Preparation method and application of photocatalysis nanometer material for degrading TC (tetracycline)

A technology of nanomaterials and catalytic materials, applied in the field of one-step hydrothermal Ag+ doped SrTiO3 nanomaterials and its preparation, can solve the problems of interfering with the endocrine of aquatic species, discontinuity of wastewater discharge, refractory antibiotic degradation, etc., and achieve low cost , reduce energy consumption, and facilitate mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

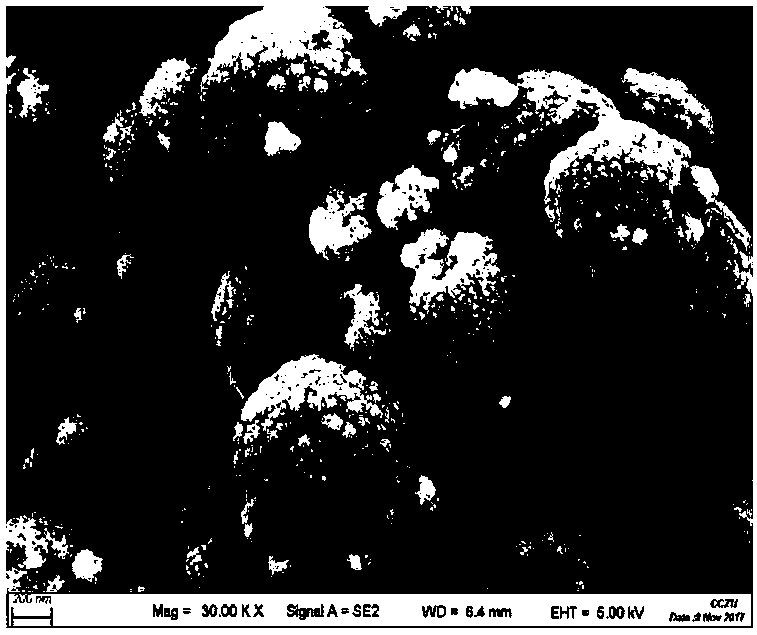

[0027] A kind of SrTiO prepared by hydrothermal method 3 Spherical nanomaterials are carried out as follows:

[0028] A. Dissolve 1.26g of citric acid in 15mL of absolute ethanol;

[0029] B, in step A solution, add dropwise the solution containing 1.058g Sr(NO 3 ) 2 15mL solution, then dropwise added 1.5mL isopropyl titanate, stirred to mix evenly to form a white solution;

[0030] C, drip NaOH solution in above-mentioned mixed solution, adjust pH;

[0031] D. Transfer the solution to a 100mL polytetrafluoroethylene liner, react at 150°C for 36 hours, and then wash three times with glacial acetic acid, absolute ethanol, and deionized water;

[0032] E. Dry the centrifuged product in an oven at 60-80°C for 12 hours.

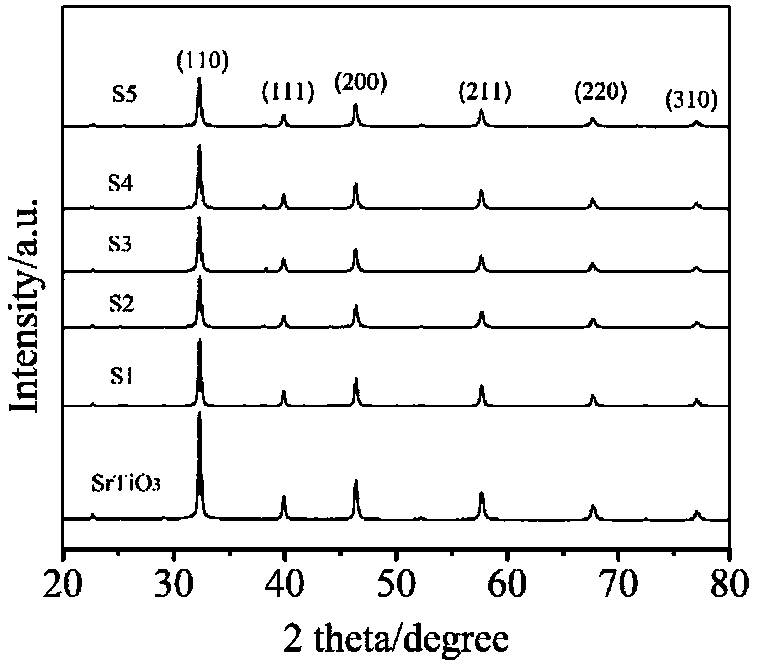

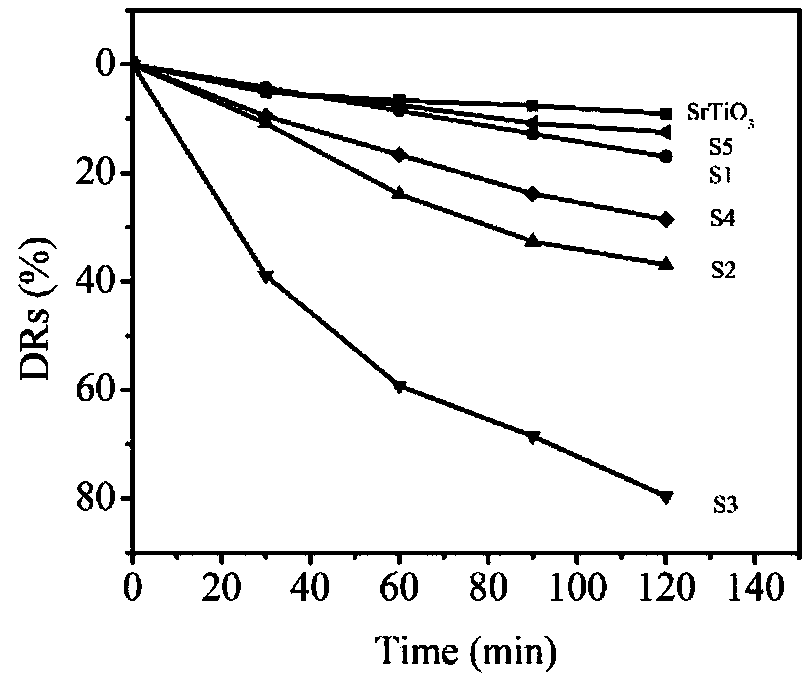

[0033] SrTiO prepared by the present invention 3 The degradation rate of nanomaterials to tetracycline is 9.09% when the xenon lamp is irradiated for 120 minutes.

Embodiment 2

[0035] A kind of Ag-SrTiO prepared by hydrothermal method 3 Spherical nanomaterials are carried out as follows:

[0036] A. Dissolve 1.26g of citric acid in 15mL of absolute ethanol;

[0037] B, in step A solution, add dropwise the solution containing 1.058g Sr(NO 3 ) 2 15mL solution, then dropwise added 1.5mL isopropyl titanate, stirred to mix evenly to form a white solution;

[0038] C, add dropwise to the white solution that contains 0.02497g AgNO 3 15mL solution;

[0039] D, drop NaOH solution in above-mentioned mixed solution, adjust pH;

[0040] E. Transfer the solution to a 100mL polytetrafluoroethylene liner, react at 150°C for 36 hours, and then wash three times with glacial acetic acid, absolute ethanol, and deionized water;

[0041] F. Dry the centrifuged product in an oven at 60-80°C for 12 hours.

[0042] Ag-SrTiO prepared by the present invention 3 Nanomaterials (S3), the degradation rate of tetracycline can reach 79.63% when illuminated by xenon light fo...

Embodiment 3

[0044] A. Dissolve 1.26g of citric acid in 15mL of absolute ethanol;

[0045] B, in step A solution, add dropwise the solution containing 1.058g Sr(NO 3 ) 2 15mL solution, then dropwise added 1.5mL isopropyl titanate, stirred to mix evenly to form a white solution;

[0046] C, add dropwise to the white solution that contains 0.0125g AgNO in step B 3 15mL solution;

[0047] D, drop NaOH solution in above-mentioned mixed solution, adjust pH;

[0048]E. Transfer the solution to a 100mL polytetrafluoroethylene liner, react at 150°C for 36 hours, and then wash three times with glacial acetic acid, absolute ethanol, and deionized water;

[0049] F. Dry the centrifuged product in an oven at 60-80°C for 12 hours.

[0050] Ag-SrTiO prepared by the present invention 3 Nanomaterials (S1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com