Sealed feeding device for pyrolysis carbon gas combined production and feeding method of sealed feeding device

A technology of feeding device and feeding method, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problem of hindering the popularization and application of biomass pyrolysis and coal gasification technology, reducing the safety of gas storage, feeding machine Problems such as poor sealing can achieve the effect of achieving continuity and uniformity, overcoming material arching, and ensuring continuity and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

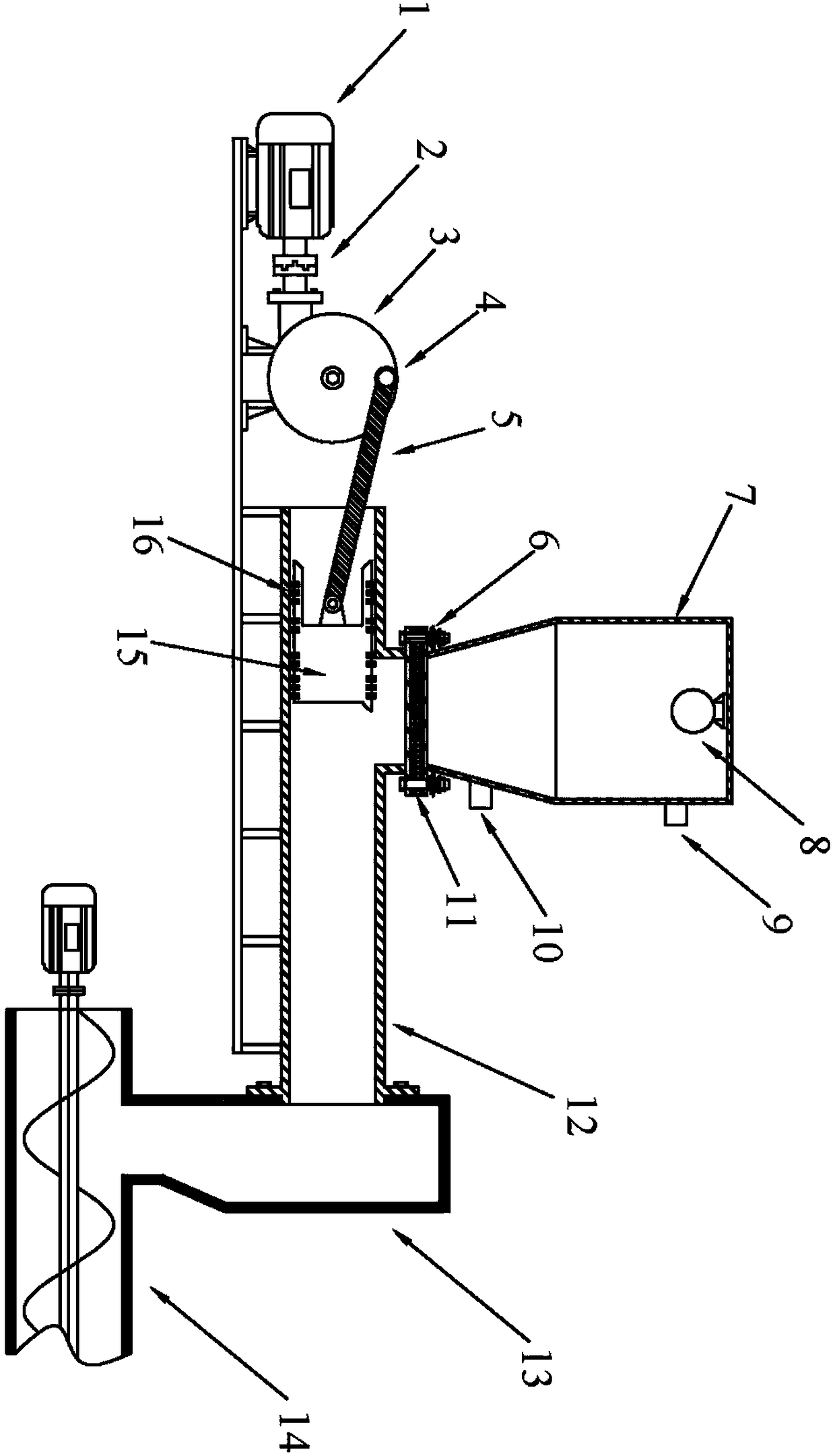

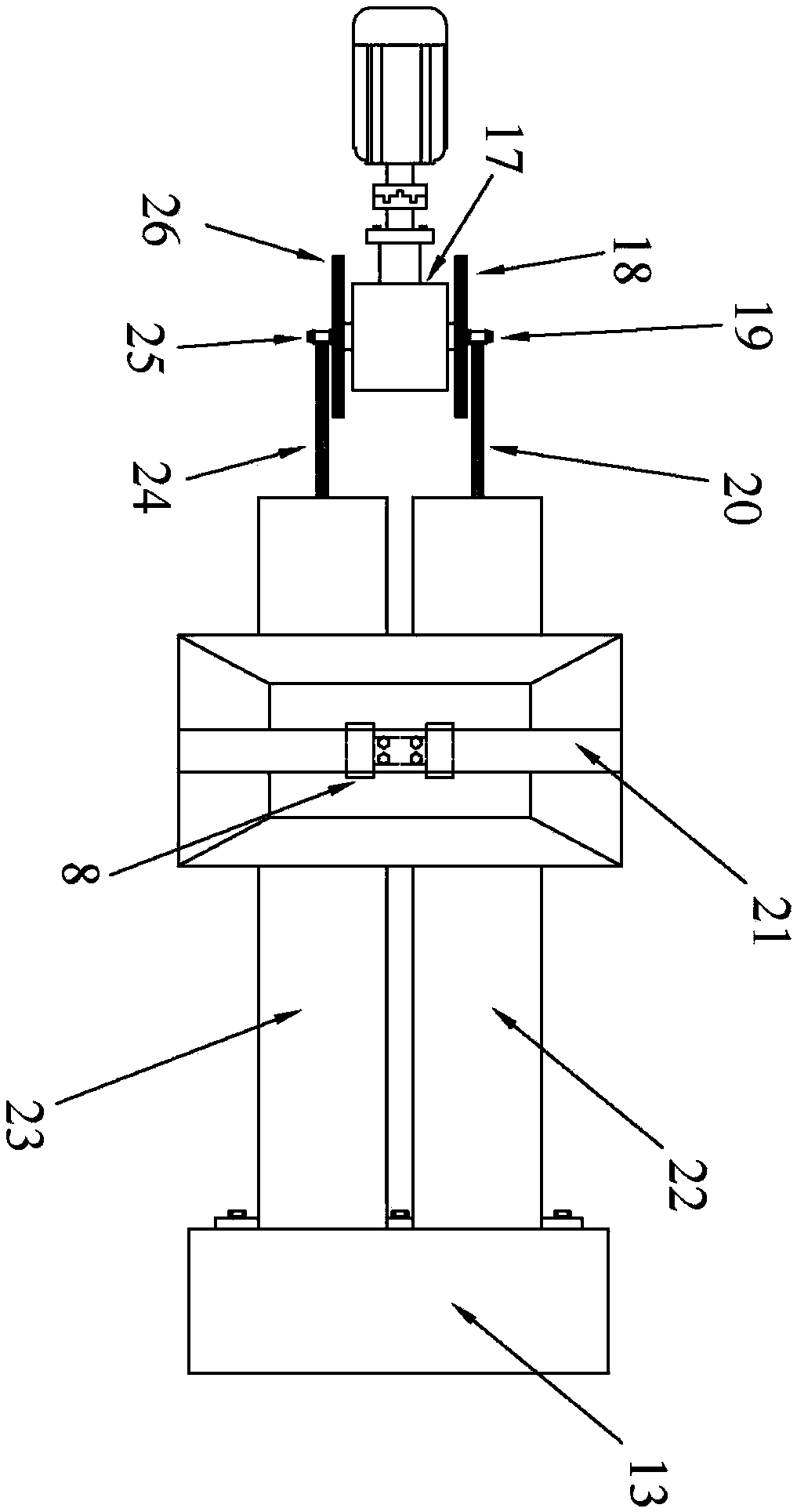

[0022] For the convenience of description, the sealed feeding process and device will be described in detail below in conjunction with the accompanying drawings.

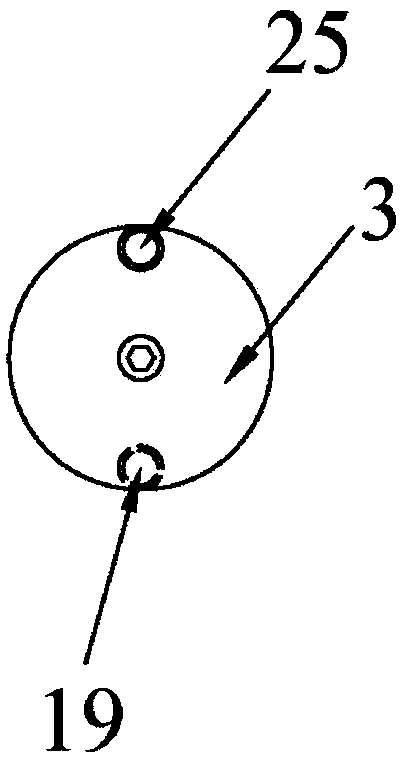

[0023] Such as Figure 1 to Figure 5 As shown in , a sealed feeding device, the feeding cylinder 12 is a national standard stainless steel pipe, connected to the collector 13 at its discharge end, fixed by bolts, and the lower part of the collector 13 is connected to the biomass pyrolysis furnace 14 . A push piston 15 is installed inside the delivery tube, and a wear-resistant rubber ring 16 is provided on the piston. A hopper 7 is installed at the feeding port of the feeding barrel, and a shock-absorbing rubber pad 11 is lined at the connection between the two. At the same time, a shock-absorbing spring 6 is installed at the bolt, and a high-frequency vibrator 8 is installed on the hopper beam 21. An upper material level gauge 9 and a lower material level gauge 10 are respectively installed at the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com