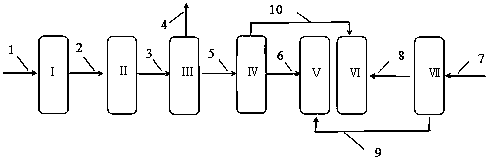

Novel method for producing ammonium persulfate through ammonium sulfate electrolysis

A technology of ammonium persulfate and ammonium sulfate, which is applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of high environmental protection pressure, low product purity, and complicated purification of production enterprises, and achieve waste liquid treatment and production process optimization. , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] [Example 1] The ammonium sulfate produced by the ammonium sulfate section of the coking enterprise is used as the anolyte, the sulfuric acid solution is used as the catholyte, the anode solution enters the electrolytic cell with 120~140t / h for electrolysis at a flow rate of 15~35t / h; The electrolyzed anolyte contains 200g / L ammonium persulfate, with an acidity of 0.4~0.5mol / L, and is pumped to the ammonium sulfate feeding reactor; the ammonium sulfate produced by the coking enterprise is added to the reactor by screw conveying to The concentration is 1.25~1.26g / mL, and liquid ammonia is passed through to adjust the pH of the solution to about 6~7; the solution is filtered through the anode material filter to remove Fe(OH)3, and sulfuric acid with an acidity of 3.0~4.0 is used for backwashing every two days One time; the filtered solution enters the cooling tank and cools the solution to -3~-8°C to crystallize ammonium persulfate; the feed liquid containing crystals is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com