Preparation method of methane steam reforming catalyst for fuel cell

A fuel cell and steam reforming technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of unstable catalyst structure, poor activity stability, and low activity rate, and achieve high thermal stability and toxicity resistance , stable structure and large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method for a catalyst for steam reforming of methane in a molten carbonate fuel cell, specifically comprising the following steps:

[0045] (1) Ball mill mixing: Add the three oxide powders of aluminum, zirconium and lanthanum into the ball mill according to the final composition ratio of the catalyst, and further crush and fully mix the three oxide powders by ball milling. The mixing time is 1 Hour.

[0046] (2) Powder molding: the powder prepared in step (1) is passed through a granulator to make uniform fine particle materials with a particle size of 10 mesh, and then the fine particle materials are added to a rotary tablet press or a hydroforming tablet press. , pressed into particles of prescribed shape.

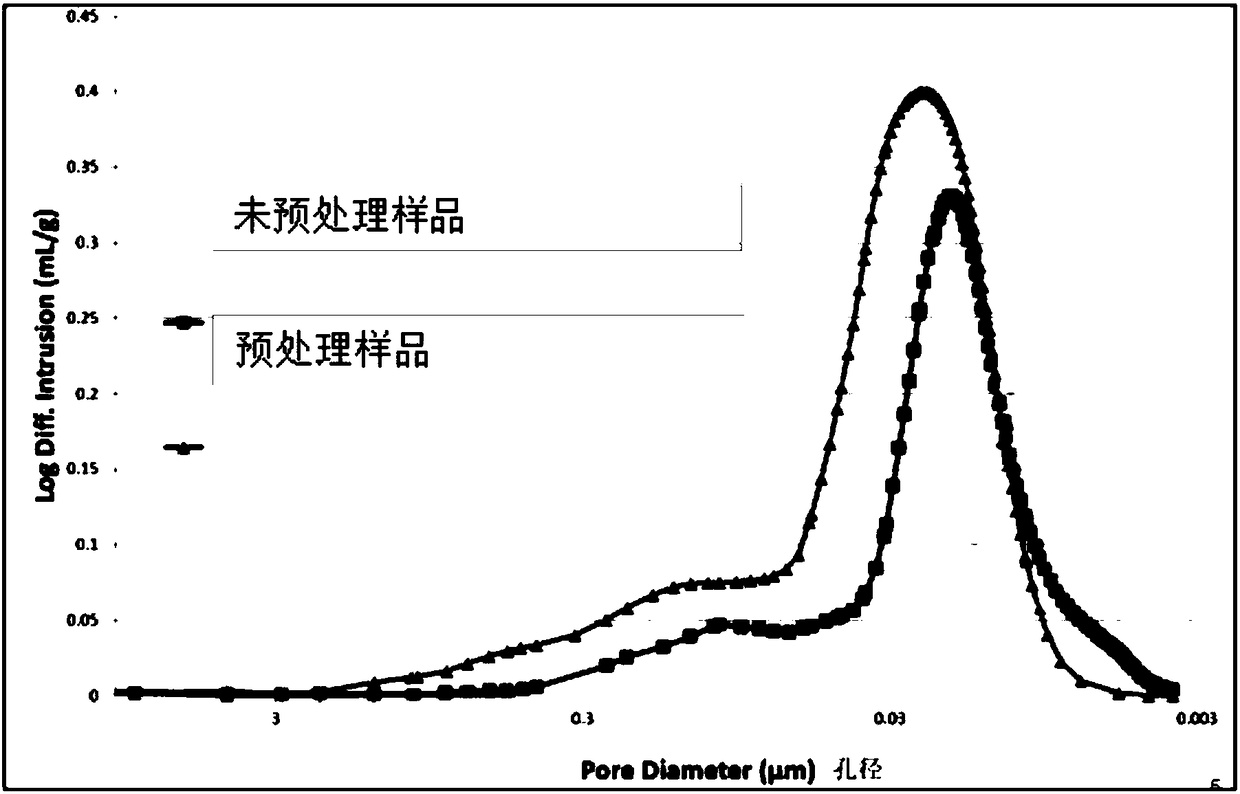

[0047] (3) Pretreatment: The particles with the specified shape prepared in step (2) are kept at a temperature of 50°C and a pressure of 0.01Mpa for 1 hour;

[0048] (4) Calcination of the carrier: Calcining the particles with the specified shape ...

Embodiment 2

[0052] A preparation method for a catalyst for steam reforming of methane in a molten carbonate fuel cell, specifically comprising the following steps:

[0053] (1) Ball mill mixing: Add the three oxides of aluminum, zirconium and lanthanum into the ball mill according to the final composition ratio of the catalyst, and further crush and fully mix the three oxides by ball milling. The mixing time is 12 hours.

[0054] (2) Powder molding: the powder prepared in step (1) is passed through a granulator to make uniform fine particle materials with a particle size of 500 mesh, and then the fine particle materials are added to a rotary tablet press or a hydroforming tablet press. , pressed into particles of prescribed shape.

[0055] (3) Pretreatment: The particles with the specified shape prepared in step (2) are subjected to a temperature of 700°C and a pressure of 2.0Mpa for a residence time of 24h;

[0056] (4) Calcination of the carrier: Calcining the particles with the specif...

Embodiment 3

[0059] A preparation method for a catalyst for steam reforming of methane in a molten carbonate fuel cell, specifically comprising the following steps:

[0060] (1) Ball mill mixing: Add the three oxides of aluminum, zirconium and lanthanum into the ball mill according to the final composition ratio of the catalyst. The three oxides are further crushed and fully mixed by ball milling. The mixing time is 6 hours.

[0061] (2) Powder molding: the powder prepared in step 1 is passed through a granulator to make uniform fine particle materials with a particle size of 60 mesh, and then the fine particle materials are added to a rotary tablet press or a hydroforming tablet press. Granules compressed into prescribed shapes.

[0062] (3) Pretreatment: The particles of the specified shape prepared in step (2) are subjected to a temperature of 100°C, a pressure of 0.1Mpa, and a residence time of 5h;

[0063] (4) Calcination of the carrier: the pre-treated particles of the specified sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com