Single-side chip discharging machine

A kind of unloading, unilateral technology, applied in the field of unilateral unloading machine, it can solve the problems of battery leakage, reducing the pass rate of silicon wafers, and not setting up the sampling inspection of weighing units, so as to improve the quality and pass rate, and improve work efficiency. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

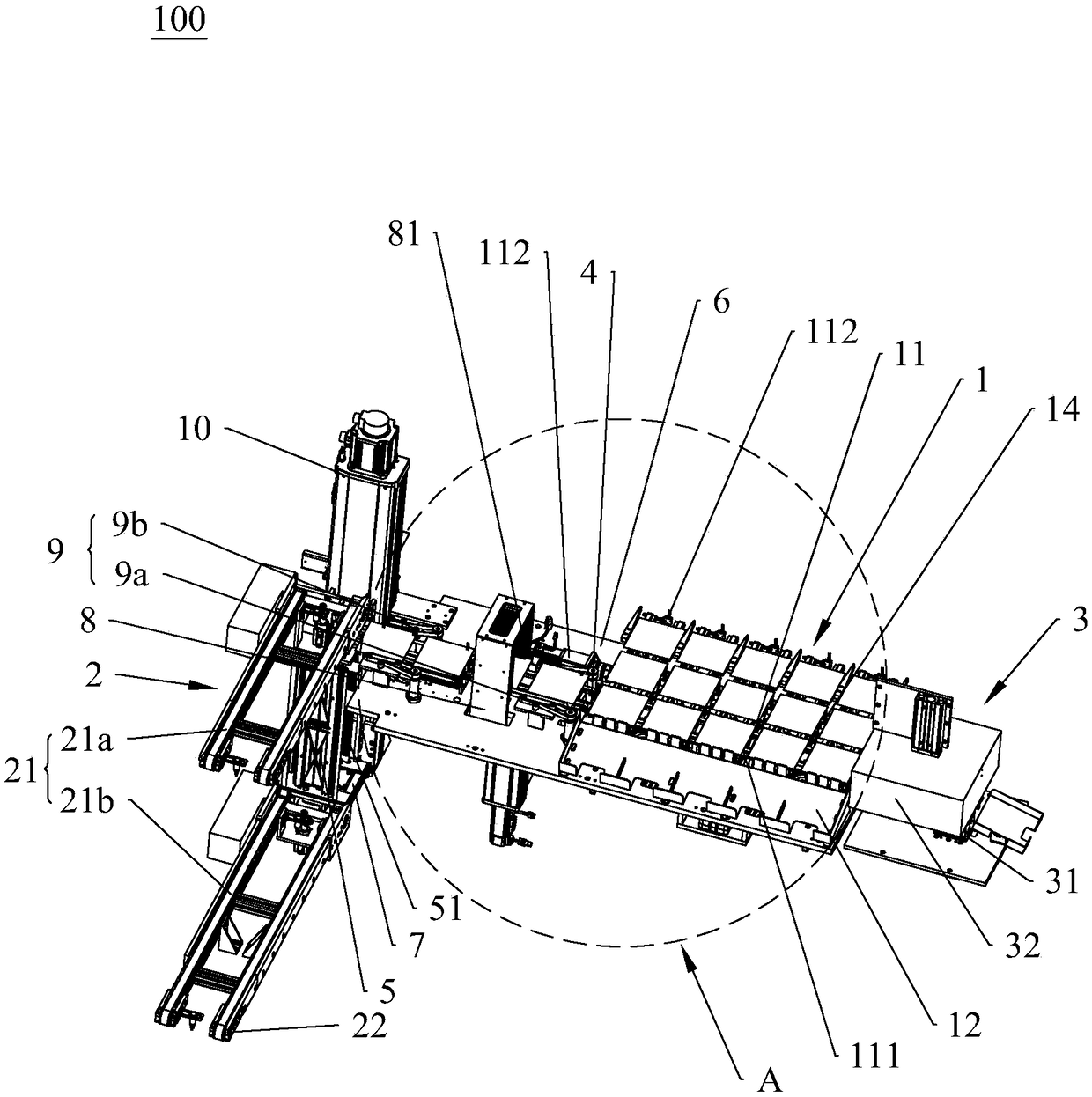

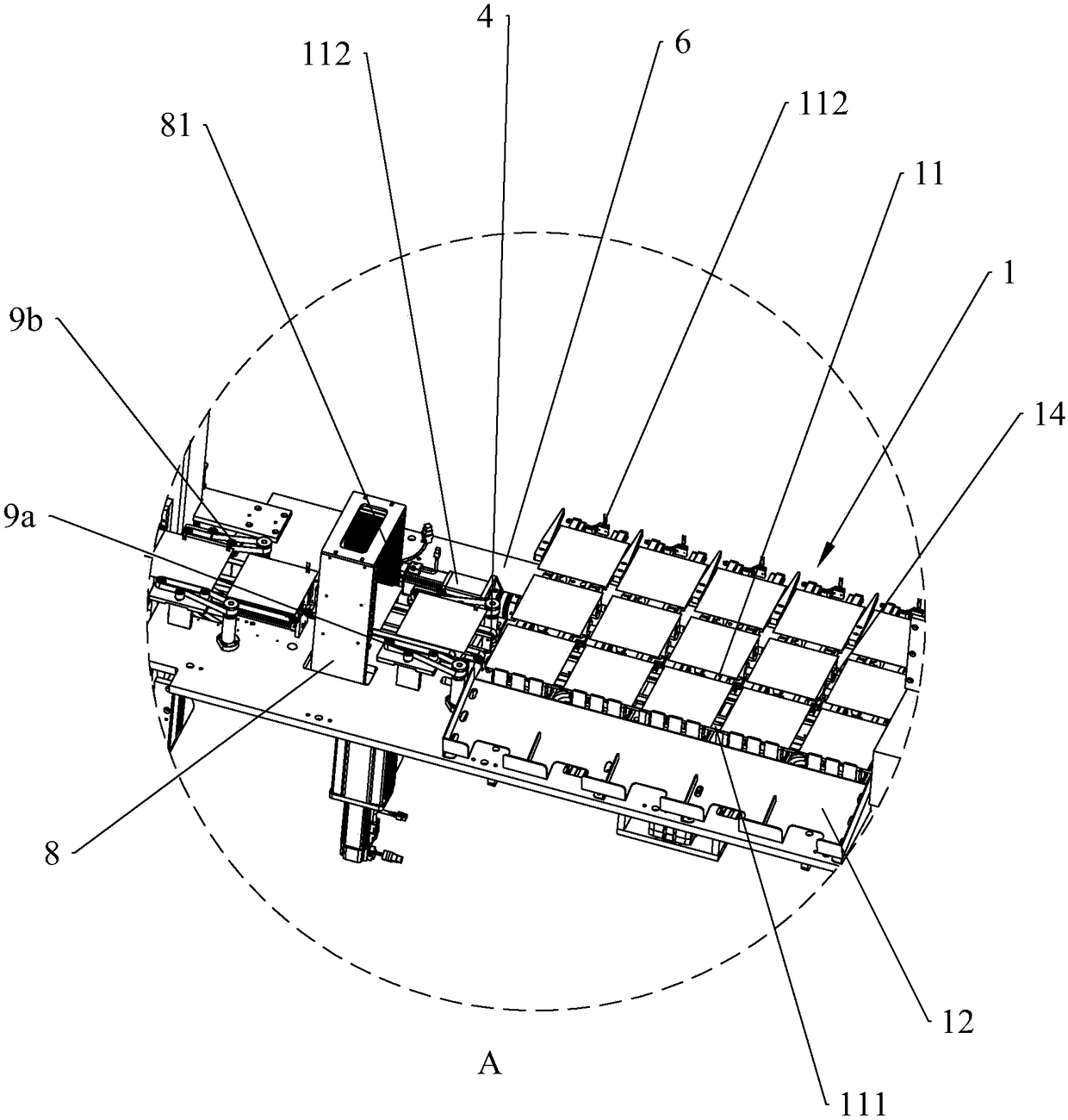

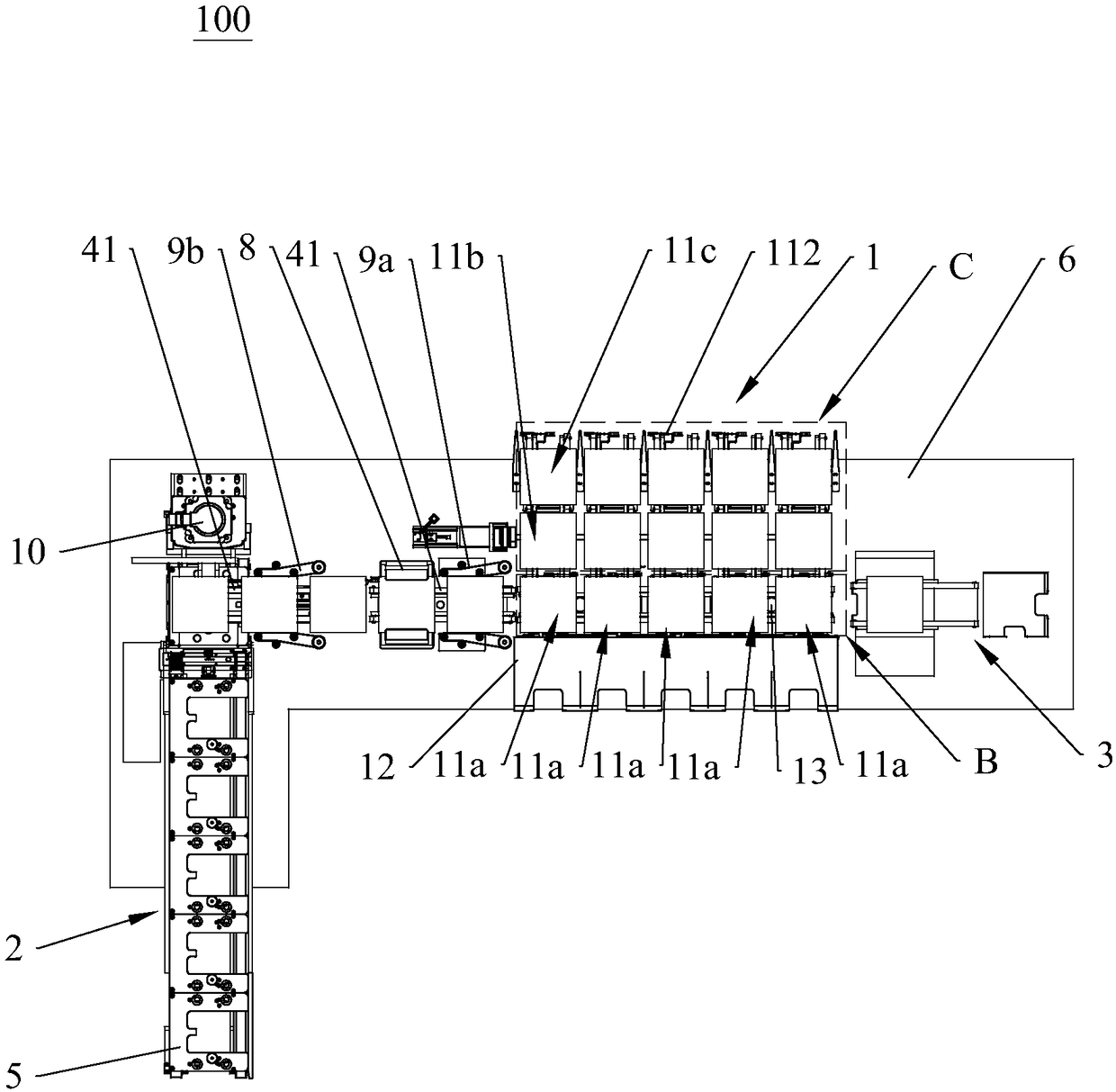

[0035] see Figure 1-3As shown, the single-side unloading machine 100 of the present invention includes a silicon wafer transmission mechanism 1 , a detection mechanism 3 , a guiding mechanism 9 , a wafer feeding mechanism 4 , a carrier 5 and a frame 6 . The silicon wafer transmission mechanism 1, the detection mechanism 3, the guiding mechanism 9 and the wafer delivery mechanism 4 are fixed on the frame 6. The silicon wafer transmission mechanism 1 includes the first transmission parts 11 arranged in a matrix, and the first transmission parts in the first row 11 is arranged in transverse transmission and is located between the second transmission member 41 and the detection mechanism 3, the first transmission members 11 in the remaining r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com