A method of microwave calcining zinc hydrometallurgy to purify cobalt-nickel slag to produce cobalt concentrate

A hydrometallurgy, cobalt-nickel slag technology, applied in the field of hydrometallurgy applications, can solve the problems of only considering the recycling of metal zinc, little research and extraction of cobalt, no effective extraction methods, etc., to solve safety and environmental protection problems, high efficiency. Technical level and economic value, the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

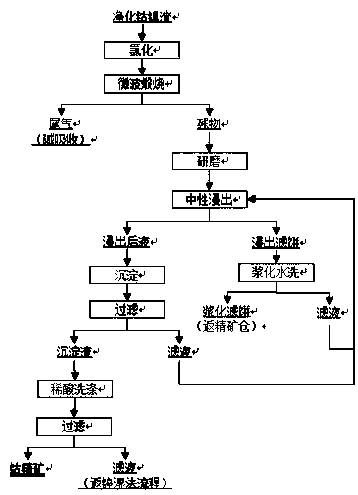

Method used

Image

Examples

Embodiment 1

[0021] Take 100g of purified cobalt-nickel slag (0.3% cobalt content, 40% zinc content, 15% water content), and take industrial grade NH 4 Dissolve 5g of Cl in 200ml of water, mix cobalt nickel slag with NH 4 Cl was fully mixed and chlorinated at a dry weight ratio of 20:1 for 45 minutes; the cobalt-nickel slag was calcined in an industrial microwave oven at a temperature of 500°C for 45 minutes. The calcined cobalt-nickel slag is naturally cooled to normal temperature, and then ground, and the ground material is 60g, and the particle size is more than 200 mesh, which is more than 87%; at normal temperature, the ground material is neutrally leached for 3 hours according to the liquid-solid ratio of 10:1, and filtered; Add precipitant Na to the filtered solution according to 2 times the cobalt content 2 S was used for replacement precipitation, the precipitation temperature was controlled at 50°C, and the precipitation stirring time was 0.5h; after the precipitation was suffic...

Embodiment 2

[0023] Take 100g of purified cobalt-nickel slag (1.0% cobalt content, 38% zinc content, 14% water content), take industrial grade NH 4 Dissolve 2.5g of Cl in 200ml of water. Cobalt nickel slag NH 4 Cl was fully mixed and chlorinated at a dry weight ratio of 40:1 for 60 minutes; the cobalt-nickel slag was calcined in an industrial microwave oven at a temperature of 900°C for 20 minutes. The calcined cobalt-nickel slag is naturally cooled to normal temperature, and then ground. The ground material is 55g, and the particle size is over 200 mesh, and the percentage is more than 90%. The ground material is neutrally leached for 4 hours at a liquid-solid ratio of 15:1 at room temperature. Add precipitant Na to the filtered solution according to 1.3 times the cobalt content 2 S was used for replacement precipitation, the precipitation temperature was controlled at 60°C, and the precipitation stirring time was 1h; after the precipitation was sufficient, the solution was filtered and...

Embodiment 3

[0025] Take 100g of purified cobalt-nickel slag (0.5% cobalt content, 35% zinc content, 15.5% water content), and take industrial grade NH 4 Cl 4g was dissolved in 200ml of water. The cobalt-nickel slag was fully mixed and chlorinated with NH4Cl at a dry weight ratio of 25:1 for 50 minutes; the cobalt-nickel slag was calcined in an industrial microwave oven at a temperature of 700°C for 30 minutes. The calcined cobalt-nickel slag was naturally cooled to normal temperature, and then ground. The ground material was 57g, and the particle size was more than 88% over 200 mesh. The ground material was neutrally leached for 3.5 hours at a liquid-solid ratio of 12:1 at room temperature. Add precipitant Na to the filtered solution according to 1.4 times the cobalt content 2 S was used for replacement precipitation, the precipitation temperature was controlled at 55°C, and the precipitation stirring time was 45 minutes; after the precipitation was sufficient, the solution was filtered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com