A method for preparing carbon fiber insulation felt from short fibers

A short fiber and carbon fiber technology, applied in the field of carbon fiber thermal insulation material preparation, can solve the problems of uneven density of carbon fiber composite materials, high resin content, easy surface cracking, etc., to solve safety and environmental protection problems, improve the overall utilization rate, and increase enterprise benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

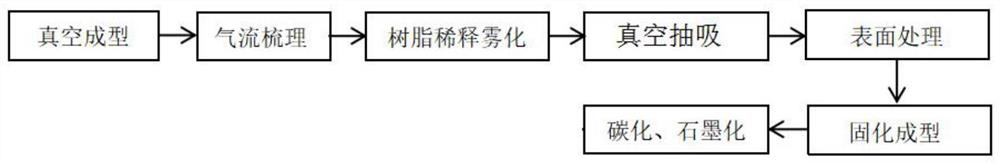

[0038] A method for preparing carbon fiber insulation felt from short fibers, comprising the following steps:

[0039] 1. Vacuum forming: put 10kg of short fibers with a length of 3mm into the mold, and form them under the condition of a vacuum of 3000pa to obtain a prefabricated embryo body;

[0040] 2. Airflow carding: open the airflow carding device to adjust the airflow carding angle to 15° and the airflow velocity to 0.8m / s; comb the surface of the prefabricated embryo body to obtain a prefabricated embryo body with a smooth surface;

[0041] 3. Resin dilution and atomization: dilute to obtain diluted resin, and spray the atomized resin on the top of the prefabricated embryo body;

[0042] 4. Vacuum suction: atomized resin infiltrates the prefabricated embryo body under the action of vacuum;

[0043] 5. Surface treatment: After the upper and lower surfaces of the prefabricated embryo body are treated, a high-temperature cloth is pasted, and the molding is put into an ove...

Embodiment 2

[0049] A method for preparing carbon fiber insulation felt from short fibers, comprising the following steps:

[0050] 1. Vacuum forming: put 11kg of short fibers with a length of 4mm into the mold, and form them under the condition of a vacuum of 2000pa to obtain a prefabricated embryo body;

[0051] 2. Airflow carding: open the airflow carding device to adjust the airflow carding angle to 20° and the airflow velocity to 0.8m / s; comb the surface of the prefabricated embryo body to obtain a prefabricated embryo body with a smooth surface;

[0052] 3. Resin dilution and atomization: dilute to obtain diluted resin, and spray the atomized resin on the top of the prefabricated embryo body;

[0053] 4. Vacuum suction: atomized resin infiltrates the prefabricated embryo body under the action of vacuum;

[0054] 5. Surface treatment: After the upper and lower surfaces of the prefabricated embryo body are treated, a high-temperature cloth is pasted, and the molding is put into an ove...

Embodiment 3

[0060] A method for preparing carbon fiber insulation felt from short fibers, comprising the following steps:

[0061] 1. Vacuum forming: put 13kg of short fibers with a length of 5mm into the mold, and form them under the condition of a vacuum of 5000pa to obtain a prefabricated embryo body;

[0062] 2. Airflow carding: open the airflow carding device to adjust the airflow carding angle to 30° and the airflow velocity to 1.1m / s; comb the surface of the prefabricated embryo body to obtain a prefabricated embryo body with a smooth surface;

[0063] 3. Resin dilution and atomization: dilute to obtain diluted resin, and spray the atomized resin on the top of the prefabricated embryo body;

[0064] 4. Vacuum suction: atomized resin infiltrates the prefabricated embryo body under the action of vacuum;

[0065] 5. Surface treatment: After the upper and lower surfaces of the prefabricated embryo body are treated, a high-temperature cloth is pasted, and the molding is put into an ove...

PUM

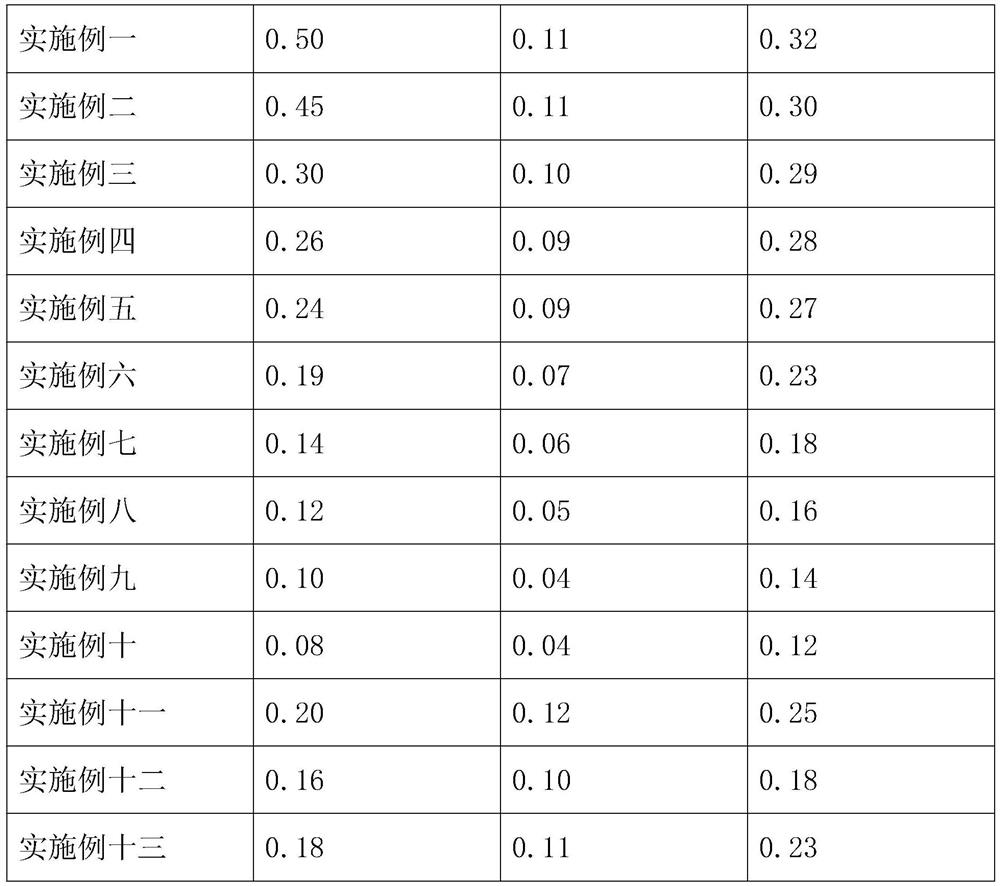

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com