Method for detecting content of nickel, cobalt and manganese in ternary material or ternary precursor

A technology of ternary materials and precursors, applied in the direction of electrochemical variables of materials, analysis of materials by chemical reactions, and material analysis by observing the influence of chemical indicators, etc., can solve the problems of identification difficulties, increased filtrate, nickel Difficulty in shaking the Erlenmeyer flask, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0101] According to a preferred embodiment of the present invention, the molar amount of nickel in the ternary material or ternary precursor can be obtained by using n(Ni / Co / Mn) and n(Mn / Co) for differential calculation.

[0102] In a further preferred embodiment, the molar amount of nickel in the ternary material or the ternary precursor is obtained as follows:

[0103] n(Ni)=n(Ni / Co / Mn)-n(Mn / Co) Formula (4).

[0104] Wherein, n (Ni) is the molar weight of nickel in the ternary material or ternary precursor that the quality that takes in step 1 ' is m.

[0105] In a further preferred embodiment, the mass percentage of nickel in the ternary material or the ternary precursor is obtained as follows:

[0106]

[0107] Among them, in formula (4-1), M Ni Represents the molar mass of nickel, and m represents the mass of the ternary material or ternary precursor in step 1'.

[0108] Step 5. Subtract the molar amount of manganese obtained in step 2 from the total molar amount of...

Embodiment 1

[0132] (1) Sample preparation

[0133] Accurately weigh 2.5g Ni 0.5 co 0.2 mn 0.3 (OH) 2 , add 60mL (1+1 hydrochloric acid), heat to dissolve, dilute to 1000mL volumetric flask, shake well for later use.

[0134] (2) Sample testing

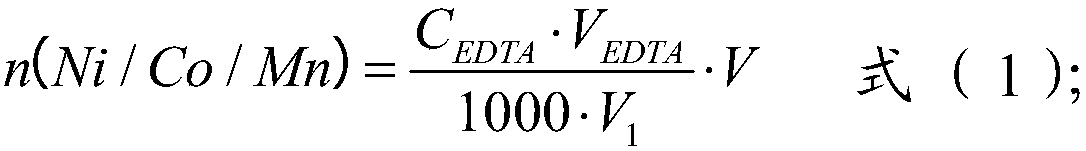

[0135] (2.1) Accurately pipette 25mL of the dissolved and constant volume solution, add 10mL of ammonia-ammonium chloride buffer solution, 0.03g of ammonium viuridine as indicator, titrate to the end point with EDTA standard solution, the color changes from bright yellow to purple, Record the volume of EDTA consumed. According to the formula (1), the total molar amount n(Ni / Co / Mn) of nickel, cobalt and manganese is obtained.

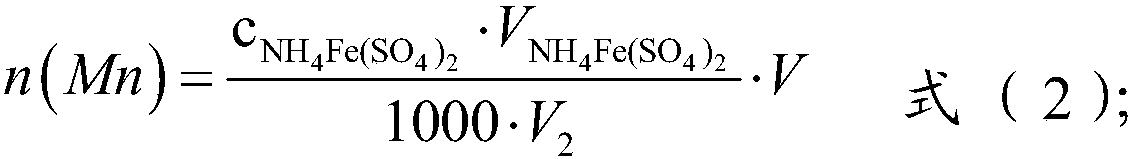

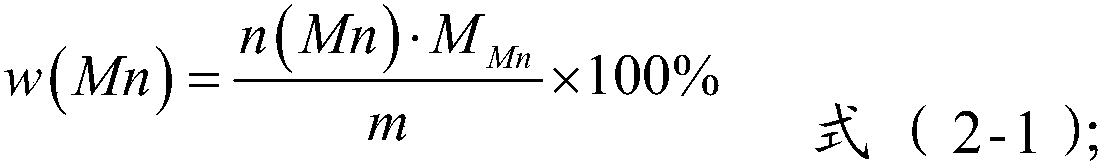

[0136] (2.2) Accurately pipette 25mL of the dissolved sample solution, add 6mL of concentrated phosphoric acid, heat on an electric stove at 230°C until the liquid level is calm and a large amount of white smoke is emitted, take it off, cool for 10s, add 1g of ammonium nitrate, and use Wash the ear ball and blow away ...

Embodiment 2

[0142] Repeat the process of Example 1, the difference is: in (2.2), add 4mL concentrated phosphoric acid, the content of manganese obtained is 17.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com