Polar polypropylene graft and preparation method thereof

A polypropylene grafting and polar technology, which is applied in the field of polar polypropylene grafts and their preparation, can solve the problems of inability to meet the needs of operation and environmental protection, inability to completely avoid the use of styrene, difficulty in batching, etc. Degradation problem and the effect of low grafting rate, increasing polarity and low degree of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

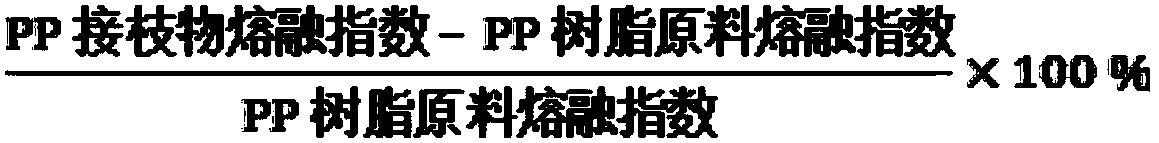

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a polar polypropylene graft, comprising:

[0033] Mixing step: uniformly mix the PP resin raw material with the formulated amount and the initiator monomer with the formulated amount to obtain the mixture;

[0034] Melting reaction step: the mixture is placed in the grafting equipment for melting reaction, the grafting equipment includes a mixing zone (pre-reaction zone), a grafting zone (main reaction zone) and a termination zone, wherein the mixing zone control temperature is 130 -200°C, the control temperature in the grafting area is 150-230°C, and the control temperature in the termination area is 150-220°C; add the formulated amount of initiator, polar monomer, and grafting aid in the mixing area, and add the formula in the termination area amount of antioxidant, extruded and granulated to obtain polar polypropylene grafts.

[0035] As a further embodiment, in the melting reaction step, the grafting equipment is a single-screw extruder, the...

Embodiment 1

[0039] A preparation method of a polar polypropylene graft, comprising:

[0040] Add 100 parts of homopolymerized PP resin raw material (melt index 11g / 10min (230°C, 2.16kg)) and 2.5 parts of butyl peroxymaleate into the mixer, stir at 1000r / min, and mix for 5 minutes. Put the uniformly mixed materials into a φ65 twin-screw extruder, the screw length-to-diameter ratio is 36:1, the temperature of the three reaction zones is 190°C, and the screw speed is 300rpm. In the end zone of the extruder, 0.3 parts of antioxidant 215 was added by metering, extruded and granulated to obtain the polar PP graft of the present invention.

Embodiment 2

[0042] A preparation method of a polar polypropylene graft, comprising:

[0043] Add 100 parts of homopolymer PP resin raw material (melt index 11g / 10min (230°C, 2.16kg)) and 5 parts of butyl peroxymaleate into the mixer, stir at 1000r / min, and mix for 5 minutes. Put the uniformly mixed materials into a φ65 twin-screw extruder, the screw length-to-diameter ratio is 36:1, the temperature of the three reaction zones is 190°C, and the screw speed is 300rpm. In the end zone of the extruder, 0.3 parts of antioxidant 215 was added by metering, extruded and granulated to obtain the polar PP graft of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com