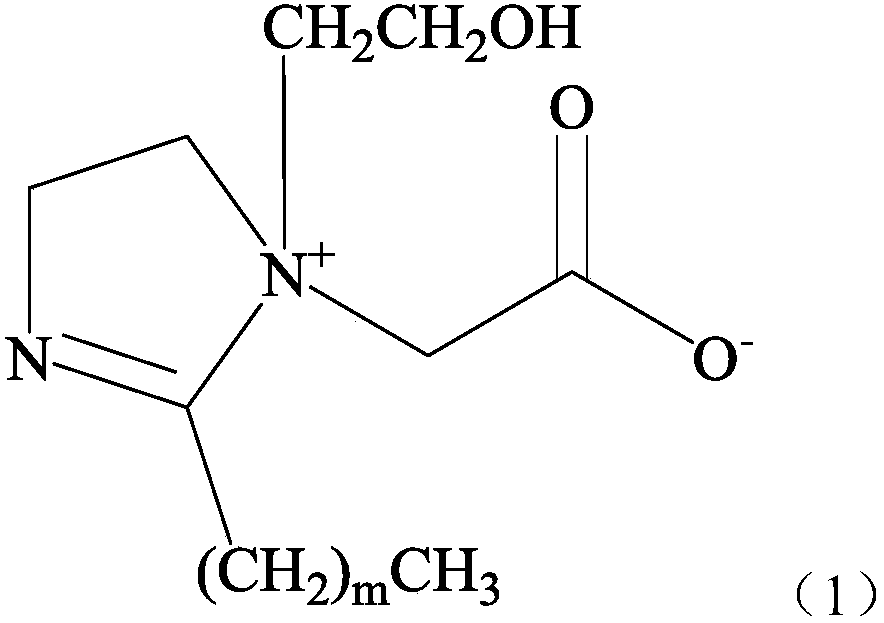

[0056] Add 479 grams of water and 500 grams of concentrated hydrochloric acid in a 1000mL beaker, then add 7 grams of lauryl imidazoline betaine, 5 grams of hydrophilic nano-silica, 1 gram of propargyl alcohol solution (20% wt), 5 grams of aniline Butyrophenone solution (20%wt) and 3 grams of trisodium citrate were stirred evenly to obtain nano foam acid.

Embodiment 2

[0058] Add 474 grams of water and 500 grams of concentrated hydrochloric acid in a 1000mL beaker, then add 7 grams of cocoyl imidazoline betaine, 10 grams of hydrophilic nano-silica, 1 gram of propynyl alcohol solution (20%wt), 5 grams of benzene Aminobutanone solution (20%wt) and 3 grams of trisodium citrate were stirred evenly to obtain nano foam acid.

Embodiment 3

[0060] Add 471 grams of water and 500 grams of concentrated hydrochloric acid in a 1000mL beaker, then add 5 grams of lauryl imidazoline betaine, 5 grams of cocoyl imidazoline betaine, 10 grams of hydrophilic nano-silica, and 1 gram of propynyl alcohol solution (20%wt), 5 grams of anilaminoacetate solution (20%wt) and 3 grams of trisodium citrate were stirred evenly to obtain nano foam acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com