A sb for lithium-sulfur battery separator 2 the se 3 Preparation method of composite material

A composite material, lithium-sulfur battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as polysulfide adsorption, and achieve the effects of high production yield, improved utilization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention will be further described below in conjunction with specific embodiment:

[0029] Sb used in the present invention 2 Se 3 , pvp and GO suspensions were all purchased from the market.

[0030] The first step is to prepare Sb 2 Se 3 -pvp-rGO:

[0031] Weigh Sb 2 Se 3 Powder 0.20g, weigh 0.05g pvp, pour it into a beaker, add 49.75mL deionized water, and configure it as a mass fraction of 0.5% Sb 2 Se 3 -pvp suspension, using a magnetic stirrer to stir for 1h, then Sb 2 Se 3 - The pvp suspension was sonicated on an ultrasonic cell pulverizer for 30 minutes to disperse it evenly. Then mixed with graphene oxide aqueous solution, according to Sb 2 Se 3 -The mass ratio of pvp to graphene oxide is 1:1, measure 125mL graphene oxide aqueous phase dispersion (concentration is 2mg / mL), prepare Sb 2 Se 3 - The mixed dispersion of pvp-GO was magnetically stirred for 1 hour, then sonicated for 20 minutes using an ultrasonic cell disruptor, and then l...

Embodiment 2

[0039] Others are the same as embodiment 1, and the difference is the first step Sb 2 Se 3 - The mass ratio of pvp to graphene oxide is 1:1.5, and the dosage of hydrazine hydrate is 37.5 μL.

Embodiment 3

[0041] Others are the same as embodiment 1, and the difference is the first step Sb 2 Se 3 - The mass ratio of pvp to graphene oxide is 1:2, and the dosage of hydrazine hydrate is 50 μL.

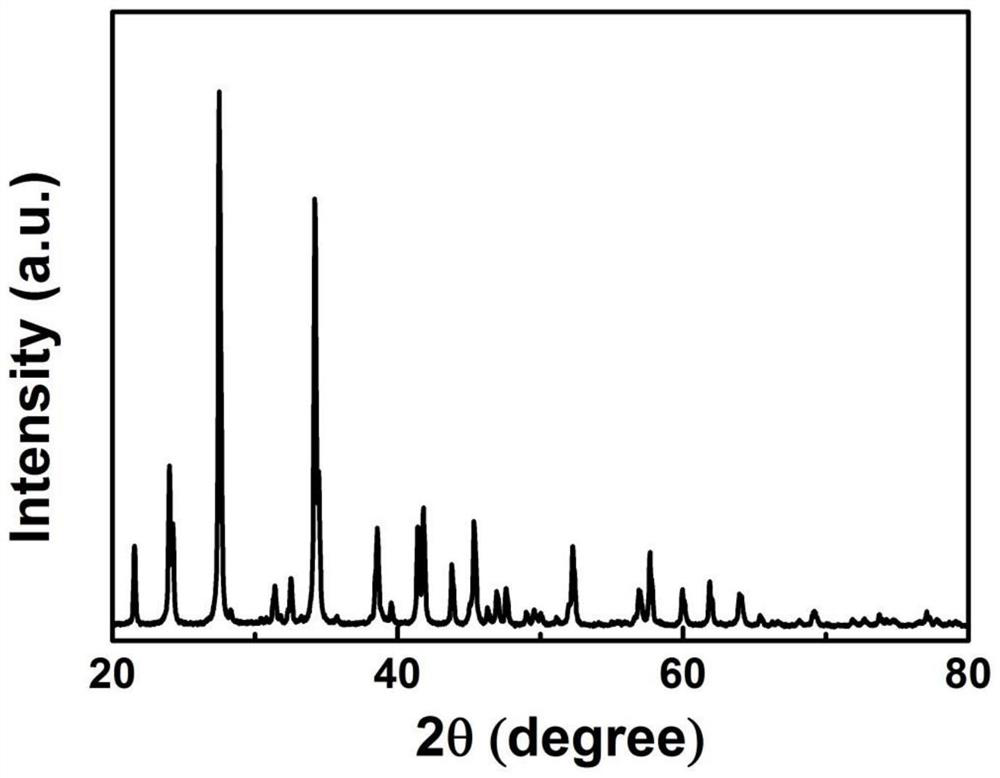

[0042] figure 1 For the prepared Sb of Example 1 2 Se 3 - XRD pattern of pvp-rGO material. It can be seen from the figure that there is an obvious graphene peak at 23°, proving that rGO and Sb 2 Se 3 -pvp materials compound very well.

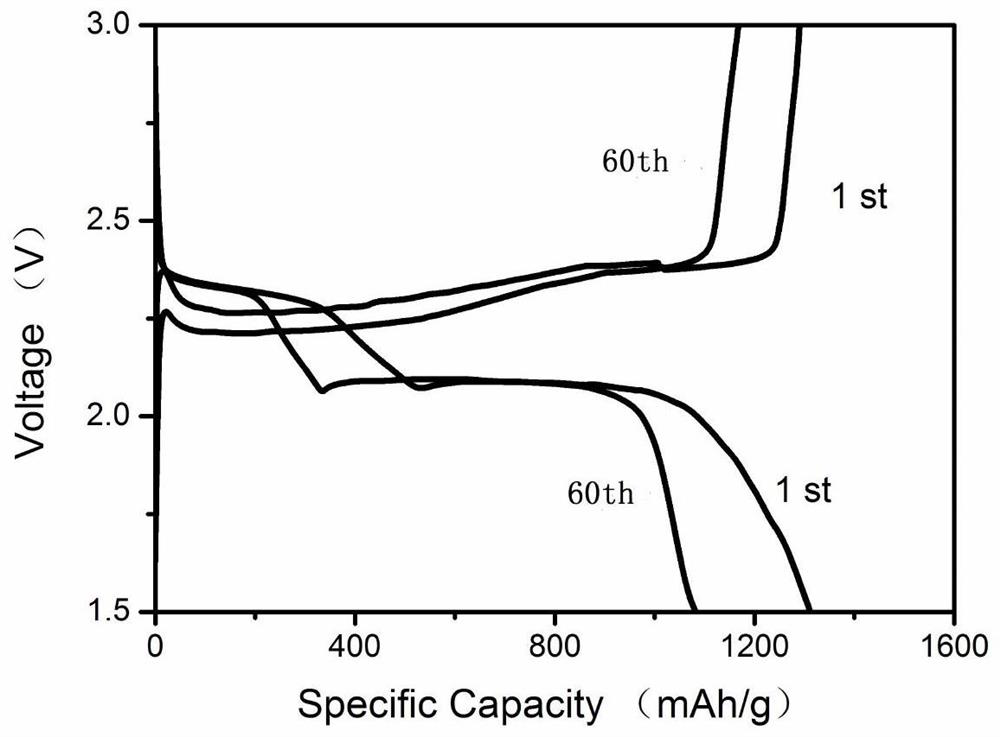

[0043] figure 2 For the prepared Sb of Example 1 2 Se 3 - The first charge-discharge curve of pvp-rGO material as a separator at 0.1C. The test equipment uses Xinwei BTS-2000, and the test is carried out at a constant room temperature (25°C). The constant current discharge voltage is set to 3.0V, and the charging voltage is set to 1.5V, so that the prepared lithium-sulfur battery can work in the voltage range of 1.5-3.0V. It can be seen from the figure that the charge and discharge specific capacities of the 60th cycle can still reach 1168 and 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com