Ultrasonic gasoline cutting-welding machine

A cutting welding machine, ultrasonic technology, applied in the direction of welding equipment, gas flame welding equipment, combustion methods, etc., can solve the problems of fuel consumption, large power consumption, unsafe, etc., to reduce labor intensity, use safety, and gas supply A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

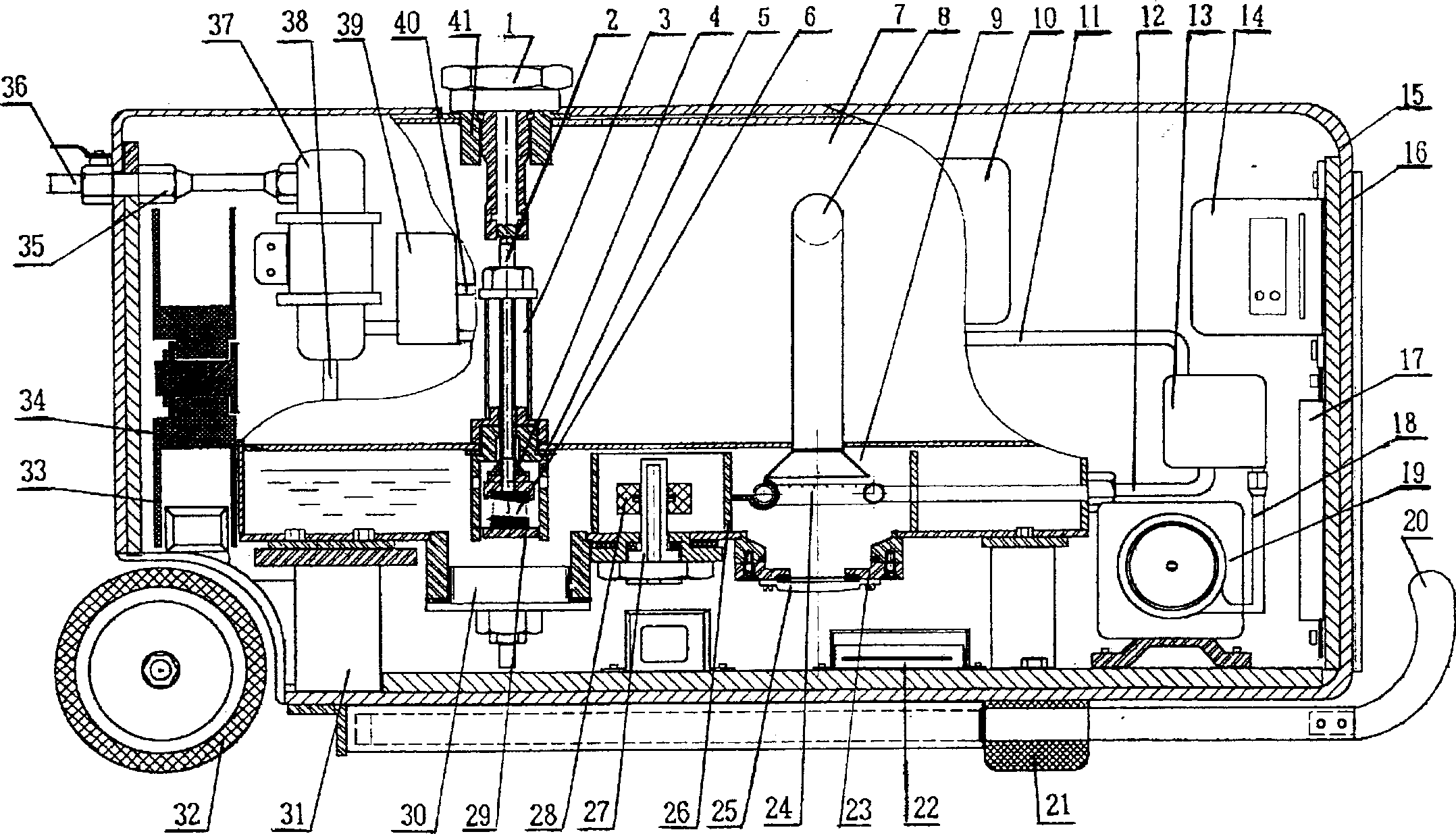

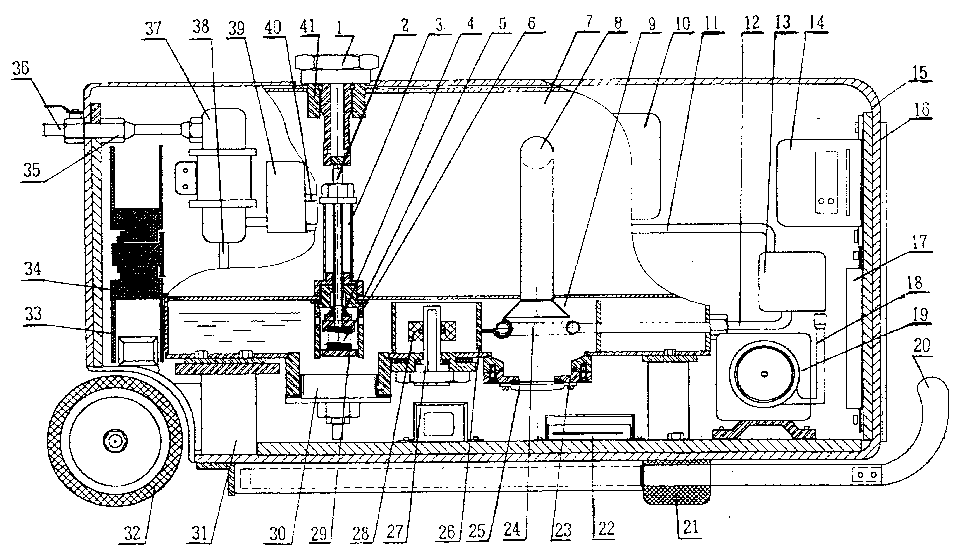

[0009] The wheel center with the take-up pulley 33 is fixed on the side wall of the fuel tank, and the fuel tank is divided into the main fuel tank 7 and the auxiliary fuel tank 9 of the upper and lower two parts by the transverse dividing plate 34. Two bosses are arranged on the lower end surface of the auxiliary fuel tank 9, and the mouth of the bosses is threaded to connect the bulky head 30 of the band sewage outlet and the base 23 with screws and sealing rings to fix the band transducer sheet 25.

[0010] The inner cavity of the auxiliary oil tank 9 is divided into four oil chambers by three longitudinal dividing plates 26 with evenly distributed gaps on the lower edge, and there is a gap between the dividing plate 26 and the transverse dividing plate 34 of the oil tank. An oil chamber in the middle is used to fix a pipe frame 27 with a magnetic pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com