Fabric coating technology

A coating process and fabric technology, applied in textiles and papermaking, etc., can solve the problems of increasing the surface roughness of the nip roll, the surface of the nip roll is not smooth enough, and the base fabric is wrinkled. The effect of soft hand and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Fabric coating process, comprising the following steps:

[0036] Step 1, preparation of coating agent ingredients: weigh 100kg of water, 100kg of polysiloxane, 10kg of polyurethane, 5kg of polyvinyl acetate, 1kg of accelerator, and 5kg of mica flakes by mass.

[0037] Step 2, preparation of coating agent: Grind mica sheet into mica powder, and filter with 150 mesh filter screen; Place the water, polysiloxane, polyurethane, polyvinyl acetate and accelerator in step 1 in the reaction kettle, and After stirring for 5 minutes under the action of a spiral stirring rod, add mica powder and continue stirring for 15 minutes to obtain a coating agent.

[0038] Step 3, transfer paper coating: use a floating knife to evenly coat the coating agent in step 2 on the upper surface of the transfer paper.

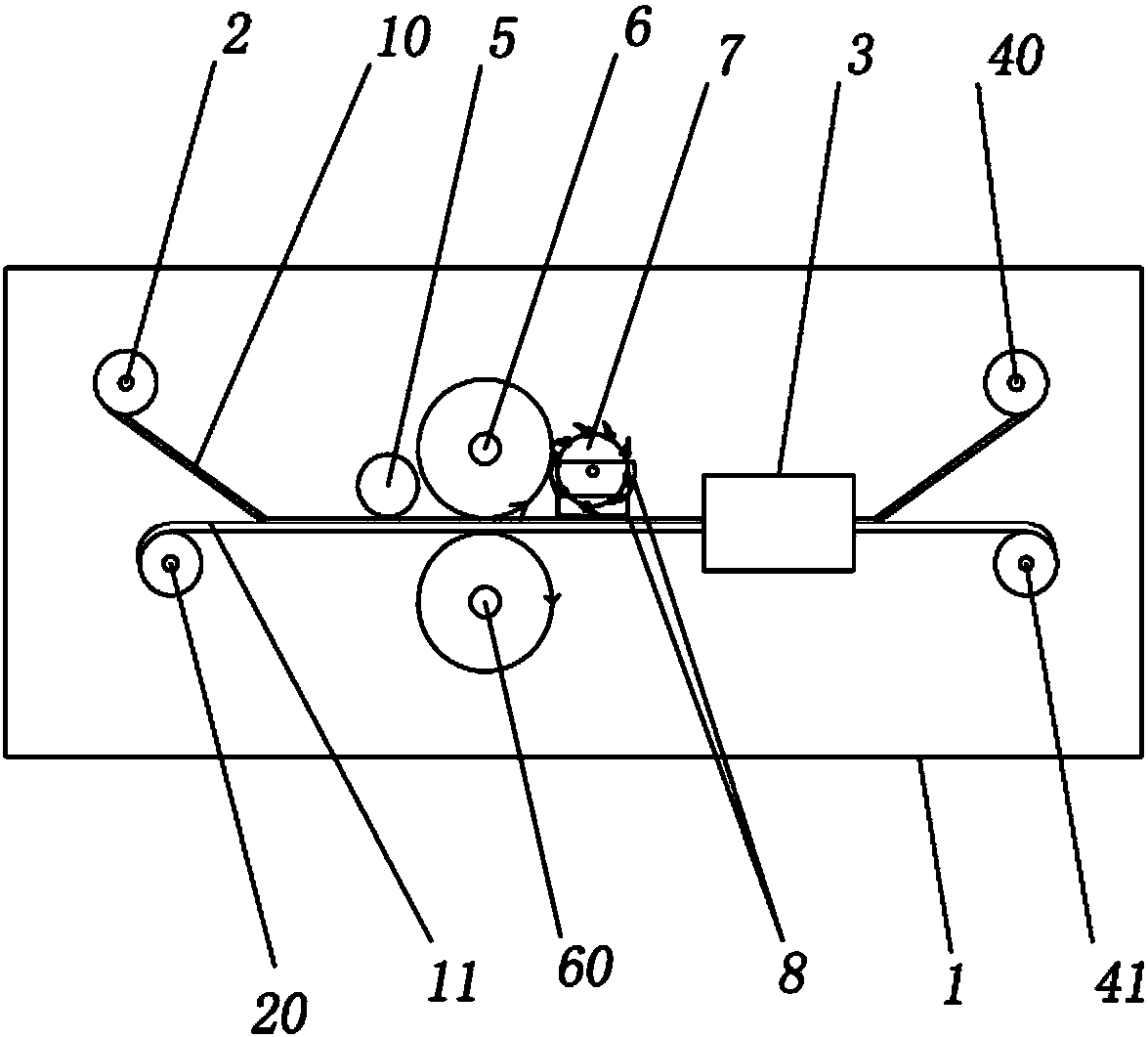

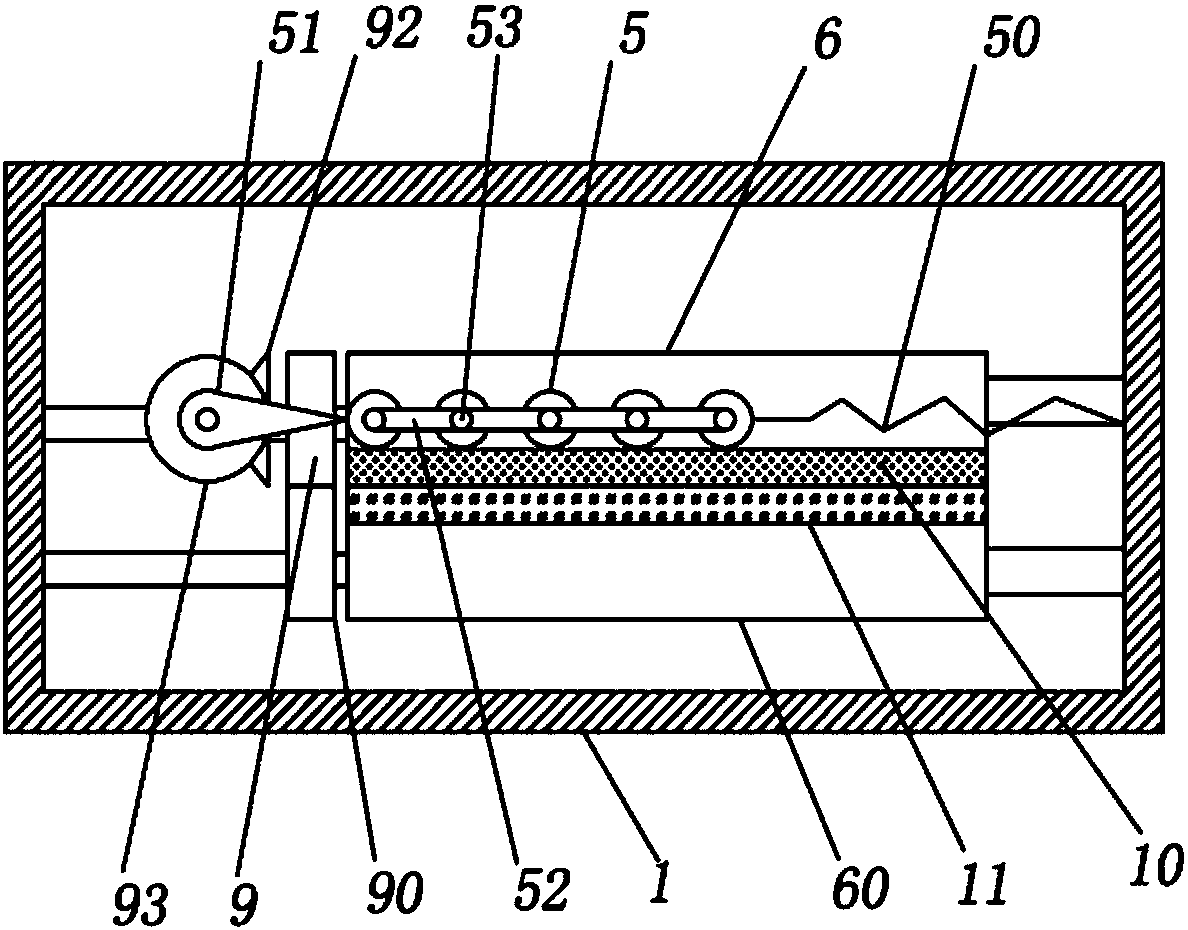

[0039] Step 4, the base cloth is leveled: as figure 1 As shown, the base cloth and the transfer paper in step 3 are conveyed by the base cloth feeding roller and the transfer paper...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] In step 1, preparation of coating agent ingredients: weighing 100kg of water, 150kg of polysiloxane, 15kg of polyurethane, 10kg of polyvinyl acetate, 5kg of accelerator, and 8kg of mica flakes by mass.

[0050] In step 2, preparation of coating agent: Grinding mica flakes into mica powder, and filtering with a 200-mesh filter screen; placing water, polysiloxane, polyurethane, polyvinyl acetate and accelerator in step 1 in a reaction kettle, and After stirring for 8 minutes under the action of a spiral stirring rod, add mica powder and continue stirring for 20 minutes to obtain a coating agent.

[0051] In step five, the pressing force of the upper roller and the lower roller to the base cloth is 12N.

[0052] The drying temperature in step seven is 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com