Incremental freeze concentration equipment with double-sandwich structure and freeze concentration method

A freeze-concentration, double-interlayer technology, applied in chemical instruments and methods, solution crystallization, crystallization separation, etc., can solve the problems of increasing solute entrainment, affecting production efficiency, lack of scientific treatment methods in the later thawing stage, etc., to optimize the process. Condition, Effective Concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: Progressive freeze-concentration equipment with double sandwich structure

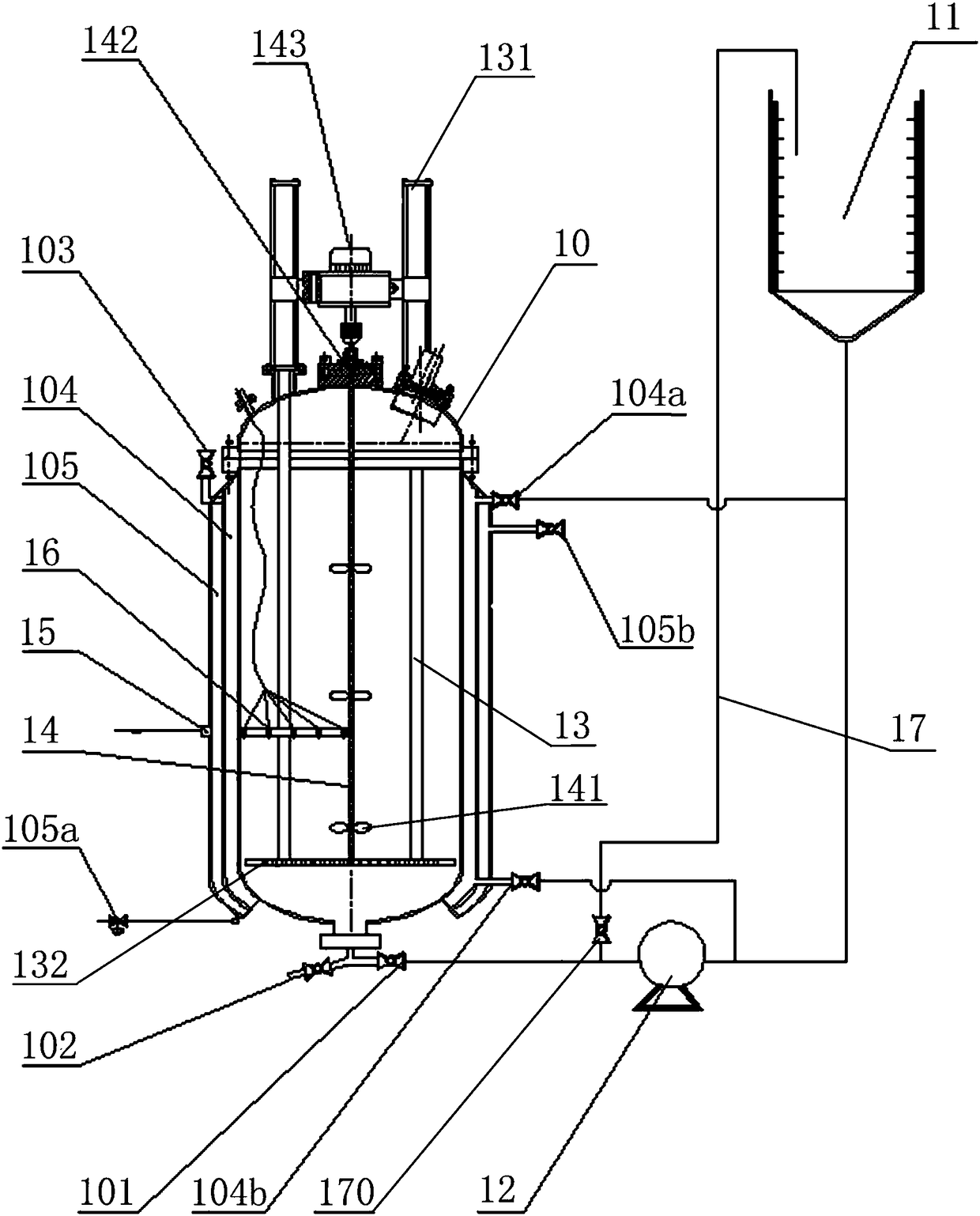

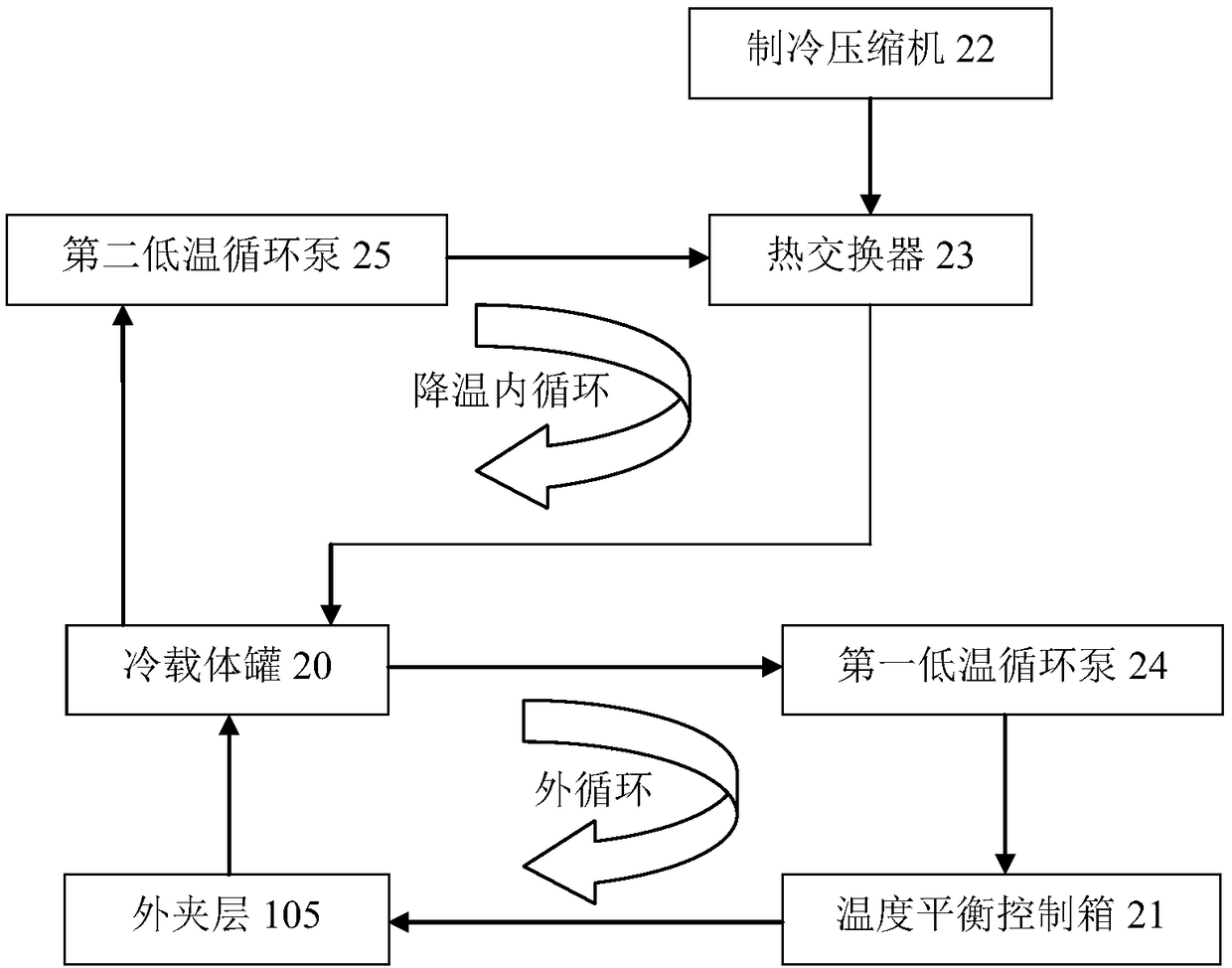

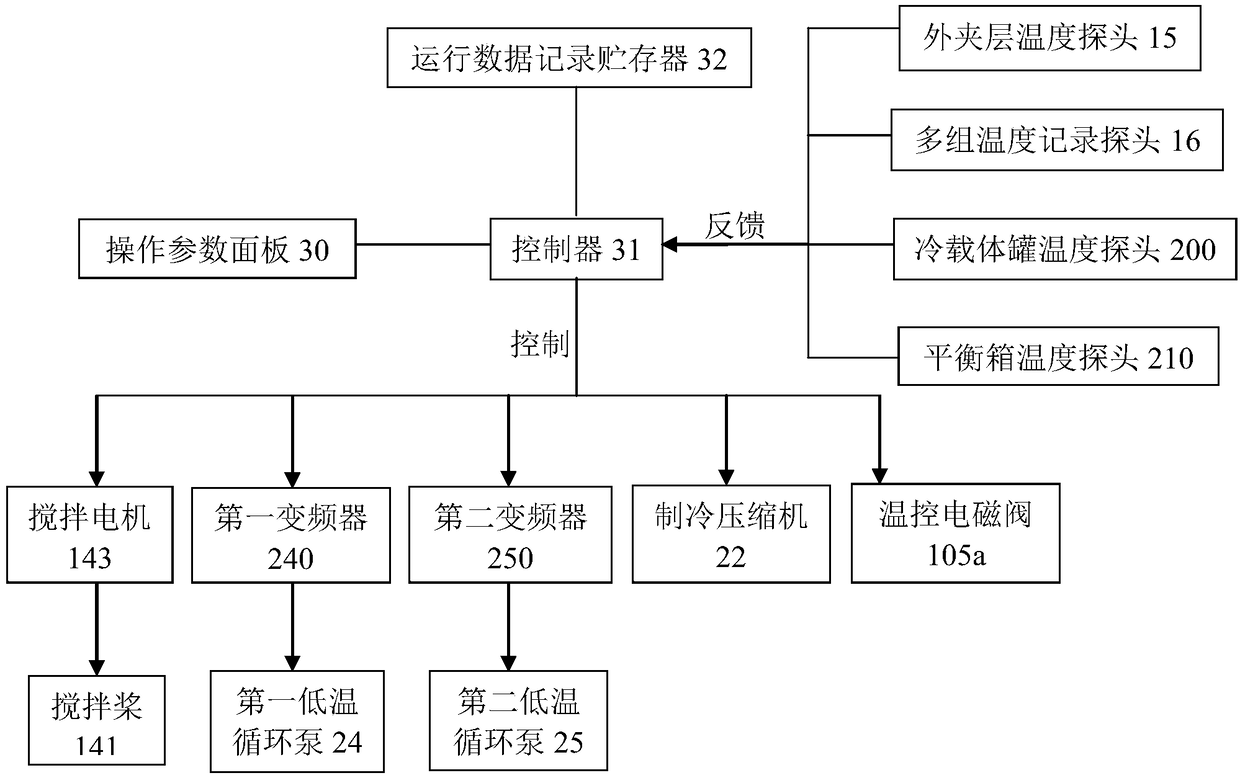

[0053] Please also see Figure 1~3 , figure 1 It is a schematic diagram of the structure of the crystallization concentration unit, figure 2 It is a schematic diagram of the connection of the cold carrier temperature control unit, image 3 It is a schematic diagram of the connection control between the parameter control and the automatic recording unit.

[0054] The progressive freezing and concentrating equipment with a double sandwich structure of the present invention includes a crystallization and concentration unit, a cold carrier temperature control unit, and a parameter control and automatic recording unit.

[0055] Such as figure 1 As shown, the crystallization concentration unit includes a crystallization concentration tank 10 , a heat preservation tank 11 , a cryogenic pump 12 , a pneumatic lifting device 13 , a stirring device 14 , an outer interlayer temperature ...

Embodiment 2

[0074] Embodiment 2: freeze concentration method

[0075] Use the progressive freeze concentration equipment of double sandwich structure of the present invention to carry out the operation method of freeze concentration as follows:

[0076] S1: Measure the freezing point and supercooling point of the feed liquid to be concentrated.

[0077] S2: setting the temperature range of the first stage, cleaning the crystallization concentration tank 10, the specific steps are as follows:

[0078] Start the power supply of the equipment, and use the operating parameter panel 30 to respectively set the ranges of the temperature of the cold carrier tank, the temperature of the temperature balance control box and the temperature of the outer interlayer. Among them, the lower limit of the temperature of the cold carrier tank is the lowest, the upper limit of the temperature of the cold carrier tank, the lower limit of the temperature of the temperature balance control box and the lower ...

Embodiment 3

[0101] Embodiment 3: to the freezing concentration application of fruit vinegar

[0102] The progressive freeze-concentration equipment and the concentration method of the double sandwich structure of the present invention are applied to the freeze-concentration of the clear and transparent food material liquid, specifically to the freeze-concentration of the fruit vinegar stock solution.

[0103] The fruit vinegar stoste to be concentrated is a clear transparent liquid, and its weight is 50.6kg, and initial soluble solid content is 7.7%, and total acid (calculated as acetic acid) is 1.87%, and freezing point is-2.1 ℃, and supercooling point is-3.3 ℃ .

[0104] The specific process operating parameters set in stages of freeze concentration and thawing are shown in Table 1.

[0105] Table 1 Process operating parameters of fruit vinegar freeze-concentration set in stages

[0106]

[0107]

[0108] The first stage of freeze-concentration in Table 1 is the stage in which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com