High-hardness thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polymer material synthesis, can solve the problems of reducing the number of recyclable materials, limiting the application of high-hardness TPU, and poor processing performance, so as to avoid thermal oxidation degradation, outstanding economic benefits, Effect of low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

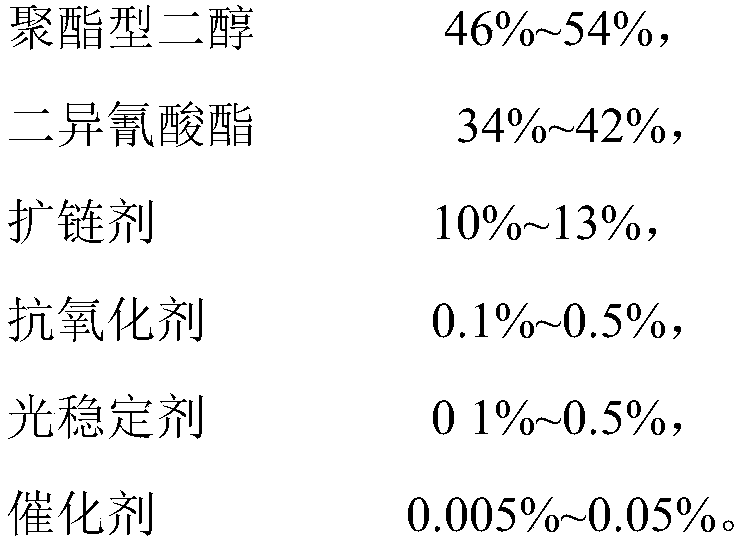

[0023] A high-hardness thermoplastic polyurethane elastomer made of the following raw materials in weight percentage:

[0024]

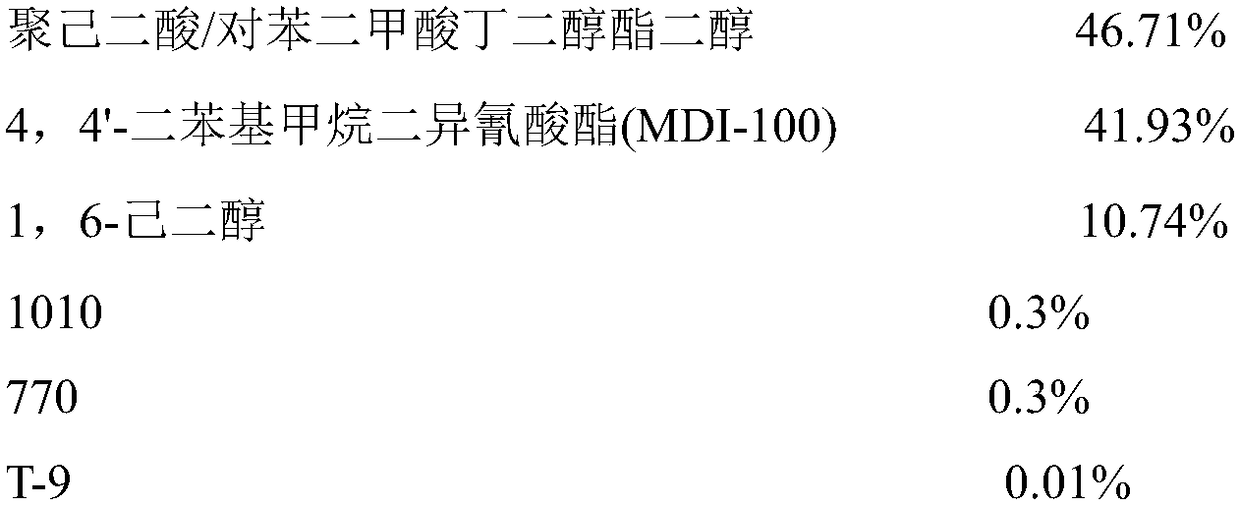

[0025] In the polyadipic acid / butylene terephthalate diol, terephthalic acid accounts for 1% of the total amount of dibasic acids, and the molecular weight of the polyester diol is 1000.

[0026] Preparation process: Mix and heat polyadipate / butylene terephthalate diol, 1010, 770 and T-9 to 100-115°C, mix well; heat MDI-100 to 45-55°C; 1 , 6-hexanediol is heated to 55-65°C; the heated raw material components are accurately metered and mixed and injected into the twin-screw reactor, and the mixed material is reacted and plasticized in the twin-screw reactor. product.

Embodiment 2

[0028] A high-hardness thermoplastic polyurethane elastomer made of the following raw materials in weight percentage:

[0029]

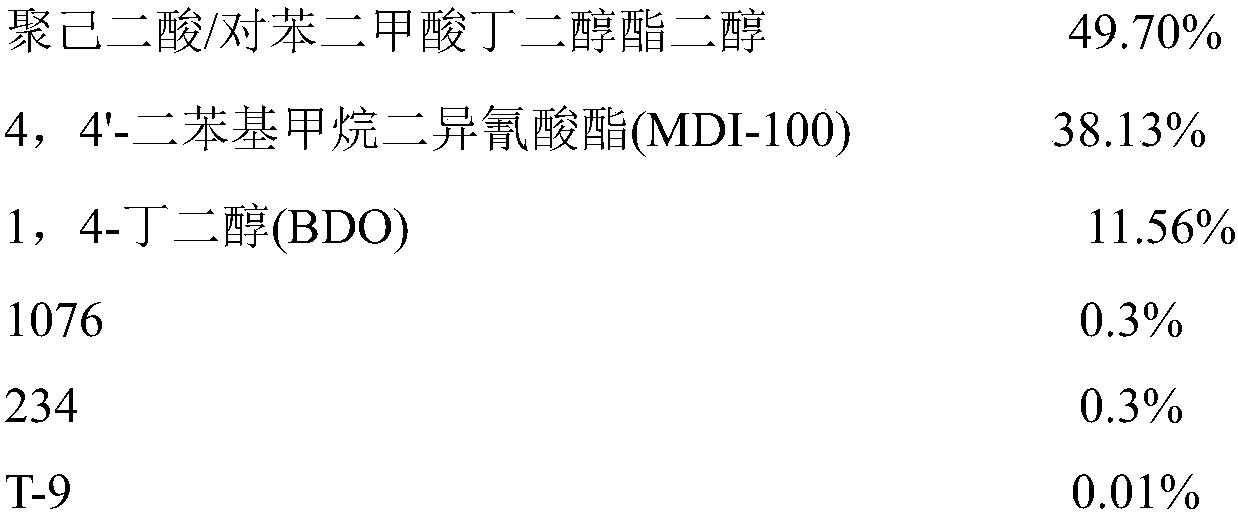

[0030] In the polyadipic acid / butylene terephthalate diol, terephthalic acid accounts for 5% of the total amount of dibasic acids, and the molecular weight of the polyester diol is 2000.

[0031] Preparation process: Mix and heat polyadipate / butylene terephthalate diol, 1076, 234 and T-9 to 100-115°C, mix well; heat MDI-100 to 45-55°C; BDO Heating to 45-55°C; the heated raw material components are accurately metered and mixed and injected into the twin-screw reactor, and the mixed material is reacted and plasticized in the twin-screw reactor, and related products are obtained after underwater pelletizing.

Embodiment 3

[0033] A high-hardness thermoplastic polyurethane elastomer made of the following raw materials in weight percentage:

[0034]

[0035]

[0036] In the polyadipic acid / butylene terephthalate diol, terephthalic acid accounts for 10% of the total amount of dibasic acids, and the molecular weight of the polyester diol is 2000.

[0037] Preparation process: Mix and heat polyadipate / butylene terephthalate diol, 1010, 770 and T-9 to 100-115°C, mix well; heat MDI-100 to 45-55°C; BDO Heating to 45-55°C; the heated raw material components are accurately metered and mixed and injected into the twin-screw reactor, and the mixed material is reacted and plasticized in the twin-screw reactor, and related products are obtained after underwater pelletizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com