A kind of hydrogen peroxide concentration device

A concentration device, hydrogen peroxide technology, applied in the direction of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve liquid-phase catalytic decomposition , gas phase explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

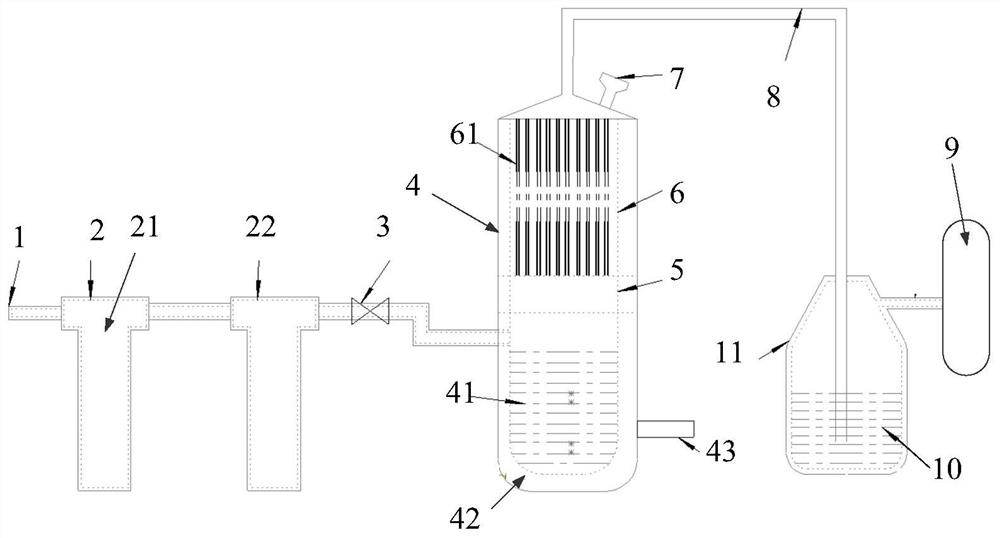

[0030] Such as figure 1 As shown, the hydrogen peroxide concentration device in the embodiment of the present invention includes a filter device 2 communicated with the raw material inlet 1, and an evaporator 4 connected to the filter device 2 in a cut-off manner, respectively connected to the evaporator 4 and the decompression device. The condensation pipe 8 connected to the device 9 and the concentrated hydrogen peroxide chamber 10. An aluminum-based capillary channel component 6 is provided in the evaporator 4 close to the entrance of the condensation pipe 8 .

[0031] Impurities such as organic matter and metal ions in the hydrogen peroxide produced by industrial devices can be removed through the filter device installed, thereby inhibiting liquid-phase cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com