Medium and culture method for fermenting Aspergillus fumigatus to produce fumagillin

A fermentation medium, fumagillin technology, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve problems such as increasing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A seed culture medium for producing fumagillin by Aspergillus fumigatus, each liter of the seed culture medium includes the following components in mass volume ratio: glycerol 22.0~50.0g / L, MgSO 4 ·7H 2 O 0.1~0.5g / L, NaCl 10.0~20.0g / L, KH 2 PO 4 0.1~0.5g / L, FeSO 4 ·7H 2 O 0.013g / L, CuSO 4 ·5H 2 O 0.004g / L, CaCO 3 1~5g / L, peptone 10~30g / L, agar 15~20g / L, the balance is water.

[0026] A fermentation medium for producing fumagillin by fermentation of Aspergillus fumigatus, the seed medium per liter includes the following components in mass-to-volume ratio: 20-50 g / L of glycerol, 1-10 g / L of yeast extract powder, MgSO 4 ·7H 2 O 1~10 g / L, KCl 1~10 g / L, K 2 HPO 4 5~30g / L,FeSO 4 ·7H 2 O 0.013 g / L, corn flour 1~20 g / L, the balance is water. Among them: glycerol, as a carbon source; yeast extract powder, as an organic nitrogen source; corn flour, as a growth factor.

Embodiment 2

[0028] A method for producing fumagillin by Aspergillus fumigatus fermentation, comprising the following steps:

[0029] Step 1. Inoculate the Aspergillus fumigatus in the seed medium to activate the strain, and the pH value of the culture medium is natural; the activation conditions of the strain are: temperature 25-35°C, culture period 6-10 days;

[0030]Step 2: inoculate the monospore suspension prepared by activated strains on the fermentation medium, the pH of the fermentation medium is natural, carry out fermentation culture, and collect the fumagillin in the fermentation broth. Fermentation was carried out by means of shake flask fermentation, the fermentation culture temperature of the shake flask fermentation was 30°C, and the shaker rotation speed was 180 rpm; the glass beads were 6 mm in diameter, and the addition amount was 10; the inoculum volume percentage was 1%, The mass-volume ratio of corn flour is 1~20 g / L, and the liquid volume is 50mL / 250 mL; the whole fer...

Embodiment 3

[0032] A method for producing fumagillin by Aspergillus fumigatus fermentation, comprising the following steps:

[0033] Step 1. Inoculate the Aspergillus fumigatus in the seed medium to activate the strain, and the pH value of the medium is natural; the activation conditions of the strain are: temperature 30°C, culture period 8 days;

[0034] Step 2: inoculate the monospore suspension prepared by activated strains on the fermentation medium, the pH of the fermentation medium is natural, carry out fermentation culture, and collect the fumagillin in the fermentation broth. Fermentation was carried out in a 5 L fermenter, and the fermentation conditions of the 5 L tank were: temperature 30°C, rotation speed 800 rpm, oxygen flux 2 L / min, inoculum volume percentage 1%, corn flour mass volume ratio 1.7 g / L, pH 6.2.

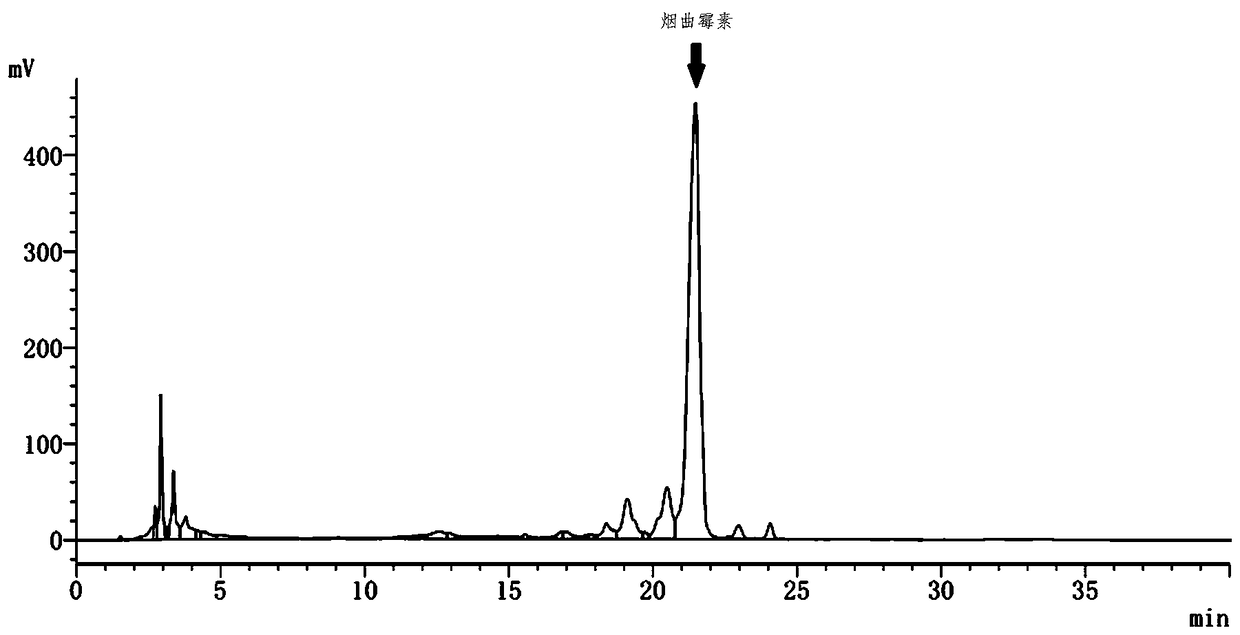

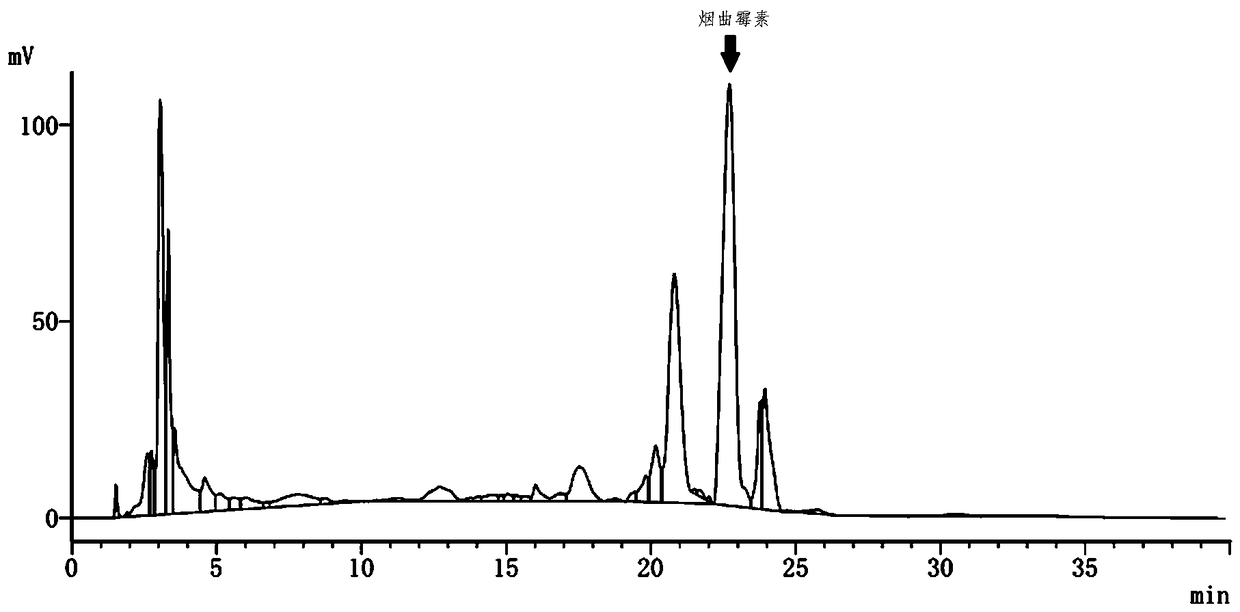

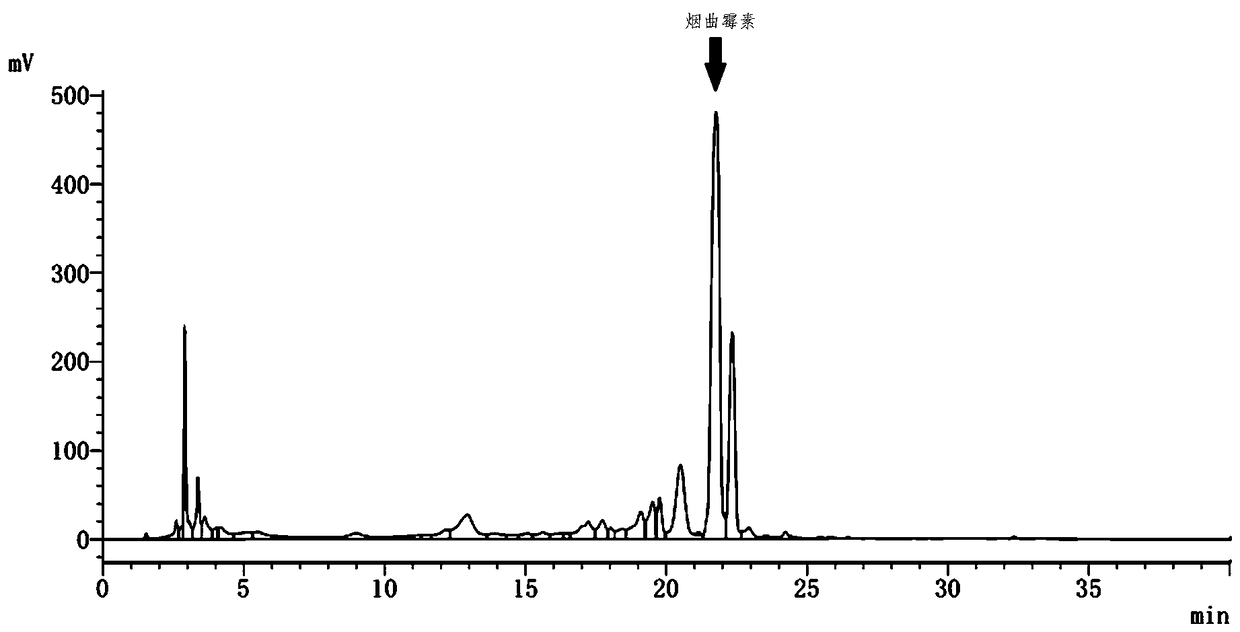

[0035] Using glycerol as a carbon source, the content of fumagillin in 5 L fermenter fermentation culture is 90-150 mg / L, such as figure 1 As shown, through high-per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com