Chemical water treatment equipment

A technology for treatment equipment and chemical water, which is applied in water/sewage treatment, water treatment parameter control, sterilization/microdynamic water/sewage treatment, etc. It can solve the problem of unclean filter material backwashing of multi-media filter and affecting unit operation. efficiency, easy fouling and blocking of reverse osmosis membranes, etc., to achieve the effect of improving the level of water resource utilization and waste heat utilization, improving water production efficiency and water production, and prolonging emergency repair time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

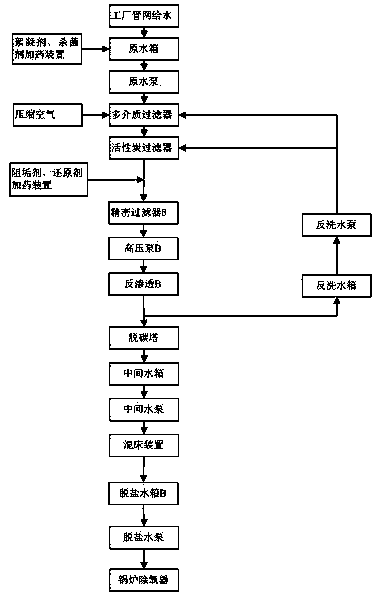

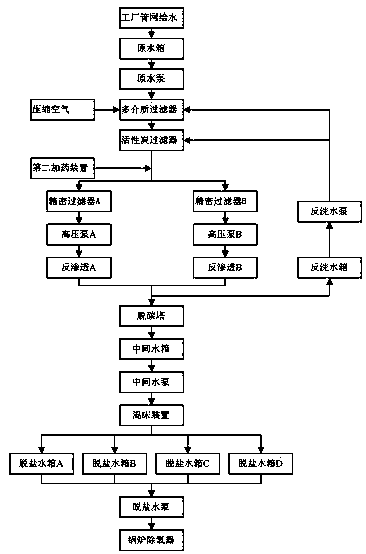

[0027] refer to figure 2 : A kind of chemical water treatment equipment of the present embodiment, comprises the raw water tank that connects successively, multimedia filter, activated carbon filter, 2 groups of reverse osmosis equipment groups that are connected in parallel, decarburization tower, intermediate water tank, intermediate water pump, mixed bed device and at least one desalinated water tank, the raw water tank communicates with the water supply system of the factory pipe network, the bottom of the multimedia filter is connected with a vent pipe for feeding compressed air into the multimedia filter, and the vent pipe is connected with a decompression device; the inlet pipe and the outlet pipe of the multimedia filter and the activated carbon filter are also connected with a bypass pipe with a control valve, and the outlet pipe of the activated carbon filter is also communicated with the second dosing device; the reverse osmosis After treatment by the equipment gro...

Embodiment 2

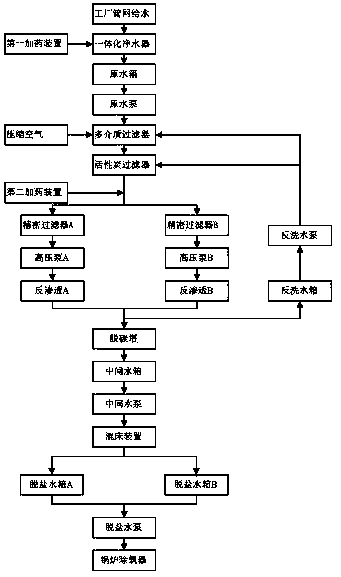

[0035] refer to image 3 : a kind of chemical water treatment equipment of the present embodiment,

[0036] An integrated water purifier is also provided between the raw water tank and the factory pipe network water supply system; the integrated water purifier is also communicated with the first dosing device.

[0037] The first dosing device is used for adding polyaluminum chloride (PAC) and / or bactericide and other chemical water purification agents to the integrated water purifier.

[0038] There are two desalination tanks.

[0039] The desalinated water tank is connected in parallel to the water outlet pipeline of the mixed bed device.

[0040] The use method and working principle of a kind of chemical water treatment equipment of the present invention are:

[0041] The impurities in the river water are flocculated by flocculants, sterilized by bactericides, and filtered by an integrated water purifier to remove large particles of impurities in the water source, then en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com