Implant conveying system

A delivery system and implant technology, applied in the field of implant delivery system, can solve the problems of inability to adjust the release position, unsatisfactory, the need to adjust the distal position of the outer sheath tube, the position deviation of the lumen stent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

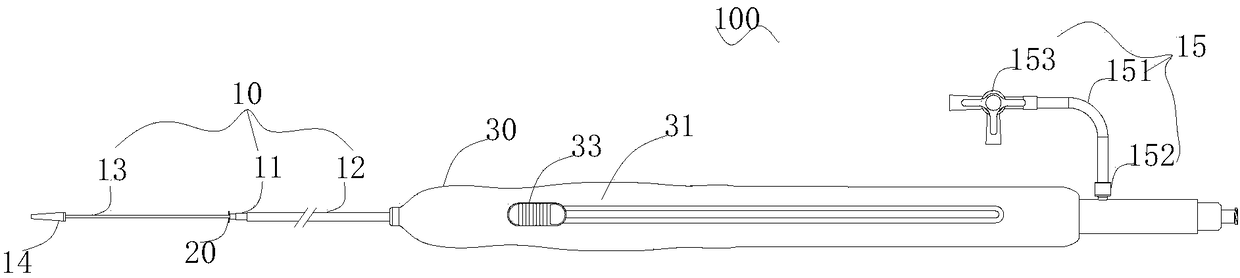

[0050] See figure 1 , the delivery system 100 provided in Embodiment 1 is used to deliver the implant to the lesion in the lumen of the human body. The delivery system 100 includes a tube body 10 , a hooking unit 20 , and a handle including a handle shell 30 and a slider 33 .

[0051] The handle housing 30 includes a first housing 31 and a second housing (not shown in the figure) arranged axially symmetrically. The number of sliders 33 is two. The two sliders 33 are respectively disposed on the first housing 31 and the second housing of the handle housing 30 and are symmetrical to each other.

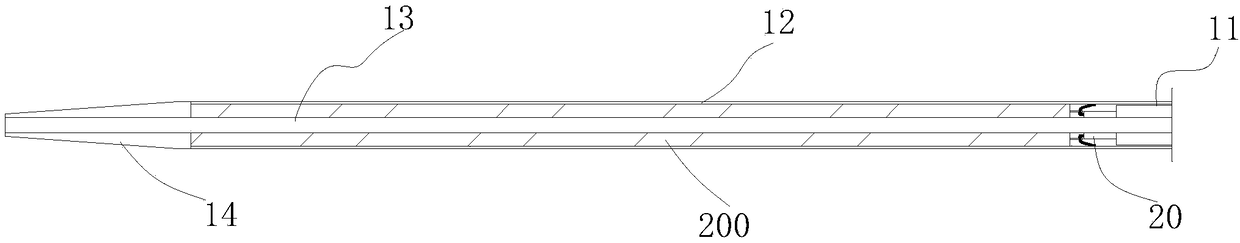

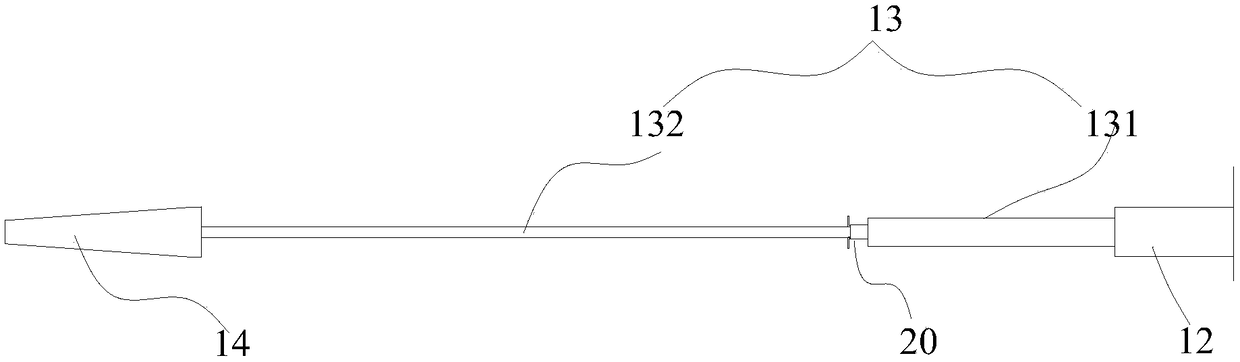

[0052] Please also refer to Figure 2a , in this embodiment, the implant is a lumen stent 200 . The tube body 10 includes a hollow inner sheath tube 11 axially penetrating the handle shell 30, a hollow inner sheath core tube 13 penetrating through the inner sheath tube 11 and having a distal end protruding from the inner sheath tube 11, and is movably sleeved on the inner sheath tub...

Embodiment 2

[0091] The structure of the endoluminal stent delivery system provided in this embodiment is basically the same as that of the endoluminal stent delivery system 100 provided in the first embodiment. The difference is that, in this embodiment, each hooking piece has a U-shaped structure formed by double-strand wires.

[0092] Specifically, see Figure 10a , in this embodiment, the hooking unit includes a hollow tubular tightening member and three hooking members connected to the tightening member. The hooking part has a fixing part connected with the hoop part and a deformation part connected with the fixing part. Each hook is composed of two straight rods and an arc rod connected between the two straight rods.

[0093] Please also see Figure 10b , the radial distance H between the two straight rods ranges from 0.05 to 10 mm. As a result, the reliability of the detachable connection between the lumen support and the hook will not be reduced, nor will it affect the automati...

Embodiment 3

[0102] The structure of the endoluminal stent delivery system provided in this embodiment is basically the same as that of the endoluminal stent delivery system 100 provided in the first embodiment. In this example, see Figure 13a , the delivery system includes a tube body 40 , a handle housing 46 , a slider 47 and a hooking unit 50 . The tube body 40 includes an inner sheath 41 , an outer sheath 42 , an inner sheath core 43 and a tip 44 . The difference is that, in this embodiment, a limiting member 45 is provided on the outer surface of the inner sheath core tube 43 .

[0103] Specifically, please also see Figure 13a and Figure 13b , the limiting member 45 protrudes from the outer surface of the inner sheath core tube 43 in a direction away from the axial direction of the inner sheath core tube 43 . The limiting member 45 is fixed on the outer surface of the inner sheath core tube 43 near the distal end, and is closer to the distal end of the inner sheath core tube 43...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com