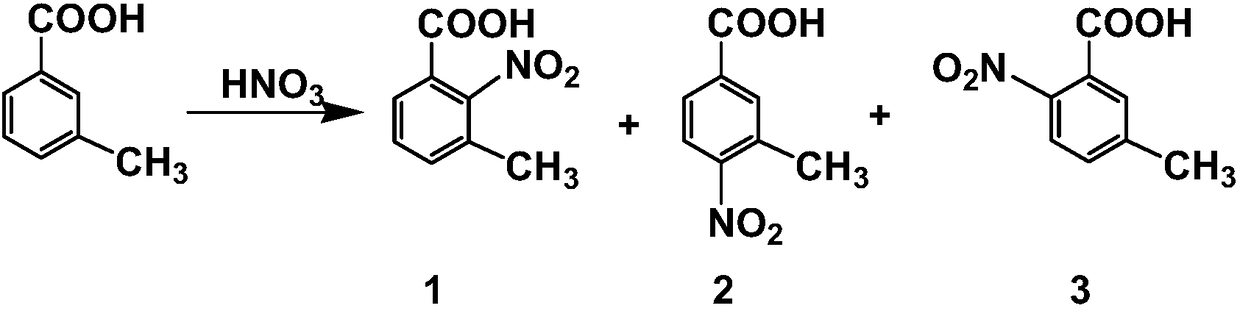

Comprehensive utilization method of m-toluic acid nitration solid waste

A technology of m-toluic acid and toluic acid, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of low product selectivity and many nitrification by-products, etc., and achieve obvious economic value. , The effect of remarkable economic benefit and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

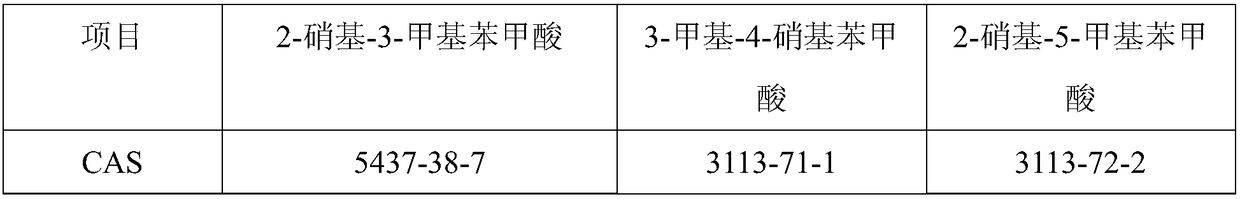

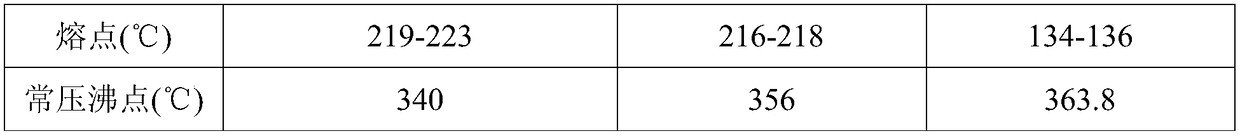

[0039] The composition of solid waste from the nitration reaction of m-methylbenzoic acid is: the mass percentage of 2-nitro-3-methylbenzoic acid is 10%, the mass percentage of 3-methyl-4-nitrobenzoic acid is 28%, The mass percentage of 2-nitro-5-methylbenzoic acid is 62%. In step (1), the solid waste of the nitrification reaction is dissolved and cleared with a NaOH aqueous solution with a concentration of 30% by mass, and the final pH is 12.8. Step (2) Use 25% concentrated hydrochloric acid to adjust the pH of the solution to 4.4 to obtain 51.8 g of 3-methyl-4-nitrobenzoic acid with a recovery rate of 92.6%. In step (3), 25% concentrated hydrochloric acid was used to adjust the pH of the solution to 3.2 to obtain 18.3 g of 2-nitro-3-methylbenzoic acid with a recovery rate of 91.5%. In step (4), 25% concentrated hydrochloric acid was used to adjust the pH of the solution to 1.2 to obtain 96.3 g of 2-nitro-5-methylbenzoic acid with a recovery rate of 77.7%. , The total recove...

Embodiment 2

[0041] The composition of the solid waste from the nitration reaction of m-methylbenzoic acid is: the mass percentage of 2-nitro-3-methylbenzoic acid is 15%, the mass percentage of 3-methyl-4-nitrobenzoic acid is 20%, The mass percentage of 2-nitro-5-methylbenzoic acid is 65%. Step (1) Use a KOH aqueous solution with a concentration of 20% by mass to dissolve the solid waste of the nitrification reaction, and the final PH=8.4. Step (2) Use 10% dilute nitric acid to adjust the pH of the solution to 4.0 to obtain 36.8 g of 3-methyl-4-nitrobenzoic acid with a recovery rate of 92.0%. Step (3) Use 10% dilute nitric acid to adjust the pH of the solution to 2.5 to obtain 28.5 g of 2-nitro-3-methylbenzoic acid with a recovery rate of 95.0%. Step (4) Use 10% dilute nitric acid to adjust the pH of the solution to 0.5 to obtain 94.9 g of 2-nitro-5-methylbenzoic acid with a recovery rate of 73.0%. , The total recovery rate of the three is 80.1%.

Embodiment 3

[0043] The composition of solid waste from the nitration reaction of m-methylbenzoic acid is: 2-nitro-3-methylbenzoic acid with a mass percentage of 20%, 3-methyl-4-nitrobenzoic acid with a mass percentage of 10%, The mass percentage of 2-nitro-5-methylbenzoic acid is 70%. Step (1) Use 15% NaHCO by mass percentage 3 The aqueous solution will dissolve the solid waste of the nitration reaction, and the final PH=7.5. Step (2) Use 50% phosphoric acid to adjust the pH of the solution to 5.5 to obtain 19.1 g of 3-methyl-4-nitrobenzoic acid with a recovery rate of 95.4%. Step (3) Use 50% phosphoric acid to adjust the pH of the solution to 4.0 to obtain 36.2 g of 2-nitro-3-methylbenzoic acid with a recovery rate of 90.5%. Step (4) Use 50% phosphoric acid to adjust the pH of the solution to 2.4 to obtain 116.2 g of 2-nitro-5-methylbenzoic acid with a recovery rate of 83.0%. , The total recovery rate of the three is 85.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com