Preparation method of wheat germ anti-oxidation peptides

A technology of wheat germ and antioxidant peptides, which is applied in the field of preparation of wheat germ antioxidant peptides, can solve the problem that wheat germ is not fully utilized, achieve good application value, high protein extraction rate, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

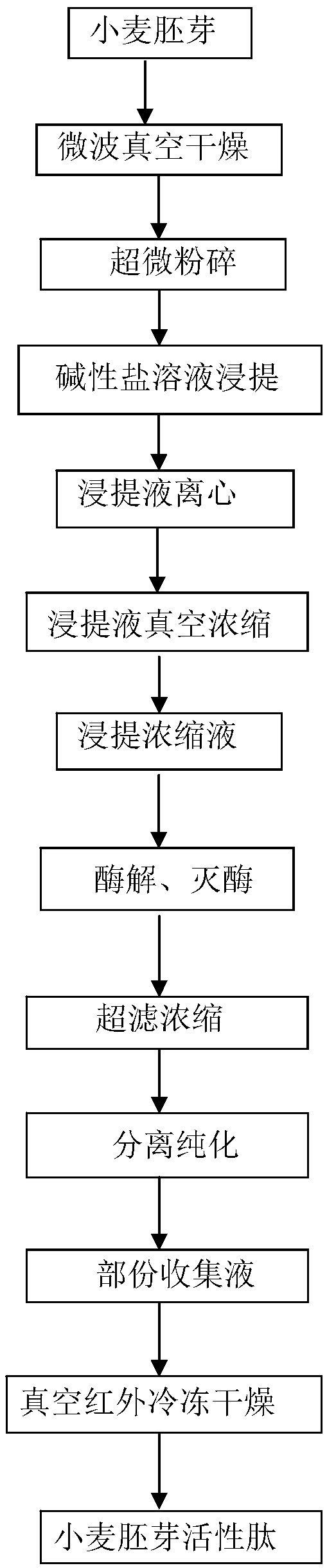

[0028] Such as figure 1 Shown, the preparation method of wheat germ antioxidant peptide of the present invention is specifically as follows:

[0029] (1) Microwave vacuum drying and superfine grinding of wheat germ to obtain wheat germ superfine powder, take 50 g of a sample passed through a 60-mesh sieve, use 0.5 mol / L sodium chloride, pH value 10, and solid-liquid ratio 1:10 , the sample was leached for 60min by an ultrasonic-assisted method, the ultrasonic wave was 40W, leached twice, and the leaching solution was combined to obtain a wheat germ protein solution;

[0030] (2) adopt 10000rpm centrifugal 30min to carry out solid-liquid separation, get supernatant, be wheat germ protein extract;

[0031] (3) Get 900mL of the wheat germ protein extract obtained in step (2) and carry out ultrafiltration concentration, the temperature is 40°C, the operating pressure is 0.1MPa, the ultrafiltration membrane aperture is 200nm, and concentrated to 260mL to obtain the wheat germ prot...

Embodiment 2

[0046] (1) After the wheat germ is subjected to microwave vacuum freeze-drying and superfine pulverization, the wheat germ superfine powder is obtained, and 50 g of a sample of 60 mesh sieves is taken, 0.8mol / L sodium chloride is used, the pH value is 10, and the solid-liquid ratio is 1: 8. The sample was extracted for 100 minutes by the ultrasonic-assisted method, and the ultrasonic wave was 60W, and the extraction was repeated once to obtain the wheat germ protein solution;

[0047] (2) adopt 10000rpm centrifugal 60min to carry out solid-liquid separation, get supernatant, be wheat germ protein extract;

[0048] (3) Get 800mL of the wheat germ protein extract obtained in step (2) and carry out ultrafiltration and concentration, the temperature is 40°C, the operating pressure is 0.7MPa, the ultrafiltration membrane aperture is 10nm, and concentrated to 300mL to obtain the wheat germ protein concentrate;

[0049] (4) Take 50mL of wheat germ protein concentrate, add pepsin at a...

Embodiment 3

[0054] (1) Microwave vacuum drying and superfine grinding of wheat germ to obtain superfine powder of wheat germ, take 100g of sample through a 60-mesh sieve, use 0.2mol / L sodium chloride, pH value 8, solid-liquid ratio 1:5 , the sample was extracted for 120min by an ultrasonic-assisted method, and the ultrasonic wave was 30W, and the extraction was repeated once to obtain a wheat germ protein solution;

[0055] (2) adopt 10000rpm centrifugal 60min to carry out solid-liquid separation, get supernatant, be wheat germ protein extract;

[0056] (3) Get 950mL of the wheat germ protein extract obtained in step (2) and carry out ultrafiltration concentration, the temperature is 40°C, the operating pressure is 0.1MPa, the ultrafiltration membrane aperture is 200nm, and concentrated to 500mL to obtain the wheat germ protein concentrate;

[0057] (4) adding 0.1% pepsin to the wheat germ protein concentrate, adjusting the pH value to 1.0, incubating at 30°C for 360 minutes, boiling at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com