Bamboo-cellulose propellant powder

A technology of bamboo cellulose and propellant, applied in the field of pyrotechnic powder, can solve the problems of black smoke without guaranteed safety performance, affecting the effect of fireworks display, polluting the environment, etc., and achieving the effect of ensuring safety, low cost and low discharge pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: described bamboo cellulose propellant can be prepared according to the following method:

[0013] One, the preparation method of polymerization oxidant comprises the steps:

[0014] One, get potassium nitrate 78% by weight percentage, potassium ethoxide 12%, potassium dichromate 10% mix;

[0015] 2. Dissolve the mixture of the above step in water, add a catalytic amount of camphor, and heat to boiling; then filter, the sieve is the solid impurities that need to be removed, and the filtered solution is precipitated, cooled, dried, and air-dried, and the obtained powder is For the polymerization oxidant. In the above process, potassium nitrate, potassium ethoxide, and potassium dichromate are polymerized and clustered based on nitro radicals and potassium ions to form a polymer oxide with excellent performance, safety, stability and environmental protection.

[0016] Its two, according to percentage by weight: polymerization oxidant 40%, smokeless bamboo c...

Embodiment 2-5

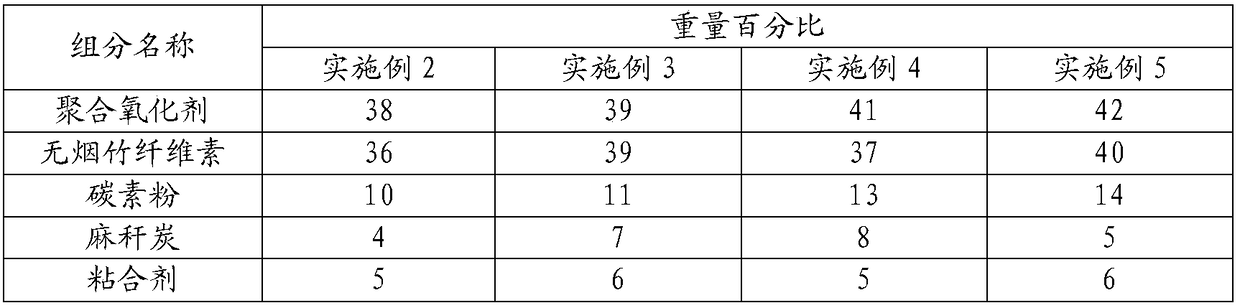

[0018] Embodiment 2-5 differs from embodiment 1 in that the proportioning of each component is different, see the following table:

[0019]

[0020] The propellant prepared by the above method was tested based on GB 10631-2013 and AQ4104-2008. The actual measurement results showed that the friction sensitivity was 22, the impact sensitivity was 38, the decomposition temperature was 75°C, and the moisture absorption rate was 1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com