Sulfydryl modified charcoal based on agricultural wastes, preparation method and application thereof

A technology of agricultural waste and biochar, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as non-environmental protection, complicated process, etc., achieve short adsorption time, simple preparation process, and good social benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

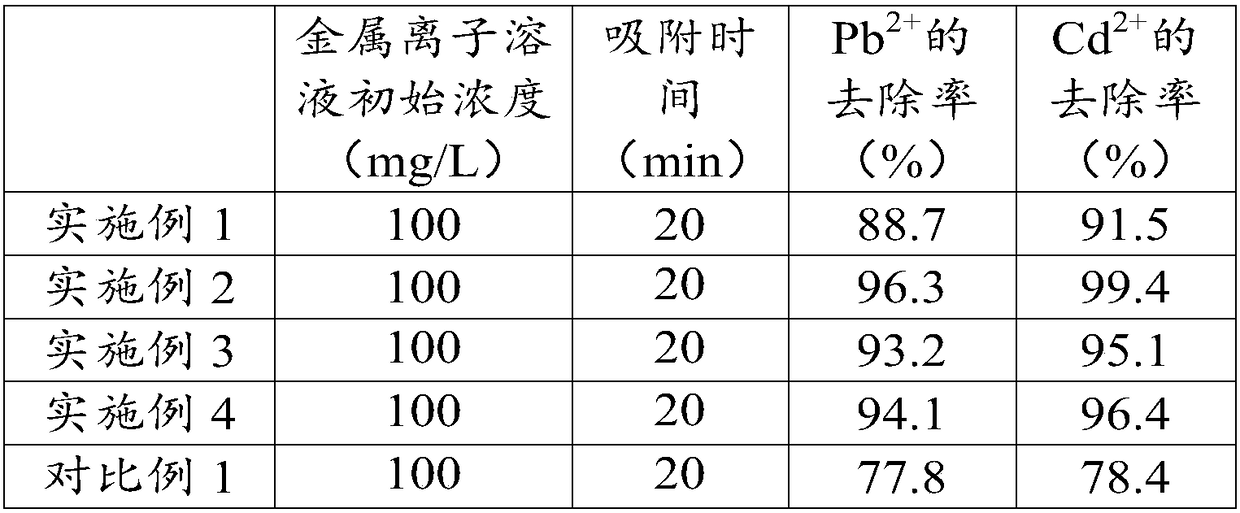

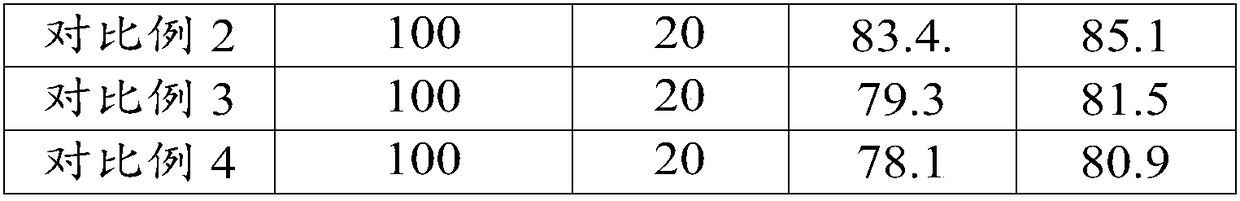

Examples

preparation example Construction

[0016] A method for preparing agricultural waste-based mercapto-modified biochar provided by an embodiment of the present invention includes:

[0017] Take an appropriate amount of agricultural waste, crush it, dry it and grind it, so that the agricultural waste is granular. Under the condition of anaerobic or anoxic, 300-700°C, the agricultural waste particles are heated to obtain biochar. The product is a crude product. In order to obtain biochar with uniform particles and easy processing, the biochar is passed through a 50-70 mesh sieve, and the biochar under the sieve is taken as the first sieve, and is set aside. In the present invention, agricultural waste mainly includes fruit skins, peanut skins, waste leaves and the like.

[0018] Take the first sieve, add concentrated nitric acid, stir magnetically at 40-70°C for 24-48 hours to oxidize the biochar under the sieve with concentrated nitric acid, filter the mixed solution with water, wash the filter residue with water,...

Embodiment 1

[0027] This example provides a mercapto-modified biochar based on agricultural waste, which is mainly made by the following steps:

[0028] Take an appropriate amount of agricultural waste, crush it, dry it and grind it, so that the agricultural waste is granular. Under the condition of limited oxygen and 300°C, the agricultural waste particles were heated to obtain biochar. The biochar is passed through a 50-mesh sieve, and the biochar under the sieve is taken as the first sieve.

[0029] Take the first sieve, add concentrated nitric acid, stir magnetically at 40°C for 24 hours to oxidize the biochar under the sieve with concentrated nitric acid, filter the mixture with suction, wash the filter residue with water, and then dry to obtain oxidized biochar. The mass ratio of the first undersize to concentrated nitric acid is 1:2. Pass the oxidized biochar through a 70-mesh sieve, take the oxidized biochar under the sieve as the second sieve, and save it for future use.

[003...

Embodiment 2

[0032] This example provides a mercapto-modified biochar based on agricultural waste, which is mainly made by the following steps:

[0033] Take an appropriate amount of agricultural waste, crush it, dry it and grind it, so that the agricultural waste is granular. Under the condition of limited oxygen and 700°C, the agricultural waste particles were heated to obtain biochar. The biochar is passed through a 70-mesh sieve, and the biochar under the sieve is taken as the first sieve.

[0034] Take the first sieve, add concentrated nitric acid, stir magnetically at 70°C for 48 hours to oxidize the biochar under the sieve with concentrated nitric acid, filter the mixed solution with suction, wash the filter residue with water, and then dry to obtain oxidized biochar. The mass ratio of the first undersize to concentrated nitric acid is 1:5. Pass the oxidized biochar through a 90-mesh sieve, take the oxidized biochar under the sieve as the second sieve, and save it for future use. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com