Atomic bonding-based on-chip microflow cooling GaN crystal tube and manufacturing method thereof

A technology of transistors and gallium nitride, which is applied in the direction of electrical solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as limiting the performance of gallium nitride devices, low thermal conductivity, and degradation of device performance and reliability. Achieve the effect of improving high-efficiency heat dissipation characteristics and high-efficiency heat dissipation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

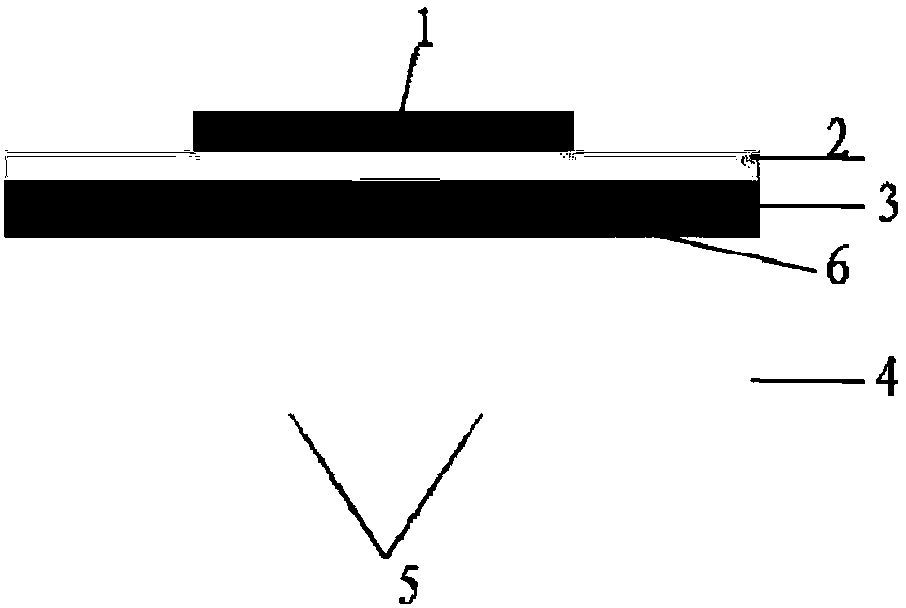

[0034] A method for designing and manufacturing a near-junction microflow embedded gallium nitride transistor with high efficiency heat dissipation, including:

[0035] 1) Complete the conventional front-side process of gallium nitride transistors to obtain gallium nitride transistors, the substrate of which is made of SiC material, the size of the active region is 60*125um, and it is a two-gate structure;

[0036] 2) In-chip microfluidic channel preparation based on atomic bonding;

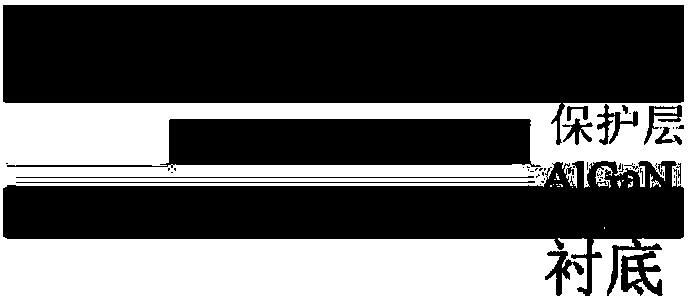

[0037] ① Coating a layer of silicon oxide dielectric protective layer on the front of the completed gallium nitride transistor to protect the functional area, and using bonding technology to bond the front of the transistor to the temporary carrier;

[0038] ② Put the gallium nitride transistor containing the temporary carrier into the grinding machine, and grind and thin the SiC substrate to a thickness of 15 microns;

[0039] ③ Coat one side of a new SiC substrate with a silicon oxide dielectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com