Biochemical treatment sewage modification technology

A biochemical treatment and sewage technology, applied in biological water/sewage treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of large area of secondary sedimentation tank and filtration equipment, increase of suspended solids in effluent, poor effluent quality, etc. Achieve the effect of reducing floor space, reducing sludge treatment costs, and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

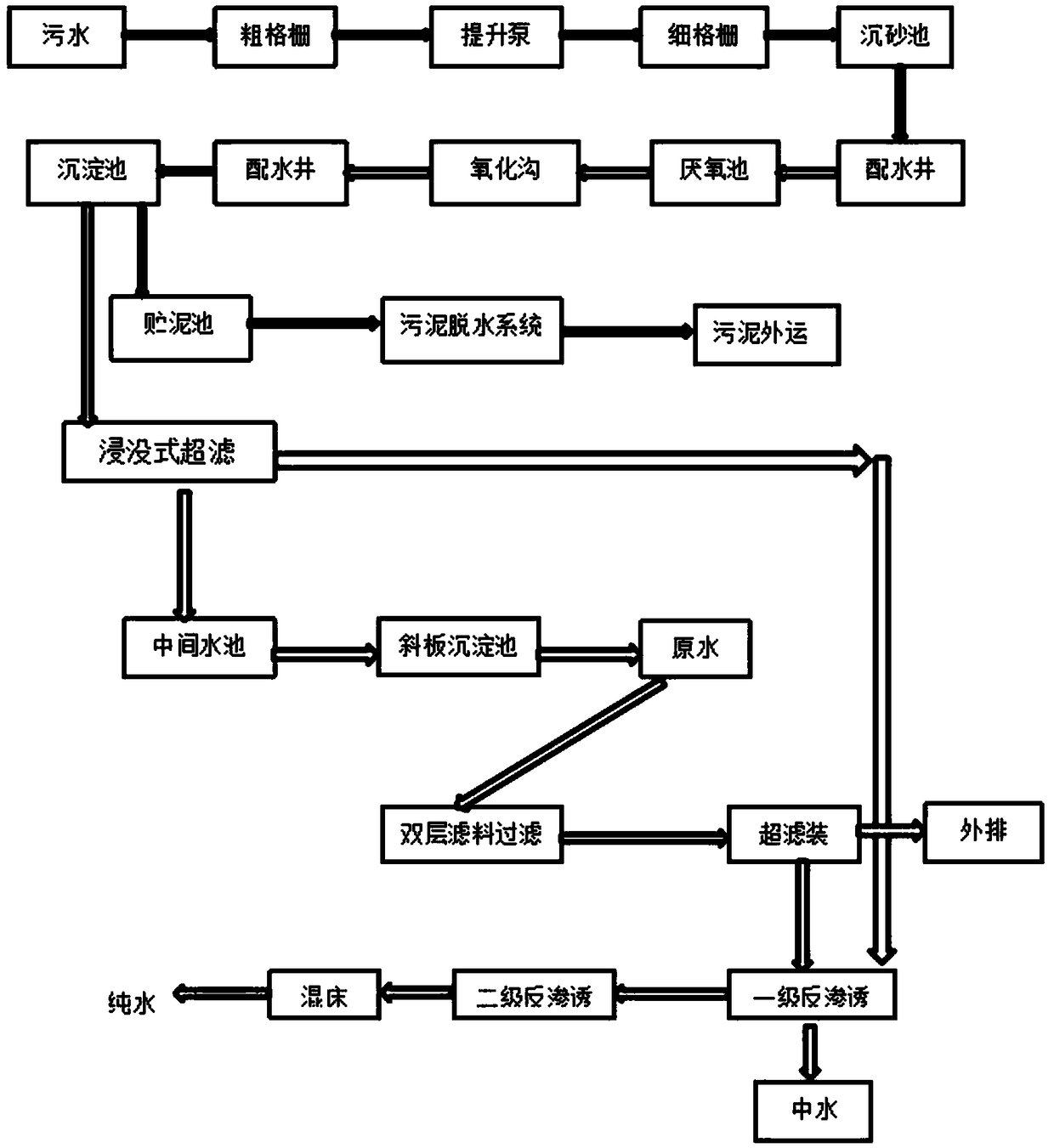

[0040] A biochemical sewage treatment transformation process, comprising the following steps:

[0041] (1) Sewage pretreatment

[0042] First, the sewage enters the coarse screen through the pipeline, and then it is lifted into the fine screen through the lifting pump room to initially filter out the large-volume waste;

[0043] (2) Precipitation removal

[0044] The pretreated sewage is precipitated to remove impurities through a cyclone grit chamber, and the precipitation time is 40 minutes;

[0045] (3) Biochemical treatment

[0046] The sewage after the sedimentation is removed enters the biochemical treatment ditch through the water distribution well for biochemical treatment, and the biochemical treatment ditch is an anaerobic pond and an oxidation ditch;

[0047] (4) Precipitation treatment

[0048] Then the biochemically treated sewage enters the secondary settling tank through the water distribution well, the sludge in the secondary settling tank enters the mud st...

Embodiment 3

[0054] A biochemical sewage treatment transformation process, comprising the following steps:

[0055] (1) Sewage pretreatment

[0056] First, the sewage enters the coarse screen through the pipeline, and then it is lifted into the fine screen through the lifting pump room to initially filter out the large-volume waste;

[0057] (2) Precipitation removal

[0058] The pretreated sewage is precipitated to remove impurities through a cyclone grit chamber, and the precipitation time is 50 minutes;

[0059] (3) Biochemical treatment

[0060] The sewage after the sedimentation is removed enters the biochemical treatment ditch through the water distribution well for biochemical treatment, and the biochemical treatment ditch is an anaerobic pond and an oxidation ditch;

[0061] (4) Precipitation treatment

[0062] Then the biochemically treated sewage enters the secondary settling tank through the water distribution well, the sludge in the secondary settling tank enters the mud st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com