A method for surface treatment of AGM start-stop negative electrode grid

A surface treatment and negative plate technology, applied in the direction of anodic oxidation, battery electrodes, electrode carriers/collectors, etc., can solve the problems of adverse effects on charge acceptance, improve static and dynamic charge and discharge capabilities and start-stop durable cycle life, The effect of reducing the current density and increasing the real surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (A1) Add 11.384Kg of lithium phosphate dihydrate to a container with a density of ρ=1.28g / mL and a volume of 1m 3 Put the sulfuric acid solution in a 1# plastic container, stir well until all the solids are dissolved, and then put the 100Kg negative electrode continuous punching grid into a roll and place it in the above solution for anodic polarization, and the polarization current density is 0.25A / cm 2 , the polarization time is 3.5h;

[0033] (B1) Add 11.641Kg of aniline to a container with a density of ρ=1.28g / mL and a volume of 1m 3 In the 2# plastic container of sulfuric acid solution, fully stir until the aniline is completely dissolved, and then put the negative electrode continuous punching grid after step (A1) for anodic polarization into the above solution for full contact and soaking reaction, and control the temperature in a water bath 45°C, soaking time is 10h, make contact reaction between anodic polarized continuous flushing negative electrode grid surf...

comparative example 1

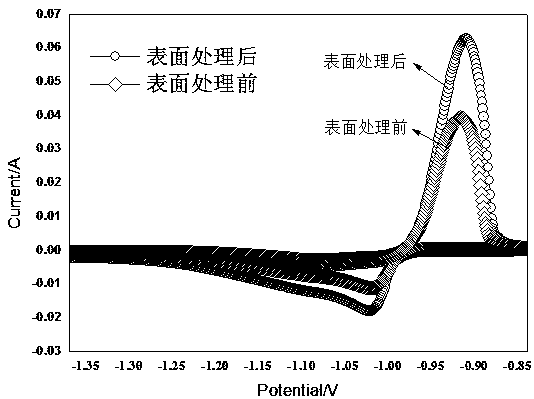

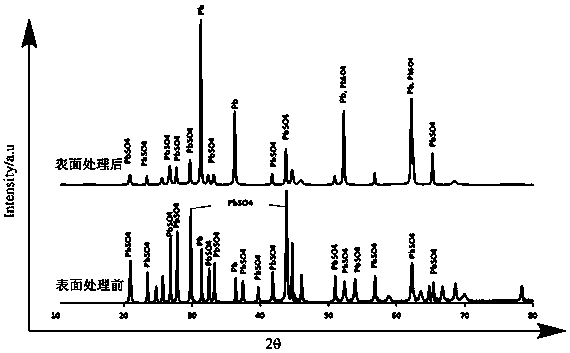

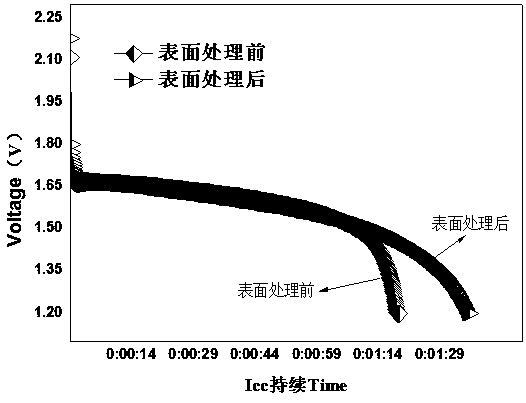

[0037] The negative electrode plate prepared by using the above-mentioned special treatment on the surface of the negative electrode grid is cured and dried according to the normal production process. The electrochemical performance test and microscopic morphology comparison results of the negative electrode plate are as follows: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 shown.

[0038] The negative electrode plate was prepared according to the method described in Example 1, and the processes of curing and drying, encapsulation, assembly, and chemical formation were carried out according to the normal production process, and the start-stop battery of the corresponding type was manufactured to test the low-temperature cold start performance at -18°C, and the dynamic charge acceptance. Capacity, start-stop life, the test standard is carried out in accordance with GBT 2666-2016 start-stop lead-acid battery technical conditions, the results are as foll...

Embodiment 2

[0040] (X1) Add 11.392Kg of lithium phosphate dihydrate to a container with a density of ρ=1.28g / mL and a volume of 1m 3 Put the sulfuric acid solution in a 1# plastic container, stir well until all the solids are dissolved, and then put the 100Kg negative electrode continuous punching grid into a roll and place it in the above solution for anodic polarization, and the polarization current density is 0.27A / cm 2 , the polarization time is 4h;

[0041] (X2) Add 11.72Kg of aniline in advance to a container with a density of ρ=1.28g / mL and a volume of 1m 3 In the 2# plastic container of the sulfuric acid solution, fully stir until the aniline is completely dissolved, and then put the negative electrode continuous punching grid after the anodization in the step (X1) into the above solution for full contact and soaking reaction, and the water bath controls the temperature 50℃, immersion time is 8.5h, make contact reaction between anodic polarized continuous flushing negative electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com