A kind of porous lightweight steel slag concrete that can be quickly planted and its preparation method

A light-weight steel and concrete technology, applied in botany equipment and methods, planting substrates, ceramic products, etc., can solve the problems of reduced strength, environmental pollution, etc., achieve reduced shrinkage, facilitate plant growth, and enhance slump-preserving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

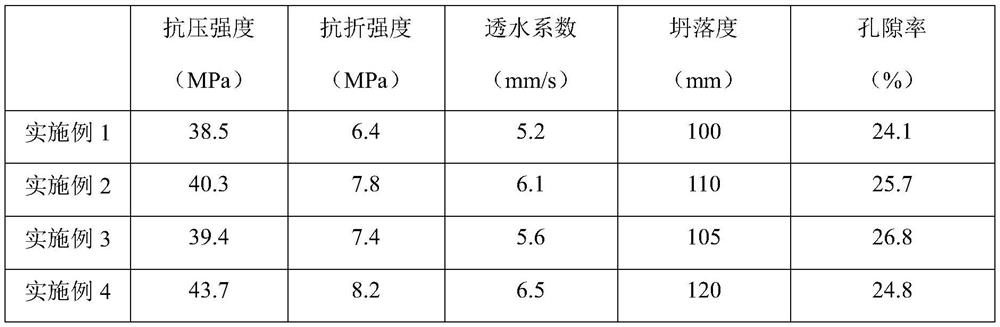

Examples

Embodiment 1

[0030] (1) Raw material composition

[0031] In this embodiment, the porous lightweight steel slag concrete that can be quickly planted has the following composition by weight:

[0032] 100 parts of steel slag coarse aggregate, 70 parts of cement, 40 parts of water, 0.45 parts of water reducer, 4 parts of gypsum, 7 parts of steel slag powder, 4 parts of slag, 0.4 parts of urea, 0.6 parts of magnesium ammonium phosphate, and 0.5 parts of vermiculite.

[0033] The particle size of the steel slag coarse aggregate is 10-25mm.

[0034] The water mentioned is the mixing water that complies with the industry standard JGJ63-2006 "Water for Concrete".

[0035] The cement is Portland cement with a strength grade of 42.5.

[0036] The water reducer is a polycarboxylate water reducer, and the solid content of the polycarboxylate water reducer is 39-41%.

[0037] The particle size of the steel slag fine powder is 30 μm-40 μm. The steel slag fine powder is made of converter steel slag o...

Embodiment 2

[0049] (1) Raw material composition

[0050] In this embodiment, the porous lightweight steel slag concrete that can be quickly planted has the following composition by weight:

[0051] Steel slag coarse aggregate 150 parts, cement 80 parts, water 45 parts, water reducing agent 0.55 parts, gypsum 6 parts, steel slag powder 9 parts, slag 5 parts, urea 0.4 parts, magnesium ammonium phosphate 0.4 parts, vermiculite 0.6 parts

[0052] Other technical indexes are with embodiment 1.

[0053] (2) Preparation method

[0054] (1) Prepare materials according to the ratio of step (1).

[0055] (2) Add cement, water, and water reducing agent into the mixer and stir for 1.5 minutes.

[0056] (3) Add steel slag coarse aggregate under stirring state, and then continue stirring for 1 min.

[0057] (4) Add the pre-mixed uniform gelling material and vermiculite, and stir for 2 minutes to prepare a slurry.

[0058] (5) Pour the slurry into the mold, and put it into the curing room for stand...

Embodiment 3

[0063] (1) Raw material composition

[0064] In this embodiment, the porous lightweight steel slag concrete that can be quickly planted has the following composition by weight:

[0065] 125 parts of steel slag coarse aggregate, 75 parts of cement, 43 parts of water, 0.5 parts of water reducer, 5 parts of gypsum, 8 parts of steel slag powder, 4 parts of slag, 0.4 parts of urea, 0.5 parts of ammonium magnesium phosphate, and 0.55 parts of vermiculite.

[0066] Other technical indexes are with embodiment 1.

[0067] (2) Preparation method

[0068] (1) Prepare materials according to the ratio of step (1).

[0069] (2) Add cement, water and water reducing agent into the mixer and stir for 2 minutes.

[0070] (3) Add steel slag coarse aggregate while stirring, and then continue stirring for 1.5 minutes.

[0071] (4) Add the cementitious material and vermiculite that have been uniformly mixed in advance, and stir for 2.5 minutes to prepare a slurry.

[0072] (5) Pour the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com