Method for preparing multichannel narrow-band filtering pixel array

A pixel array and narrow-band filtering technology, which is applied in radiation pyrometry, spectrometry/spectrophotometry/monochromator, optics, etc., can solve problems such as low spectral sensitivity, inability to match pixels, and difficulty in guaranteeing performance. , to achieve the effect of simple process, flexible design and graphic realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

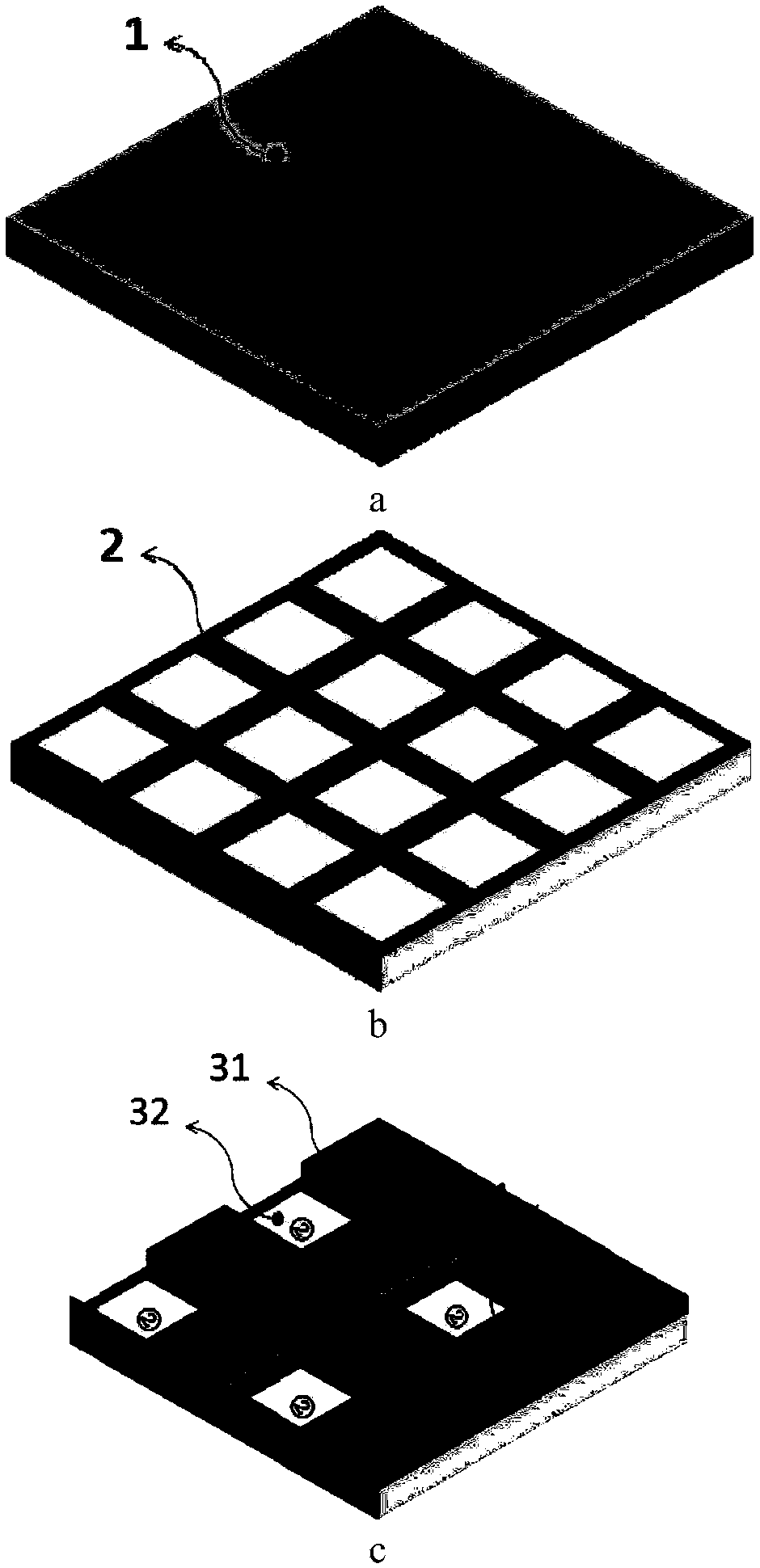

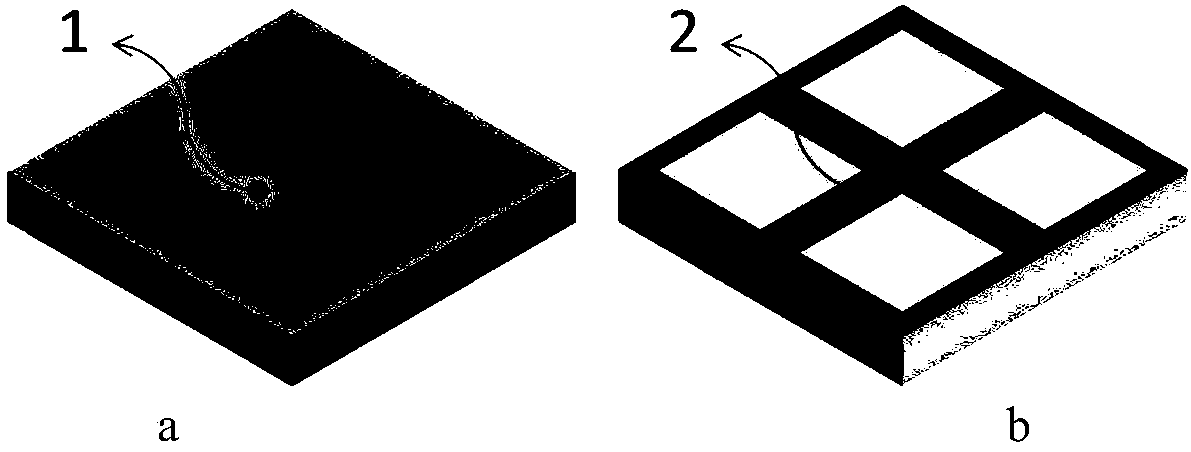

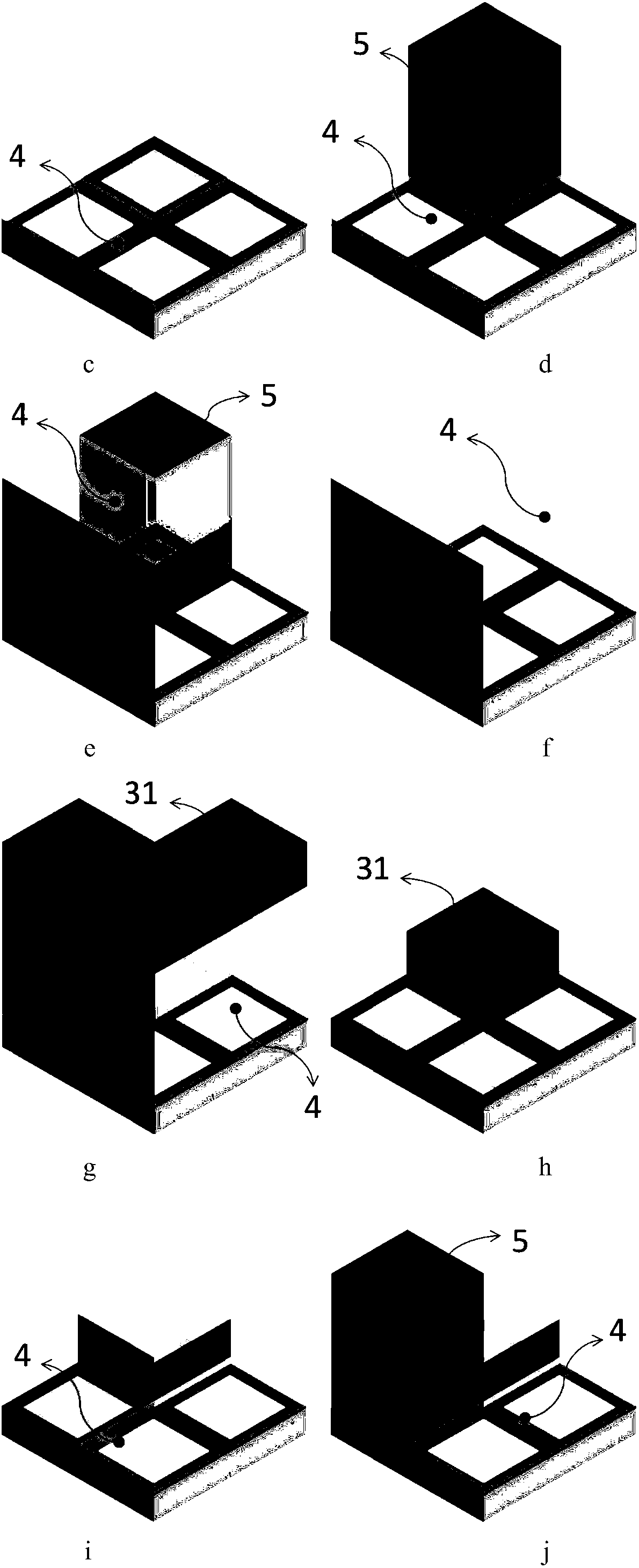

[0042] A method for preparing a multi-channel narrowband filter pixel array, comprising the steps of:

[0043] Step 1, using ultraviolet lithography and electron beam evaporation coating processes on the substrate to fabricate overlay marks and metal light-shielding grids between periodic filter pixel units;

[0044] Step 2, making a layer of metal aluminum conductive film on the surface of the substrate by ultraviolet lithography and electron beam evaporation coating as the starting substrate for electroplating;

[0045] Step 3, forming a photoresist mask by ultraviolet lithography;

[0046] Step 4, putting the substrate on which the photoresist pattern has been made into the electroplating solution pool for electroplating;

[0047] Step 5, removing the photoresist mask, and corroding the metal aluminum conductive film on the surface of the substrate to form an aluminum mask;

[0048] Step 6, using ion sputtering coating method to prepare F-P type periodic interference film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com